An integrated structure of rectifier bridge rear cover

An integrated technology of rectifier bridge, applied in the field of integrated structure of rectifier bridge back cover, can solve the problems of low output performance of alternator, small heat dissipation area of rectifier bridge plate, large axial dimension of alternator, etc., and achieve improvement Effects of service life, small size, and axial size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

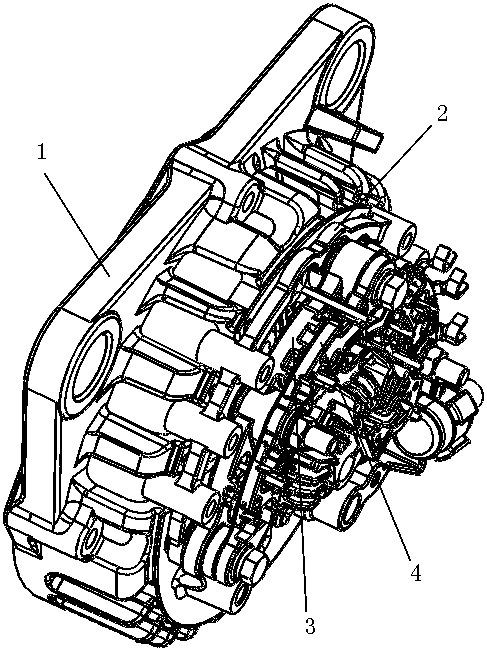

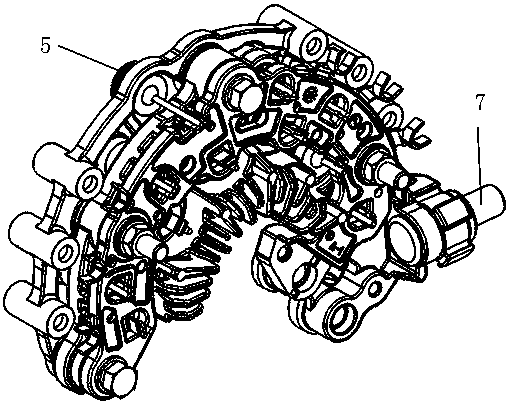

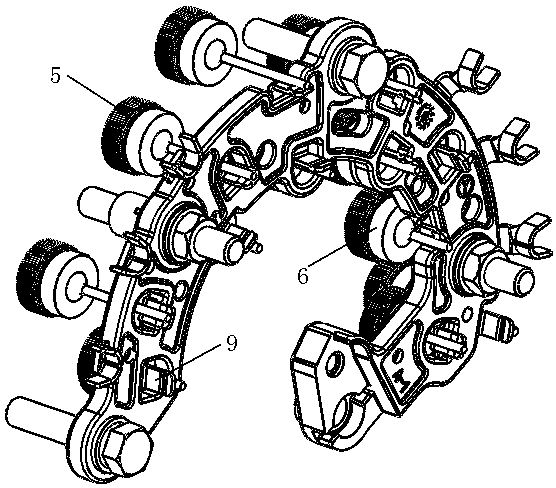

[0025] Such as Figure 1 to Figure 6 As shown, an integrated structure of the rear cover of a rectifier bridge includes a motor rear cover 1, a rectifier bridge assembly connected to the motor rear cover 1, and the rectifier bridge assembly includes a six-phase rectifier bridge. The phase rectifier bridge includes six first diodes 5 press-fitted on the end cover 1. The six-phase rectifier bridge adopts an integrated structure with the rear end cover of the motor, and the first diode is press-fitted into the rear end cover of the motor, so that the heat dissipation area of the diode is large, the heat dissipation performance is better, and the service life of the diode is improved.

[0026] The rectifier bridge assembly specifically includes a plastic guard plate 2 connected to the rear end cover 1 of the motor, a heat dissipatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com