Continuous transverse laser cutter

A laser cutting machine, horizontal technology, used in laser welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of gas can not be effectively processed, cutting machine can not be continuously produced, etc., to achieve easy operation, strong applicability, The effect of reducing the interference of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

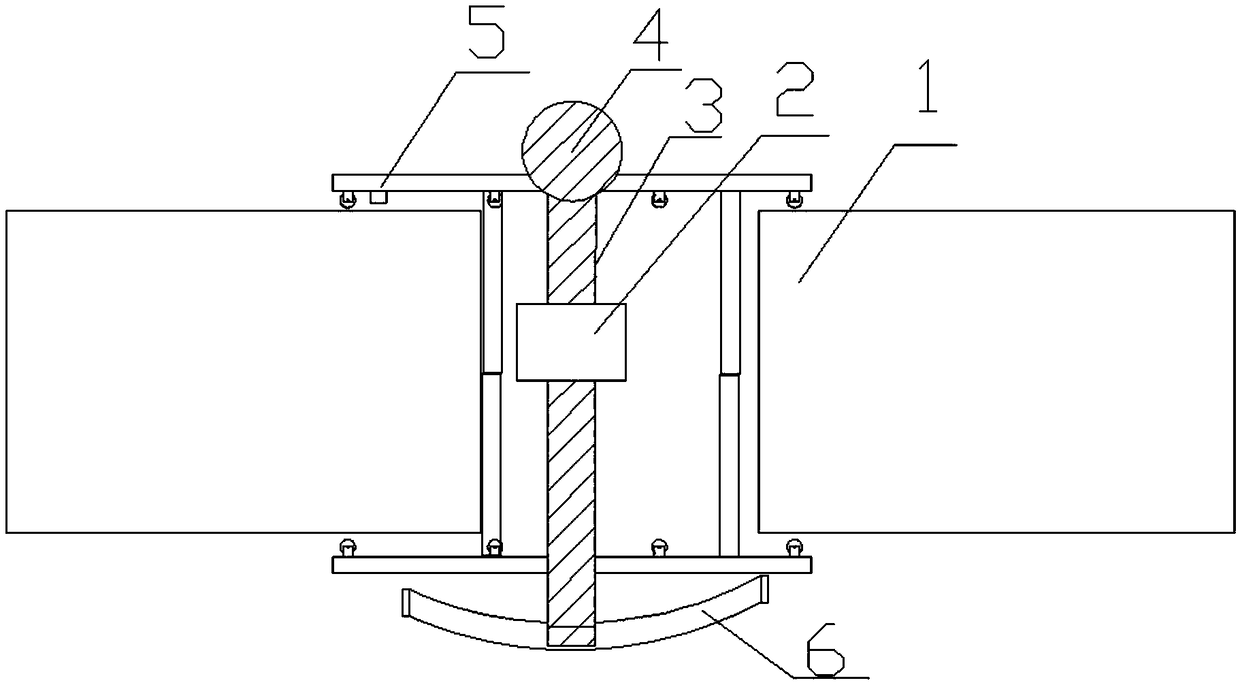

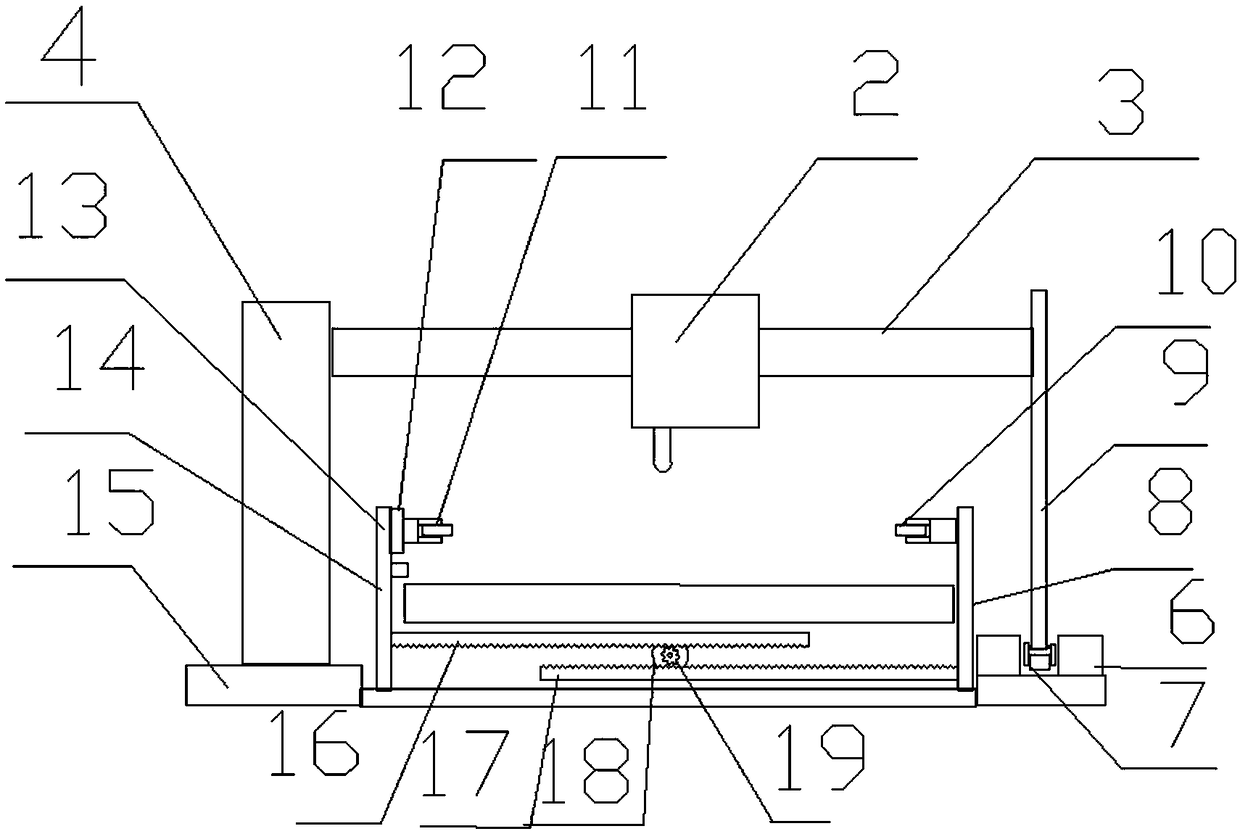

[0022] see Figure 1-3 , a continuous transverse laser cutting machine, including a base 15, a clamping device 5 and a cutting device 2. The base 15 is arranged between the conveyor belts 1 of the production line, and the conveyor belts 1 are used for conveying the products of the production line. The base 15 is horizontally fixed on the ground, and the upper surface of the base 15 is rotatably connected with a vertical support column 4 , and the support column 4 can rotate freely on the base 15 . The upper part of the support column 4 is fixedly connected with the left end of the horizontal slide bar 3 , the slide bar 3 is nested with a cutting device 2 , and the cutting device 2 can slide freely on the slide bar 3 . The right end of the slide bar 3 is fixedly connected to the top of the vertical vertical bar 9 , and the support column 4 and the vertical bar 9 support the slide bar 3 . The bottom of the vertical rod 9 is provided with a driving wheel 7, which is connected t...

