Assembled planting roof system

A roofing system and prefabricated technology, applied in the direction of roofing, roof covering, roof decoration, etc., can solve the problems of poor waterproof effect, inconvenient installation, inflexible layout, etc., to relieve waterproof pressure, reduce weight, and flexible layout. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

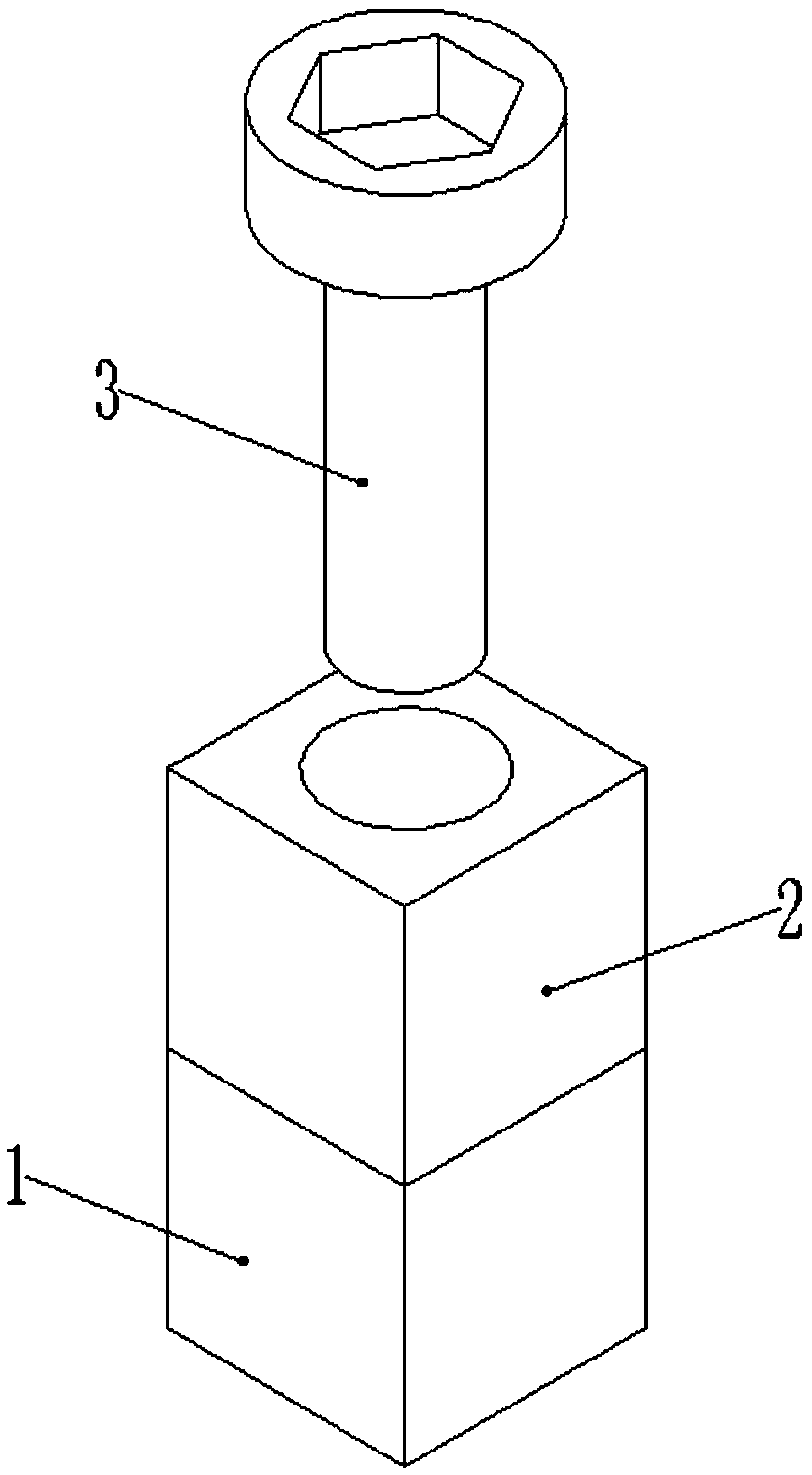

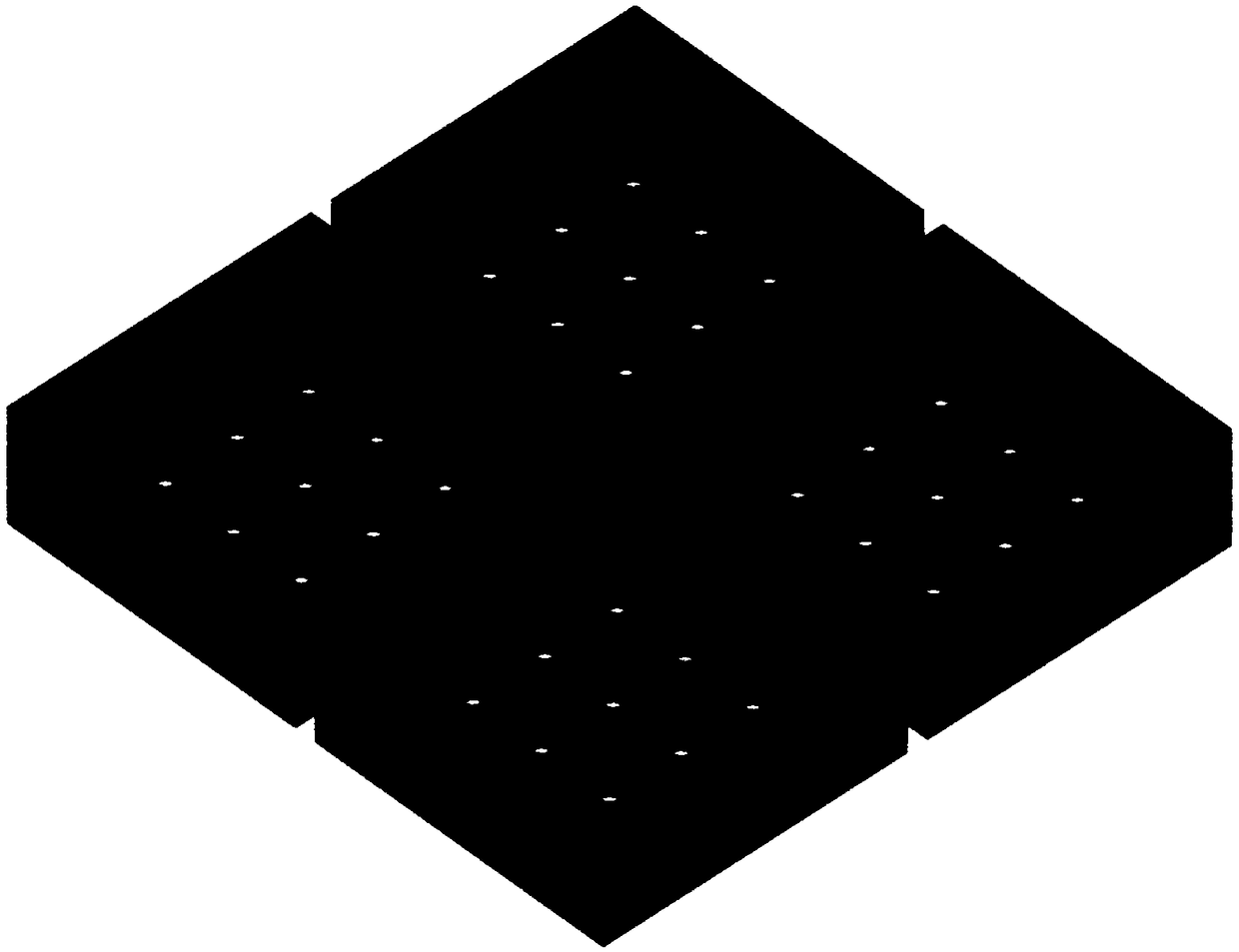

[0029] Such as Figure 1-5 A prefabricated planting roof system shown includes a plurality of box units and fixing components for planting vegetation, the box unit is a square box with an open top; the box unit includes four side panels, and the four side panels include The first side plate and the second side plate are arranged oppositely; the first connecting block 1 is fixed on the first side plate, and the second connecting block 2 is fixed on the second side plate; multiple box units are spliced It is covered on the roof, wherein the first connection block 1 and the second connection block 2 on any two adjacent box units are installed in cooperation and fixedly connected by a fixing component.

