Automatic control domestic garbage pyrolysis gasification furnace

A technology for pyrolysis gasification and domestic waste, applied in the field of domestic waste recycling, can solve the problems of complex water seal structure of air supply pipeline, unclear state of material layer in furnace, large gas tar content, etc. Operation, convenient disassembly and maintenance, and the effect of reducing motor energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be more clearly and completely described below through the embodiments and in conjunction with the accompanying drawings.

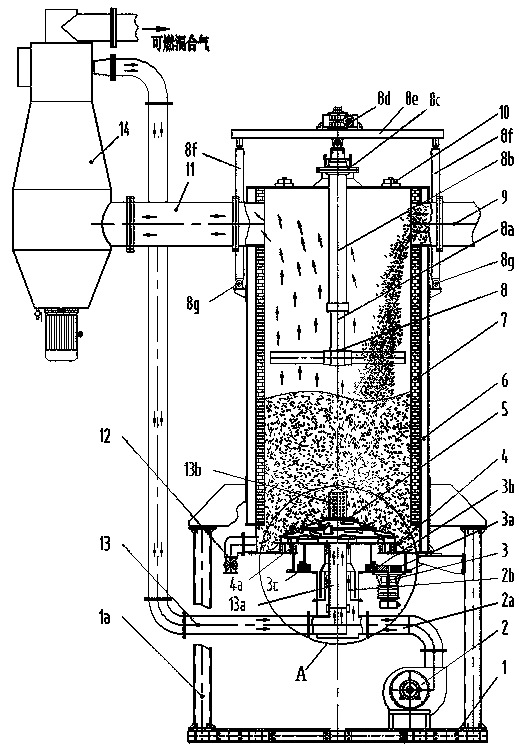

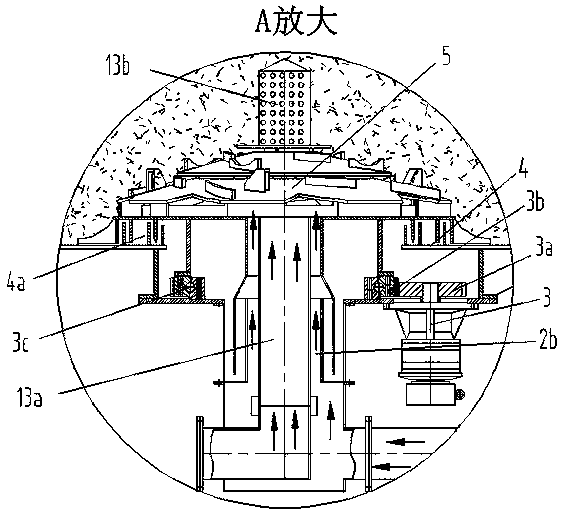

[0013] figure 1 , 2 It shows a structural diagram of an automatically controlled domestic waste pyrolysis gasifier. In the figure, this automatically controlled household waste pyrolysis gasification furnace includes a furnace body base 1, a furnace body 6, a material distributing device, an air supply device, an air distribution disk drive device and a combustible gas oil and gas return device. The base 1 of the furnace body is fixedly connected to the furnace body 6 through the furnace body legs 1a. The inner side of the furnace body 6 is provided with a refractory insulation wall 7, the bottom is provided with an air distribution pan 5 and an automatic slag discharge valve 12, and the top is provided with a support sleeve 8b. The shaft sleeve supports 8c and the explosion-proof valve 10, and the top side is provided ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap