Multi-array coil eddy current probe and switching device

A technology of eddy current probes and array coils, which is applied in the field of eddy current probes to achieve the effects of preventing noise, improving reliability and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, the present invention will be described in detail.

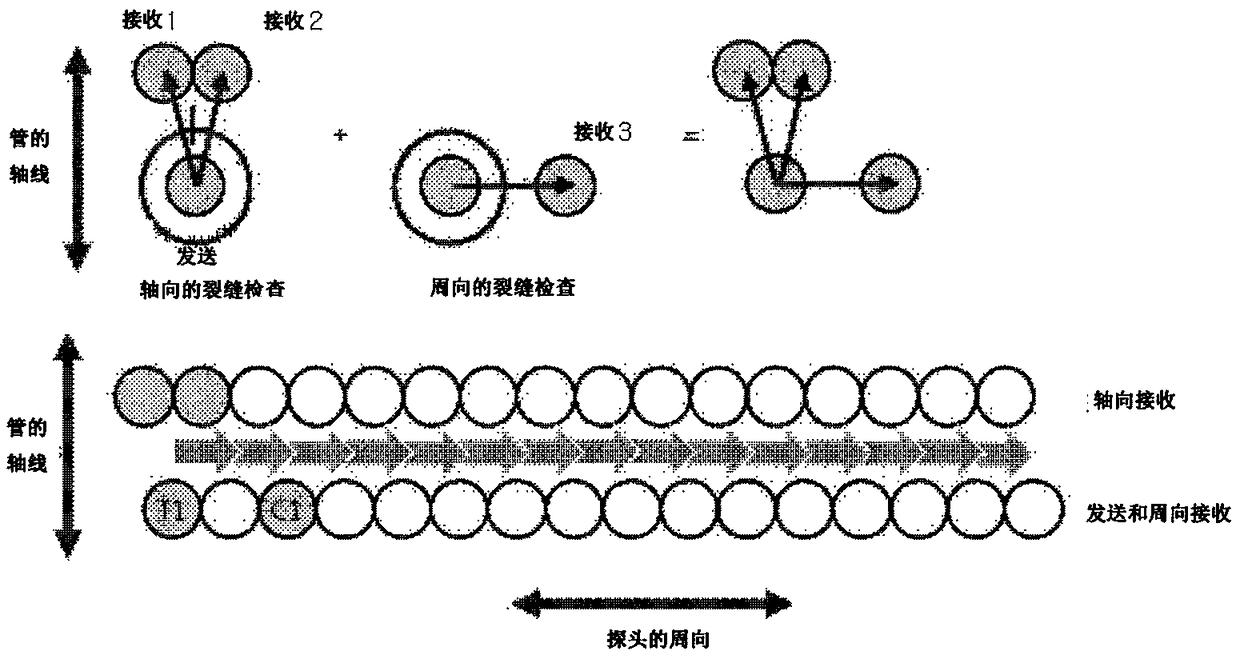

[0047] The array type eddy current probe capable of inspecting tubes of heat exchangers according to the present invention has transmission and circumferential inspection coils formed in a rectangular shape in the axial direction to increase crack detection sensitivity in the circumferential direction.