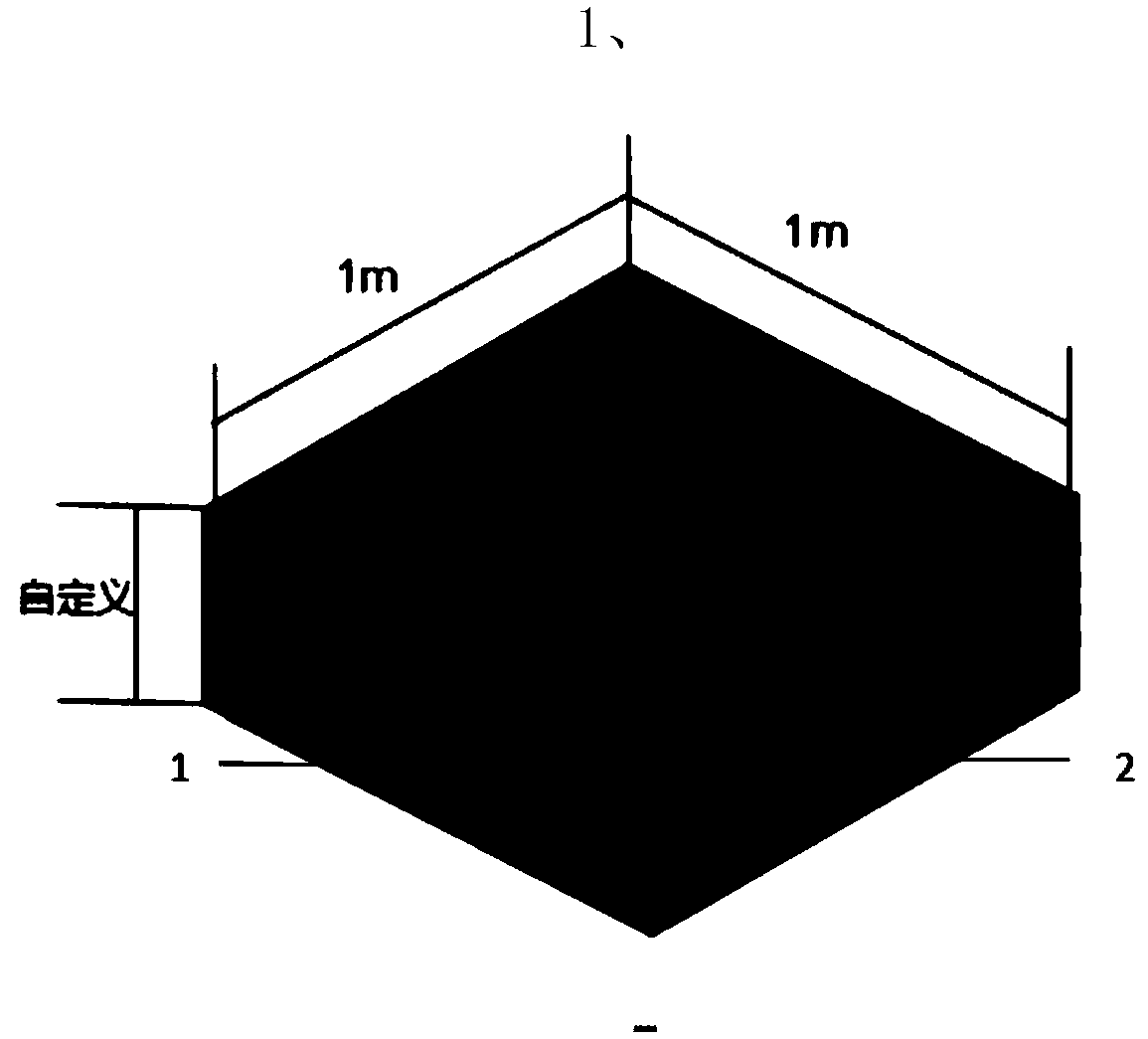

[0030] Specifically, as figure 2 with image 3 As shown, in order to facilitate the splicing of the box unit, the length of the box unit is equal to the width, the specific size is 1 meter, and the height of the box unit needs to be adjusted and customized according to the roof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com