Formwork Erection Method and Formwork Structure of Column Beam and Frame Beam Joint

A formwork technology for frame beams and columns, which is applied in the fields of formwork/formwork/work frame, building structure, and on-site preparation of building components. Shorten the physical construction period, solve the problem of long production cycle and good demoulding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

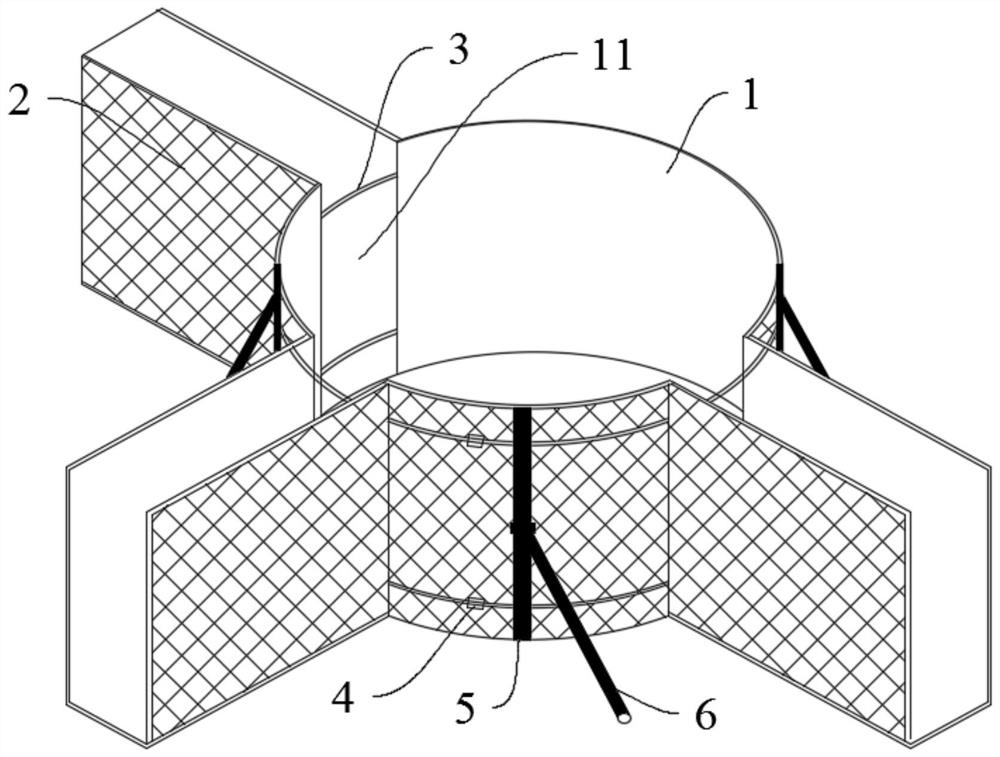

[0026] As shown in the figure, the formwork structure used for the joint construction of cylindrical beams and frame beams is made of wooden formwork. At the connection between the column and the frame beam, the circular column formwork 1 surrounds the formwork of the cylindrical steel bar grid, The frame beam formwork 2 is erected around the steel mesh of the frame beam, the arc-shaped column formwork 1 and the frame beam formwork 2 are connected at nodes, and the connection between the arc-shaped column formwork 1 and the frame beam formwork 2 is provided with a vertical opening 11.

[0027] At the junction of the arc-shaped column formwork 1 and the frame beam formwork 2, nails are nailed from the inside of the arc-shaped column formwork 1 to the end of the frame beam formwork 2 for connection.

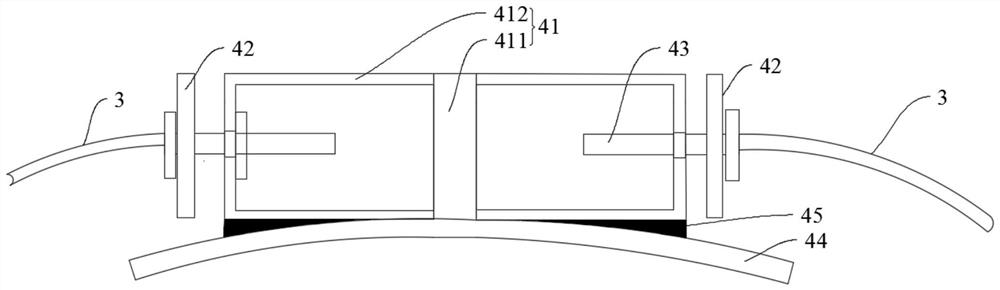

[0028] On the outside of the arc-shaped column formwork 1, several round steel rings 3 for fastening are provided at vertical intervals. An end notch 21 is provided at the joint b...

Embodiment 2

[0037] The formwork erection method of the above-mentioned cylindrical beam and frame beam joint, the method comprises the following steps:

[0038]S1: Production of arc-shaped column formwork: 5mm wooden formwork is used as raw material. If there are several connection points between the column and the frame beam, the arc-shaped column formwork of the corresponding number of sections is cut out. Before cutting, each section of arc-shaped column formwork is accurately measured. According to the radius of the cylinder, the woodworking machinery is used for simple bending processing;

[0039] S2: Installation of arc-shaped column formwork: first install the arc-shaped column formwork around the steel mesh of the cylinder, and use the round steel ring to hoop the arc-shaped column formwork from the outside. Multiple round steel rings can be set, and the vertical spacing is 60cm , to achieve sufficient fixation strength;

[0040] S3: Installation of the frame beam formwork: the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com