Construction method of 3D polycrystalline microstructure material model based on FEAP

A material model and microstructure technology, applied in the direction of instrumentation, design optimization/simulation, calculation, etc., can solve problems such as non-generality, complex modeling methods, heavy workload, etc., and achieve the effect of strong theoretical and practical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

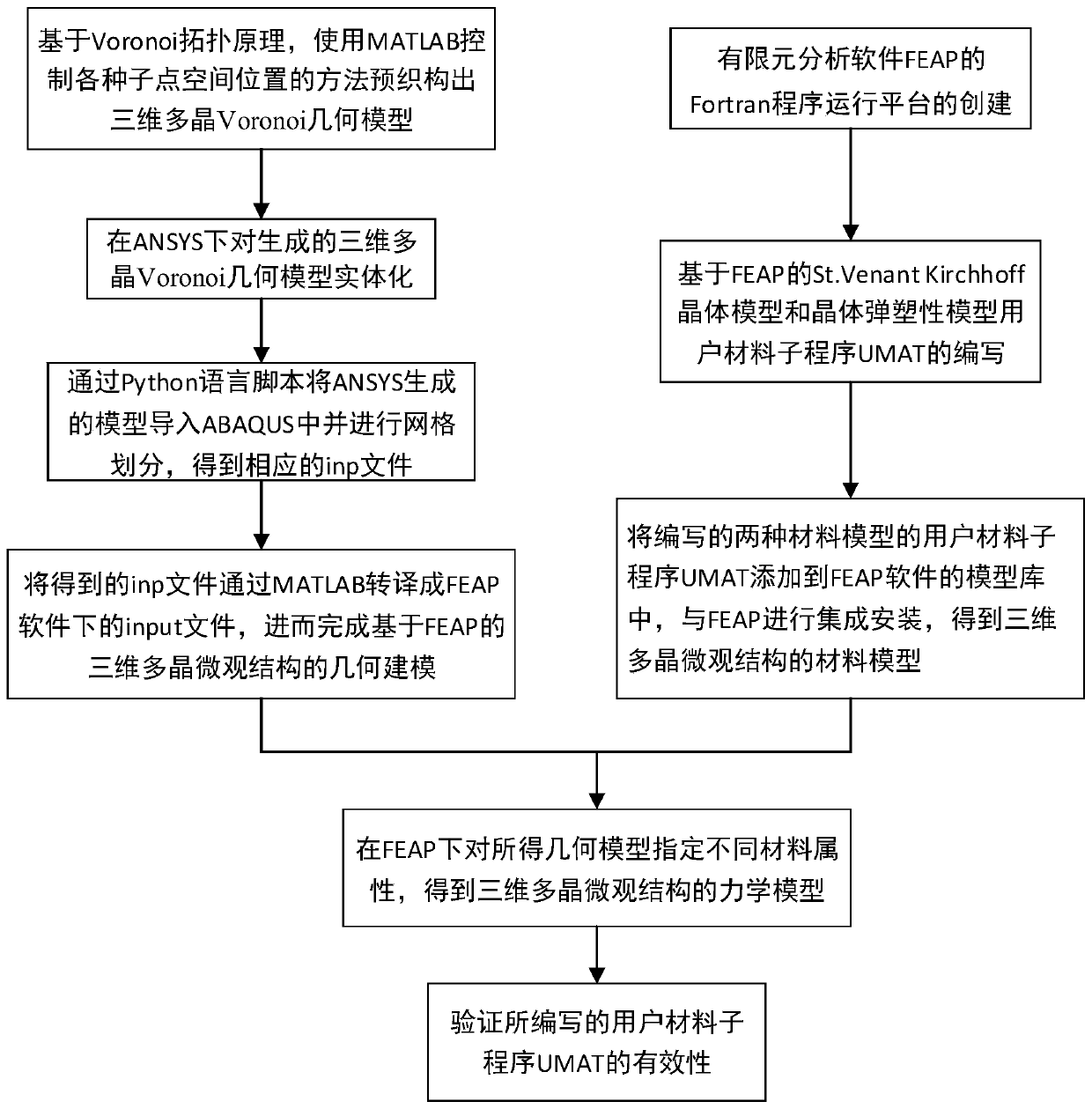

[0069] refer to figure 1 , the present invention is based on the construction method of the three-dimensional polycrystalline microstructure material model of FEAP, and concrete steps are as follows:

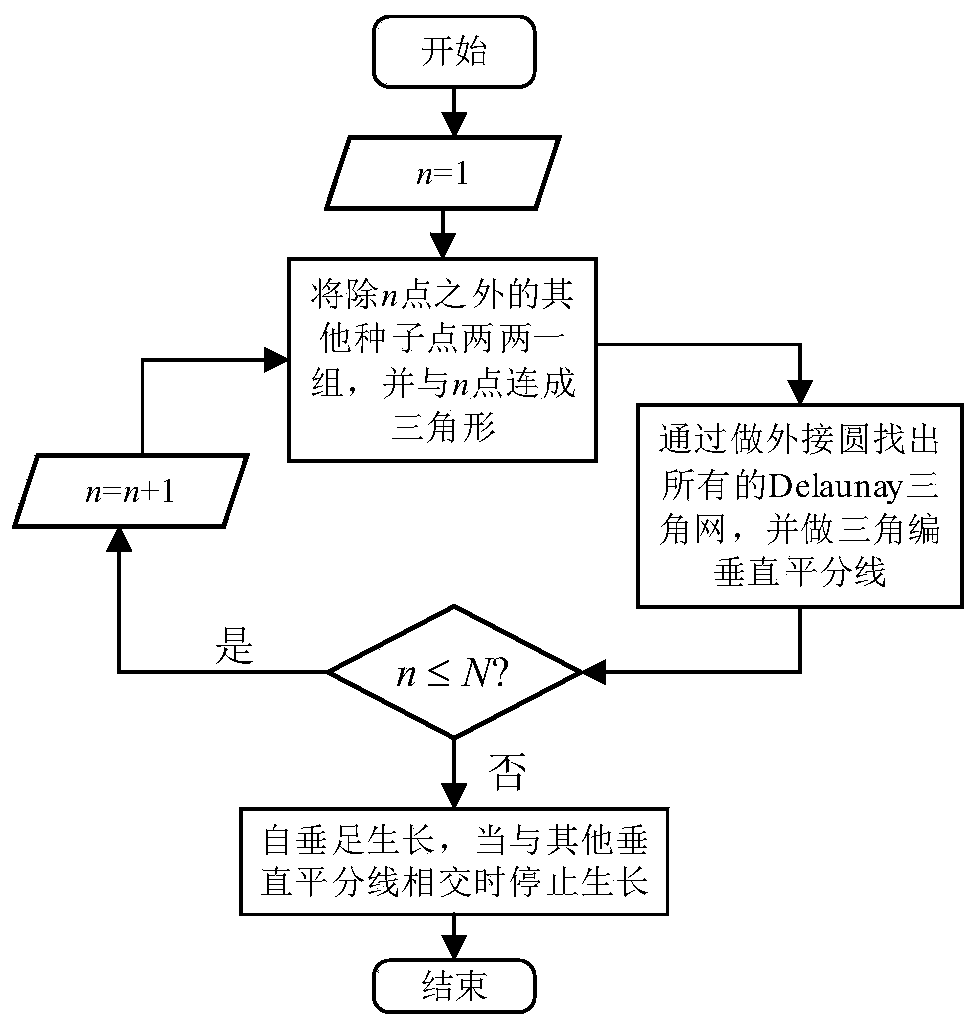

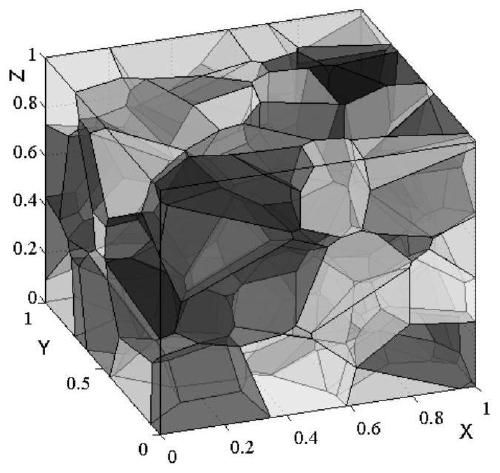

[0070] Step 1. Based on the principle of Voronoi topology, use MATLAB to control the spatial position of various sub-points to pre-texture the three-dimensional polycrystalline Voronoi geometric model

[0071] The algorithm for generating two-dimensional and three-dimensional Voronoi diagrams is integrated in MATLAB, which can be realized by calling the multi-parameter toolbox MPT, so it is only necessary to control the number and position of the generated seed points through the program, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com