Warmth-keeping room material and preparation method thereof

A room body and carbon nanotube technology, applied in the field of far-infrared materials, can solve the problems of low utilization rate of resources, waste of resources, poor heating effect, etc.

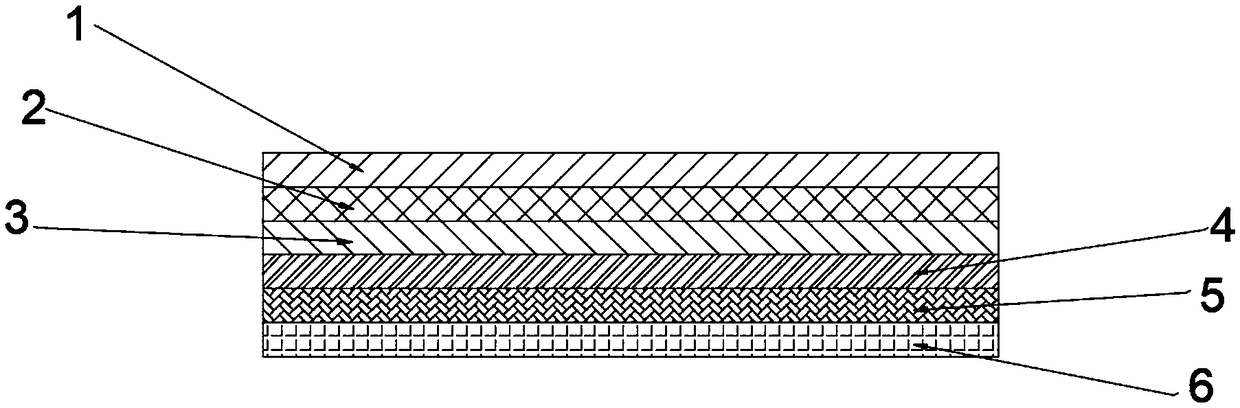

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In the present invention, the preparation method of the carbon nanotube-aramid paper comprises the following steps:

[0034] mixing carbon nanotubes, aramid chopped fibers, aramid fibrids, dispersant, solvent and anionic polyacrylamide to obtain a slurry;

[0035] The slurry is subjected to suction filtration and hot-pressed to obtain carbon nanotube-aramid paper.

[0036] The invention mixes carbon nanotubes, aramid chopped fibers, aramid fibrids, dispersant, solvent and anionic polyacrylamide to obtain slurry;

[0037] In the present invention, the mixing preferably includes the following steps:

[0038] mixing aramid chopped fiber, dispersant I and solvent I to obtain aramid chopped fiber slurry;

[0039] mixing aramid fibrids, dispersant II and solvent II to obtain aramid fibrid slurry;

[0040] Mixing the aramid chopped fiber slurry with the aramid fibrid slurry to obtain the aramid fiber slurry;

[0041] mixing the carbon nanotubes, dispersant III and solvent ...

Embodiment 1

[0072] Preparation of carbon nanotube-aramid paper:

[0073] 5g of para-aramid chopped fibers, 0.1g of sodium dodecylbenzene sulfonate and 500g of water were mixed, and beaten by a beater for 10 minutes to obtain a para-aramid chopped fiber slurry;

[0074] Mix 5 g of para-aramid fibrid fiber, 0.1 g of sodium lauryl sulfate and 500 g of water, sonicate for 30 minutes, and beat for 10 minutes to obtain para-aramid fibrid fiber slurry;

[0075] Mixing the para-aramid chopped fiber slurry and the para-aramid fibrid fiber slurry, shearing treatment for 30 minutes under the condition of 2000r / min, to obtain the aramid fiber slurry;

[0076] 3g of whisker-shaped carbon nanotubes, 0.1g of sodium lauryl sulfate and 300g of ethanol were mixed, ultrasonicated for 30min, and sheared at 2000r / min for 30min to obtain a carbon nanotube dispersion;

[0077] The aramid fiber slurry, the carbon nanotube dispersion and 0.3 g of anionic polyacrylamide were mixed, and sheared at 2000 r / min for 3...

Embodiment 2

[0085] Preparation of carbon nanotube-aramid paper:

[0086] 6g of para-aramid chopped fibers, 0.1g of sodium dodecylbenzene sulfonate and 600g of water were mixed, and beaten by a beater for 15 minutes to obtain a para-aramid chopped fiber slurry;

[0087]Mix 4g of para-aramid fibrid fiber, 0.08g of sodium lauryl sulfate and 400g of water, sonicate for 30 minutes, and beat for 15 minutes to obtain para-aramid fibrid fiber slurry;

[0088] Mixing the para-aramid chopped fiber slurry and the para-aramid fibrid fiber slurry, shearing treatment for 30min under the condition of 1800r / min, to obtain the aramid fiber slurry;

[0089] 5g whisker-shaped carbon nanotubes, 0.15g sodium lauryl sulfate and 400g ethanol were mixed, ultrasonicated for 30min, and sheared at 1800r / min for 30min to obtain a carbon nanotube dispersion;

[0090] The aramid fiber slurry, the carbon nanotube dispersion and 0.6 g of anionic polyacrylamide were mixed, and sheared at 1800 r / min for 30 minutes to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap