Wedge type large-diameter round pipe column lifting and overturning device

A large-diameter, wedge-shaped technology, used in transportation and packaging, load hanging components, etc., can solve the problems of uncontrolled motion, reduce construction progress, danger, etc., achieve good effect of buffering instantaneous kinetic energy, avoid violent shaking, The effect of reverse luck is flexible and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with embodiment:

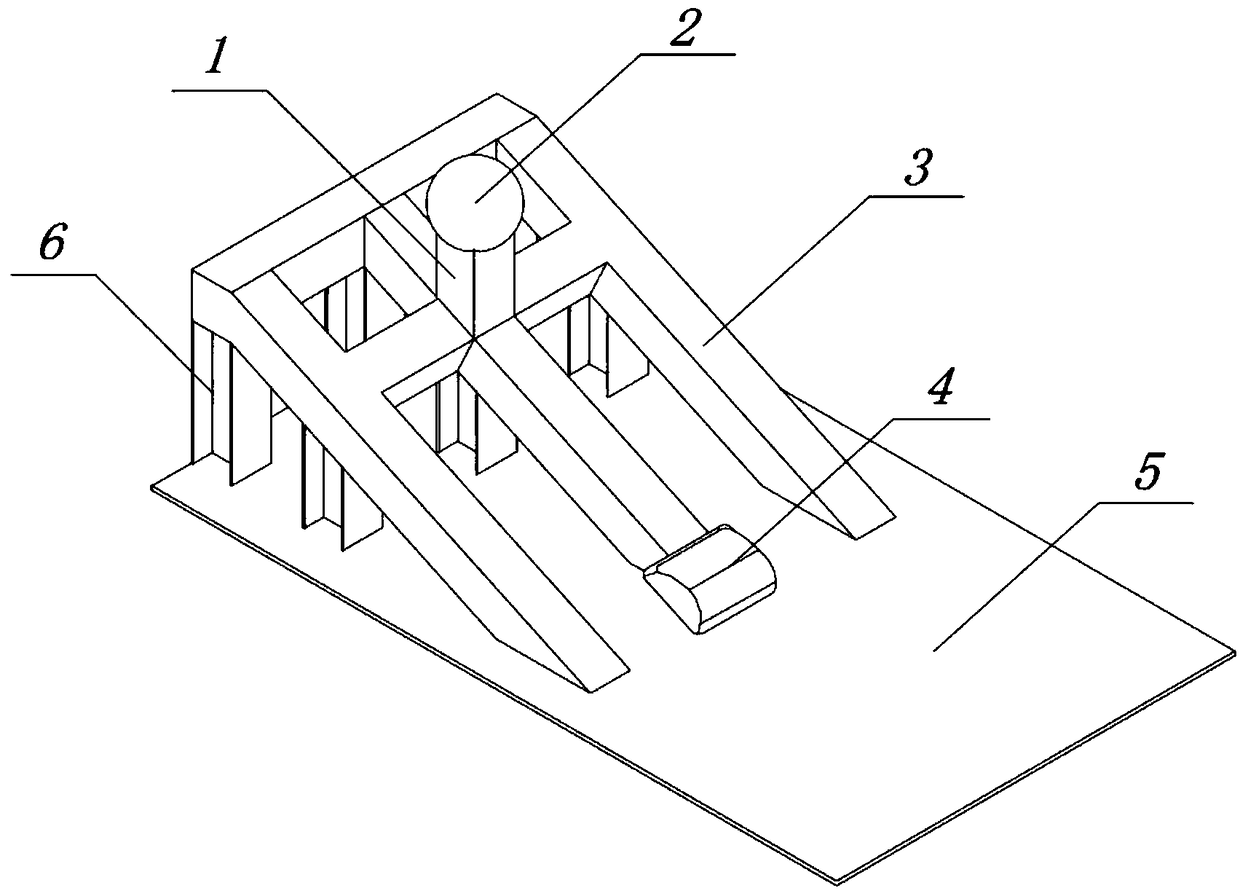

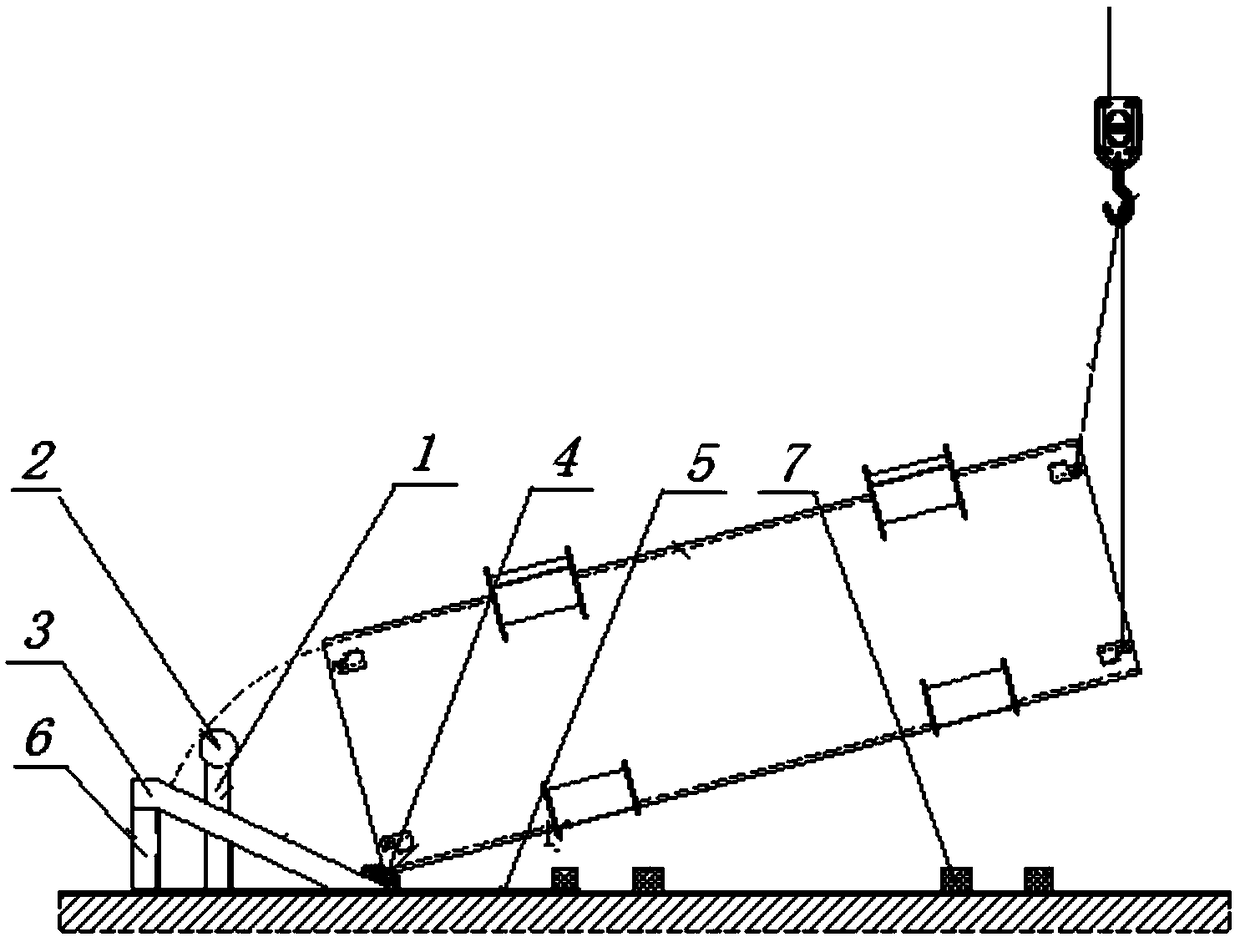

[0020] see figure 1 , the present invention comprises a horizontal load-bearing steel plate 5, an inclined support bracket 3 is arranged on the upper surface of the load-bearing steel plate 5, there is an included angle between the support bracket 3 and the load-bearing steel plate 5, and the included acute angle is 25°, and the lower end of the support bracket 3 It is fixedly connected with the load-bearing steel plate 5, and a support base 6 is fixedly connected between the support bracket 3 and the load-bearing steel plate 5. A support rod 1 perpendicular to the load-bearing steel plate 5 is arranged on the upper surface of the support bracket 3, and the upper end of the support rod 1 is wrapped Rubber-covered ball 2, a pad assembly for cushioning the round pipe column is provided on the outer side of the lower end of the support bracket 3, and a support block for supporting the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com