Controllable type coal clean burning device

A clean combustion and controllable technology, applied in combustion equipment, lighting and heating equipment, grain processing, etc., can solve the problems of reducing coal processing efficiency, imperfect structural design, polluting air, etc., and achieve simplified processing steps and safe design Reasonable, the effect of reducing the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

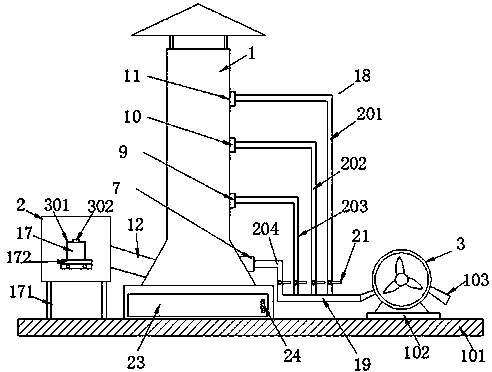

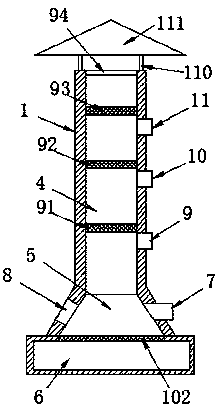

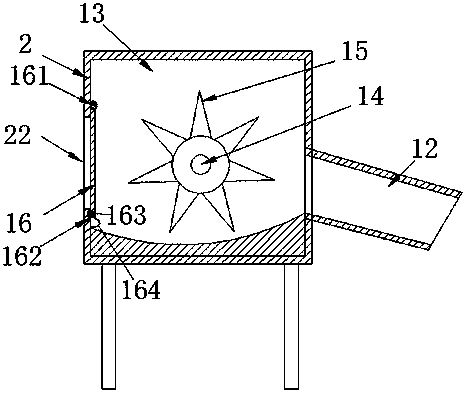

[0018] like Figure 1-3 As shown in the figure, a controllable coal clean burning device of the present invention includes a mounting seat 101, a combustion furnace main body 1, a pulverizing box 2 and a blower 3 fixed on the mounting seat 101. There are graded combustion chambers 4, initial combustion chambers 5 and ash falling chambers 6 in sequence from top to bottom. The left and right end surfaces of the combustion initial chamber 5 are respectively provided with a first supplemental gas inlet 7 and a combustion raw material inlet 8, and the outside of the burner main body 1 corresponds to the right end surface of the staging combustion cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com