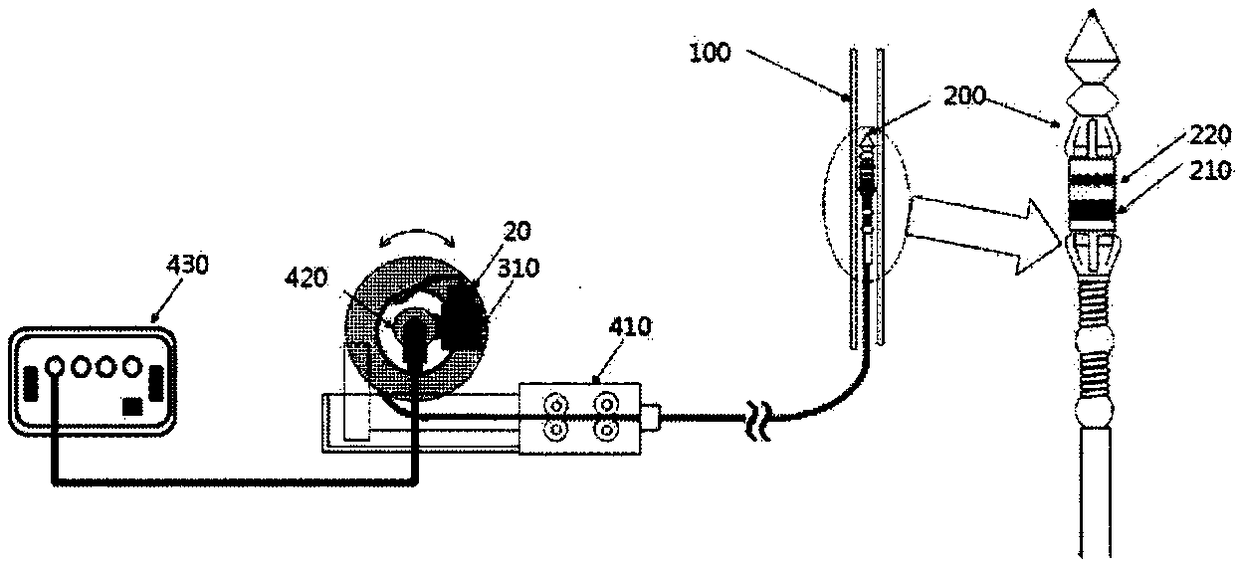

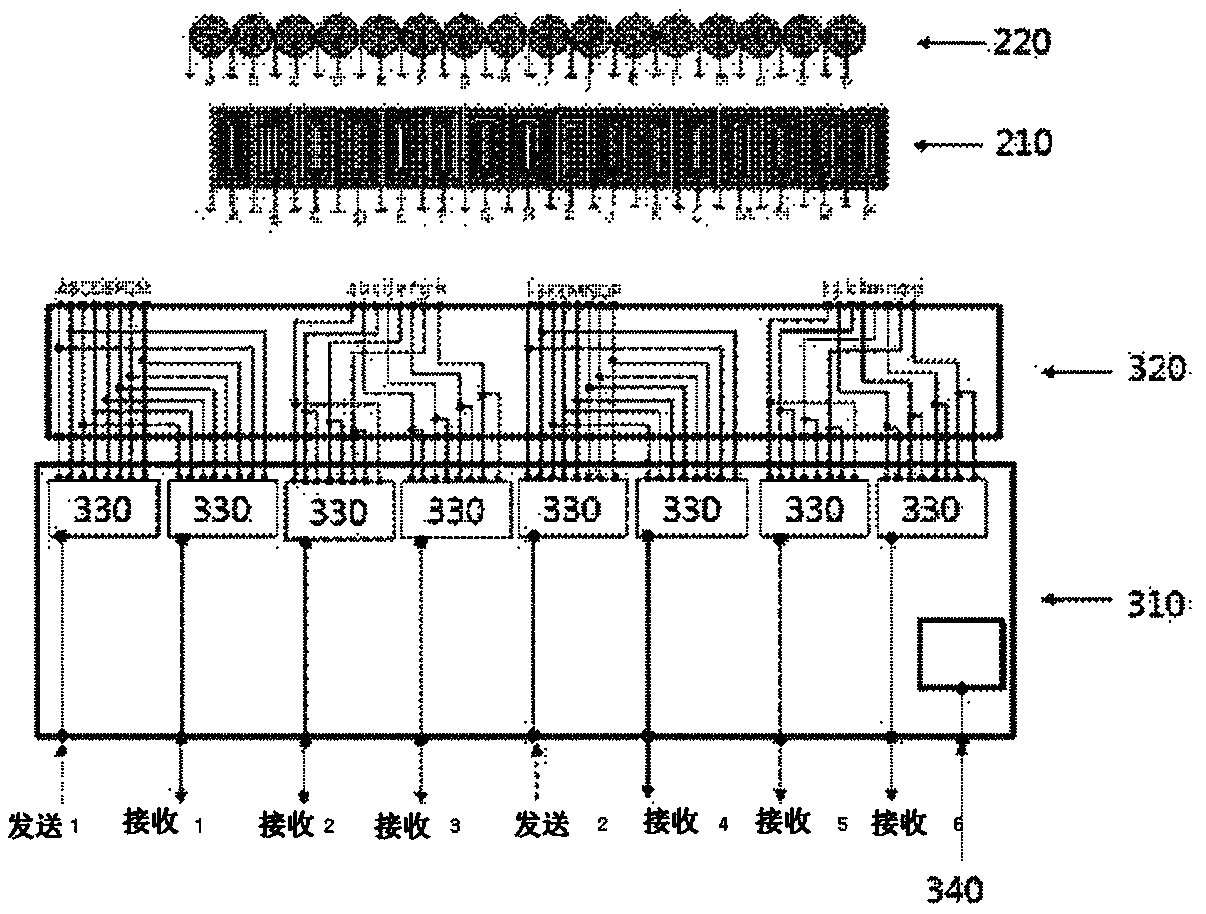

[0048] In the configuration of the array type eddy current inspection system, the eddy current probe of the array coil and the switching device are separated independently from each other, and the switching device is arranged between the array type eddy current probe and the slip ring to reduce the number of channels of the slip ring.

[0049] Such as figure 2 As shown, since the probe inserter for inserting / extracting the probe is equipped with a rotating part, a slip ring is required to connect the probe to the eddy current inspection equipment. However, slip rings with multiple channels are expensive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com