Embodiment 2

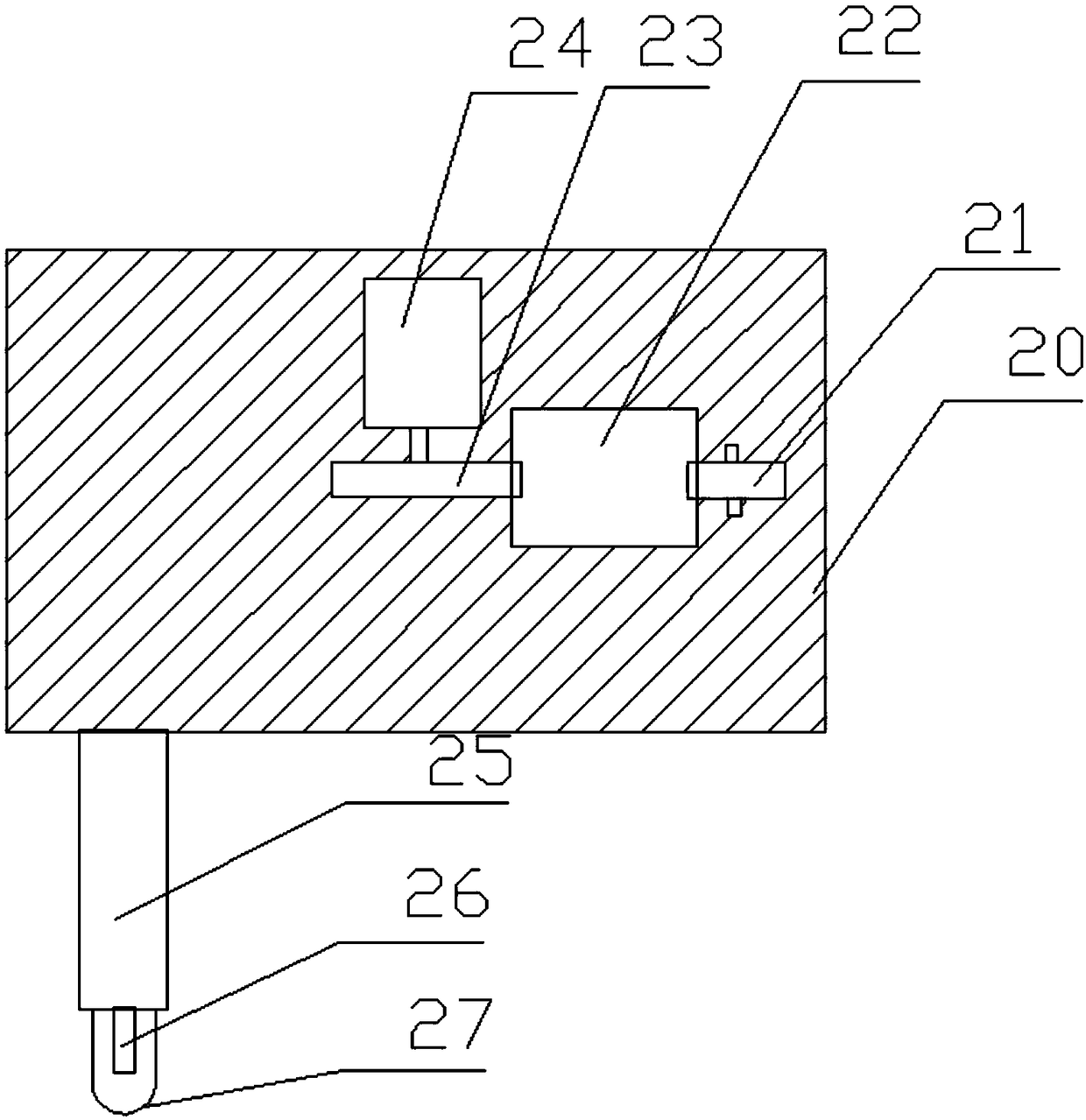

[0027] see Figure 4 , on the basis of Embodiment 1, the left side of the cutting rod 25 is provided with an air suction port 28 on the lower surface of the sliding block 20, the air suction port 28 is a trumpet-shaped structure with the opening downward, and the setting of the air suction port 28 is convenient The gas produced by cutting is sucked away to reduce the harmful gas harm to workers and environmental pollution. The suction port 28 communicates with the cyclone separator 30 provided inside the sliding block 20 through the air pipe 29, and the gas sucked through the suction port 28 enters the cyclone separator 30, and separates the particles and impurities inside the gas. The gas outlet of the cyclone separator 30 is connected to the adsorption layer 31 and the air pump 32 in sequence, and the adsorption layer 31 adsorbs and filters harmful gases in the gas.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap