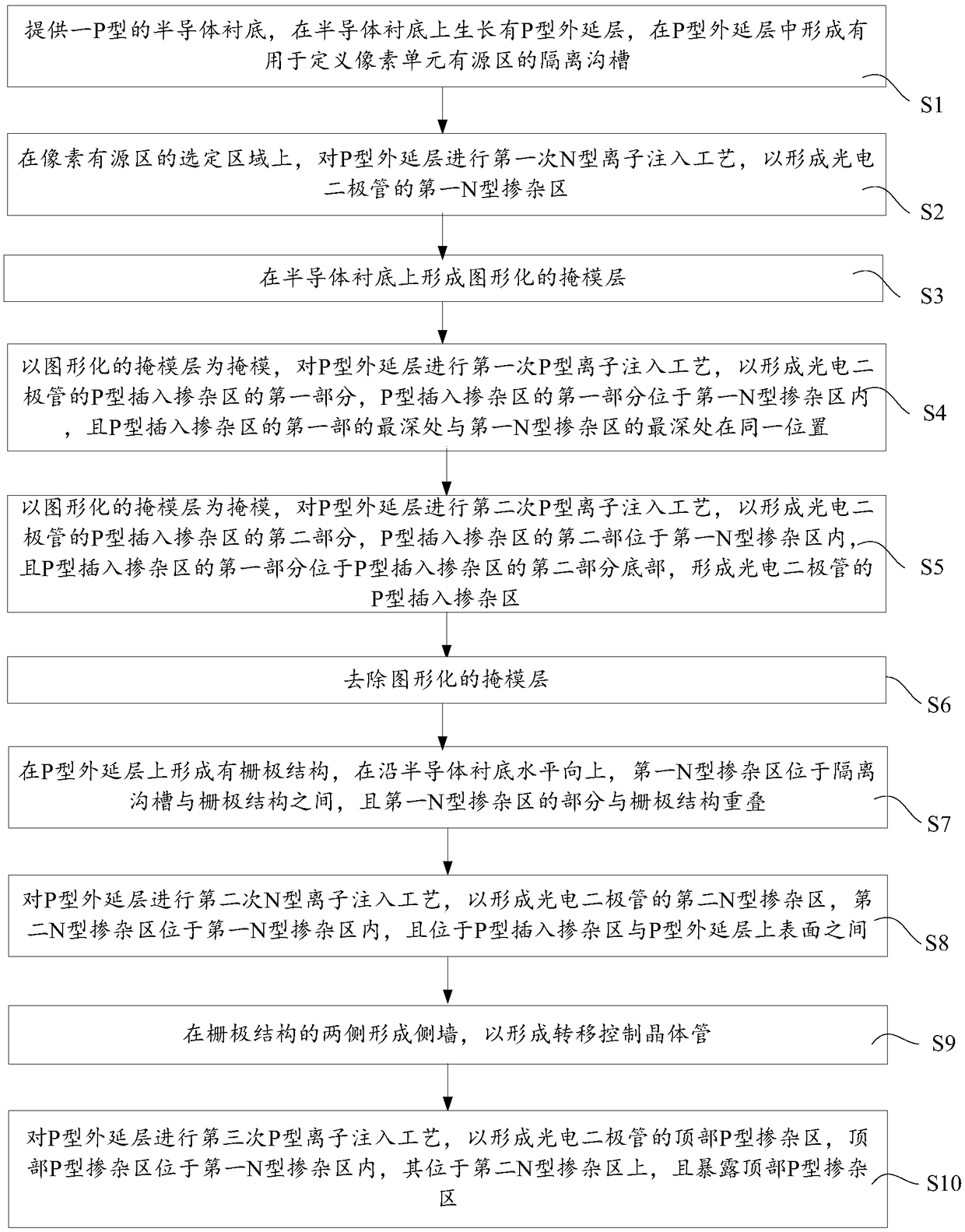

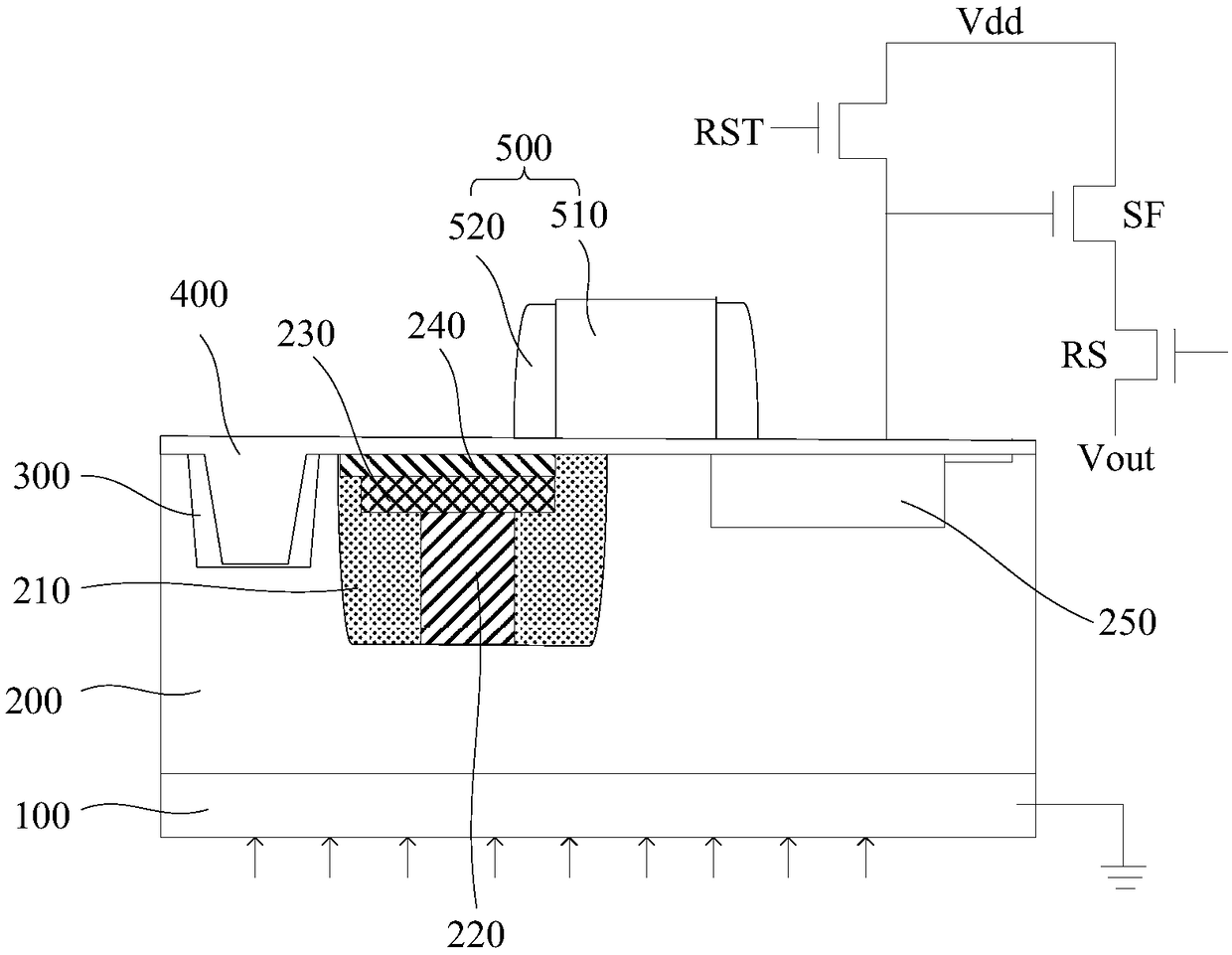

Back-illuminated CMOS image sensor and forming method thereof

An image sensor, back-illuminated technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of reducing the charge collection volume and quantum efficiency of photodiodes, and achieve the effect of increasing the full well capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] As described in the background technology, with the continuous reduction of pixel size, the pixel area is also reduced, so that the maximum signal charge that can be accommodated in the charge collection potential well of a photodiode (Photo-Diode, referred to as PD) is the full well capacity (abbreviation, well capacity) is suppressed, and the suppression of the well capacity will deteriorate the dynamic range, signal-to-noise ratio and sensitivity of small-sized pixels, and these indexes will directly affect the imaging quality of small-sized pixels.

[0026] The inventors have found that when the pixel size decreases, the junction depth of the PN junction of the photodiode becomes shallower, and this change affects the well capacity and quantum efficiency of the photodiode, thereby affecting the pixel performance of the image sensor.

[0027] Based on the above research, the present invention provides a back-illuminated CMOS image sensor and its forming method, by per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com