Air oven

An oven and air technology, applied in roaster/barbecue grids, kitchen utensils, household utensils, etc., can solve the problems of difficult to meet the requirements of large-volume food baking processing, high surface temperature, and high cost of air fryers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

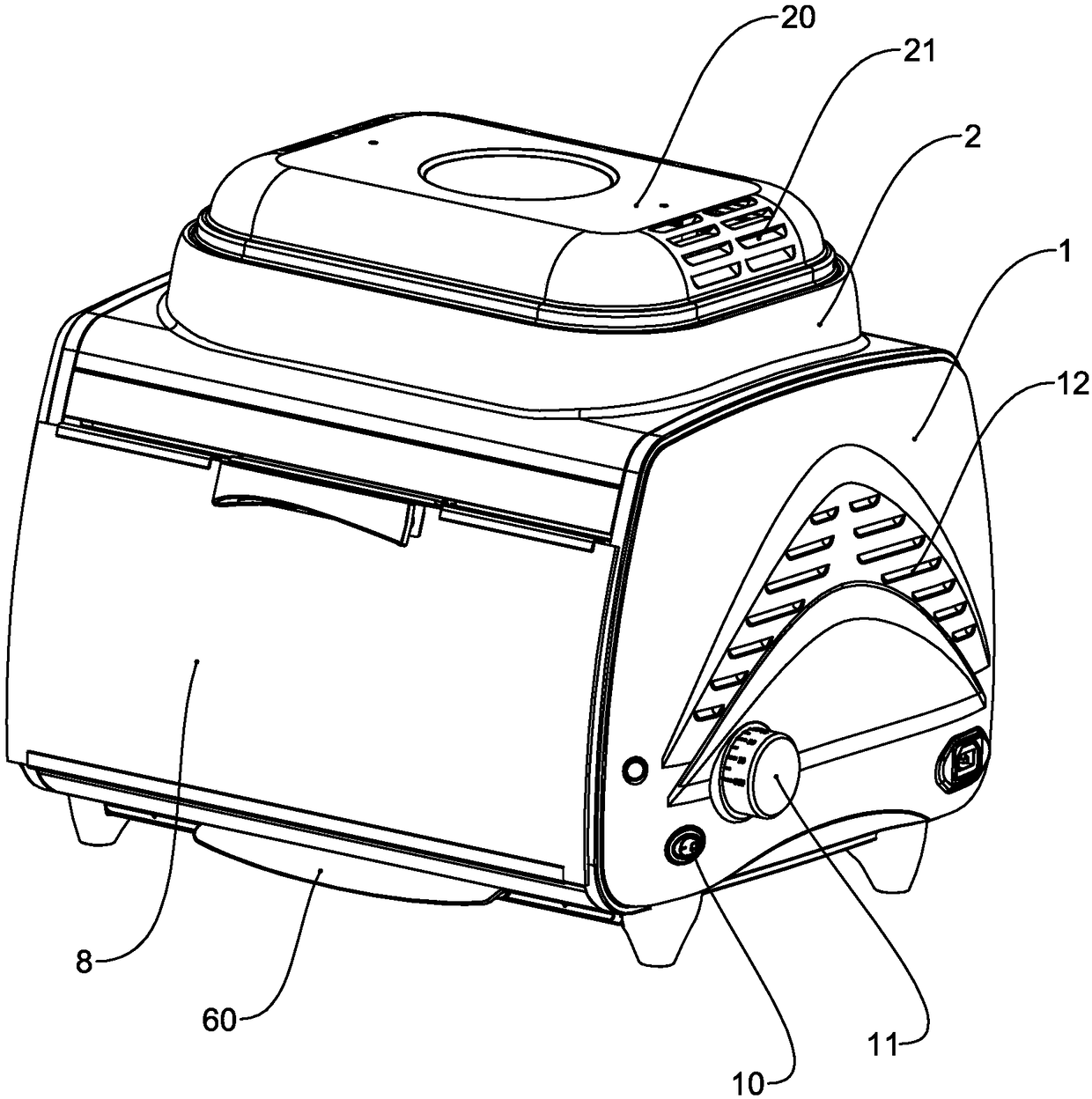

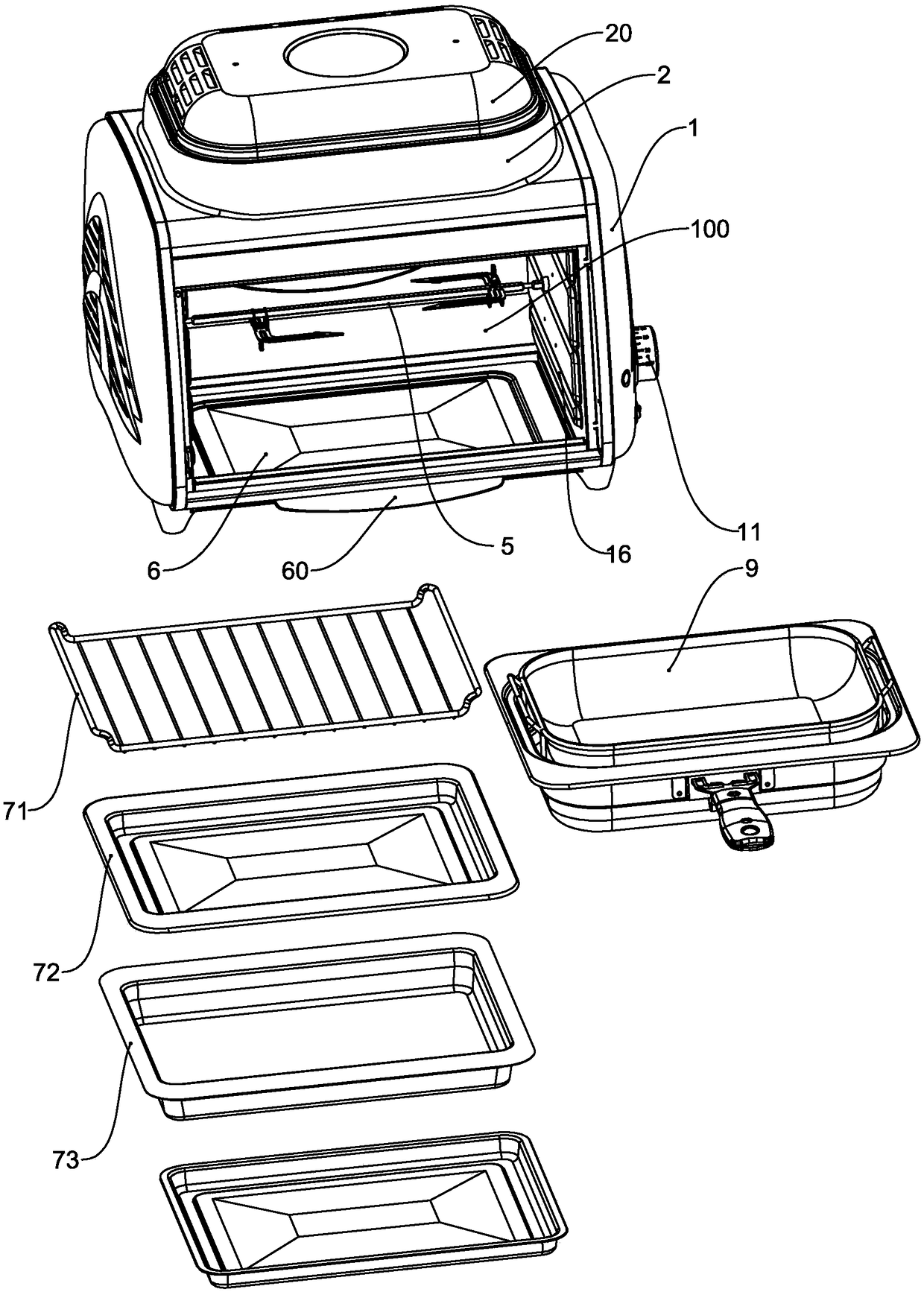

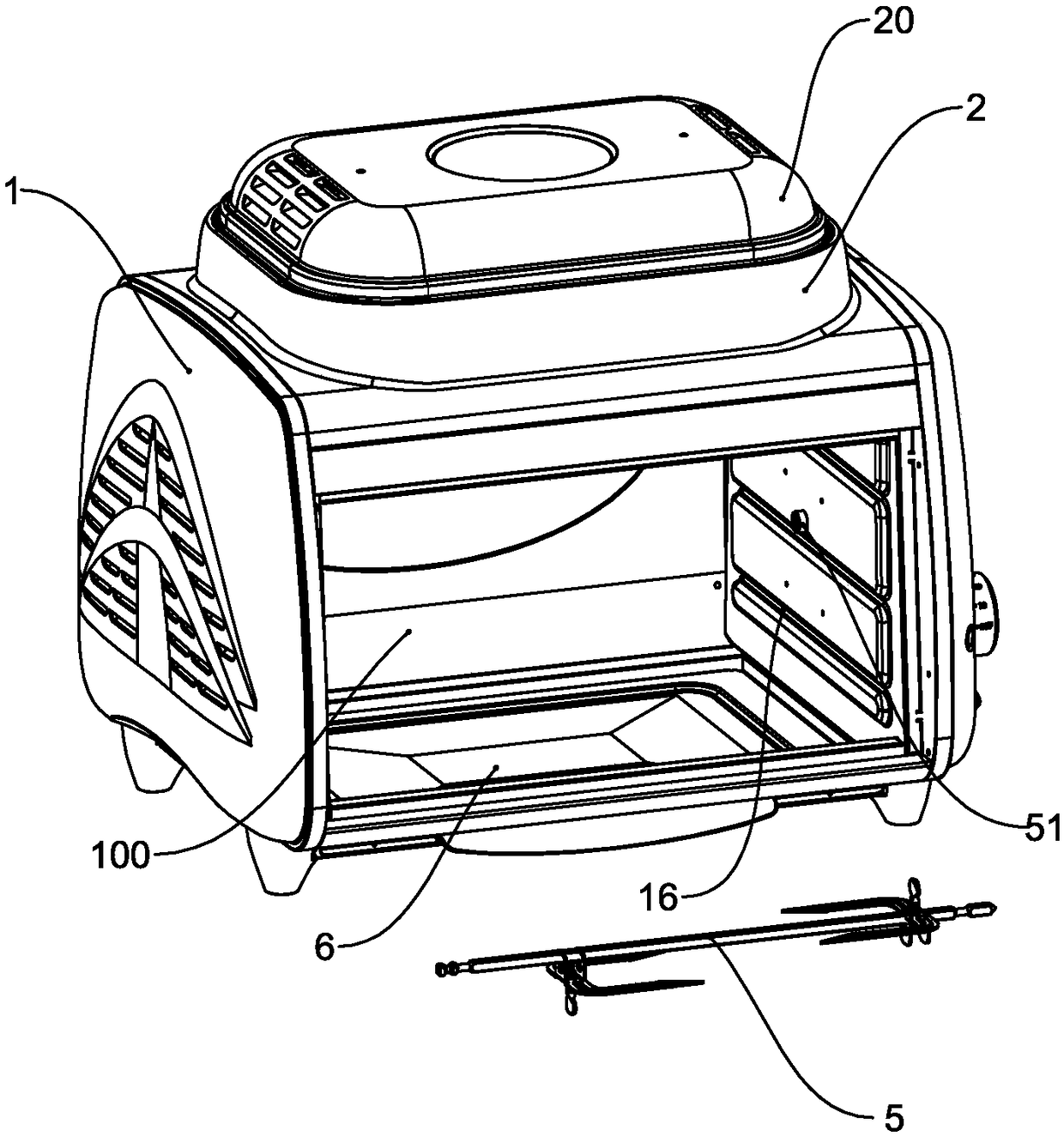

[0027] Such as Figure 1 to Figure 9As shown, the air oven of this embodiment includes a box assembly 1 and an electric control assembly. A heating cavity 100 is formed inside the box assembly 1, and a detachable slag tray 6 is provided at the bottom of the heating cavity 100 for To receive food slag or particles dropped during food processing, the slag receiving tray 6 is plugged and fitted with the bottom plate of the box assembly 1, and the slag receiving tray 6 is provided with a handle 60 for easy access. The electric control assembly includes a switch 10 and a timer 11. In this embodiment, the switch 10 adopts a boat-shaped switch, and the timer 11 adopts a mechanical knob type; The heat insulation chamber 200 is used to thermally isolate the two sides of the heating chamber 100 from the outside world. The outer wall of the heat insulation chamber 200 is provided with several air inlets 12 to communicate with the outside world. There is an opening and closing door 8, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com