Vibration isolation device of power mechanism and electric vehicle including vibration isolation device

A technology for electric vehicles and power mechanisms, applied in power devices, electric power devices, transportation and packaging, etc., to achieve the effects of reducing radiation noise, not being easily damaged, and solving vibration durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

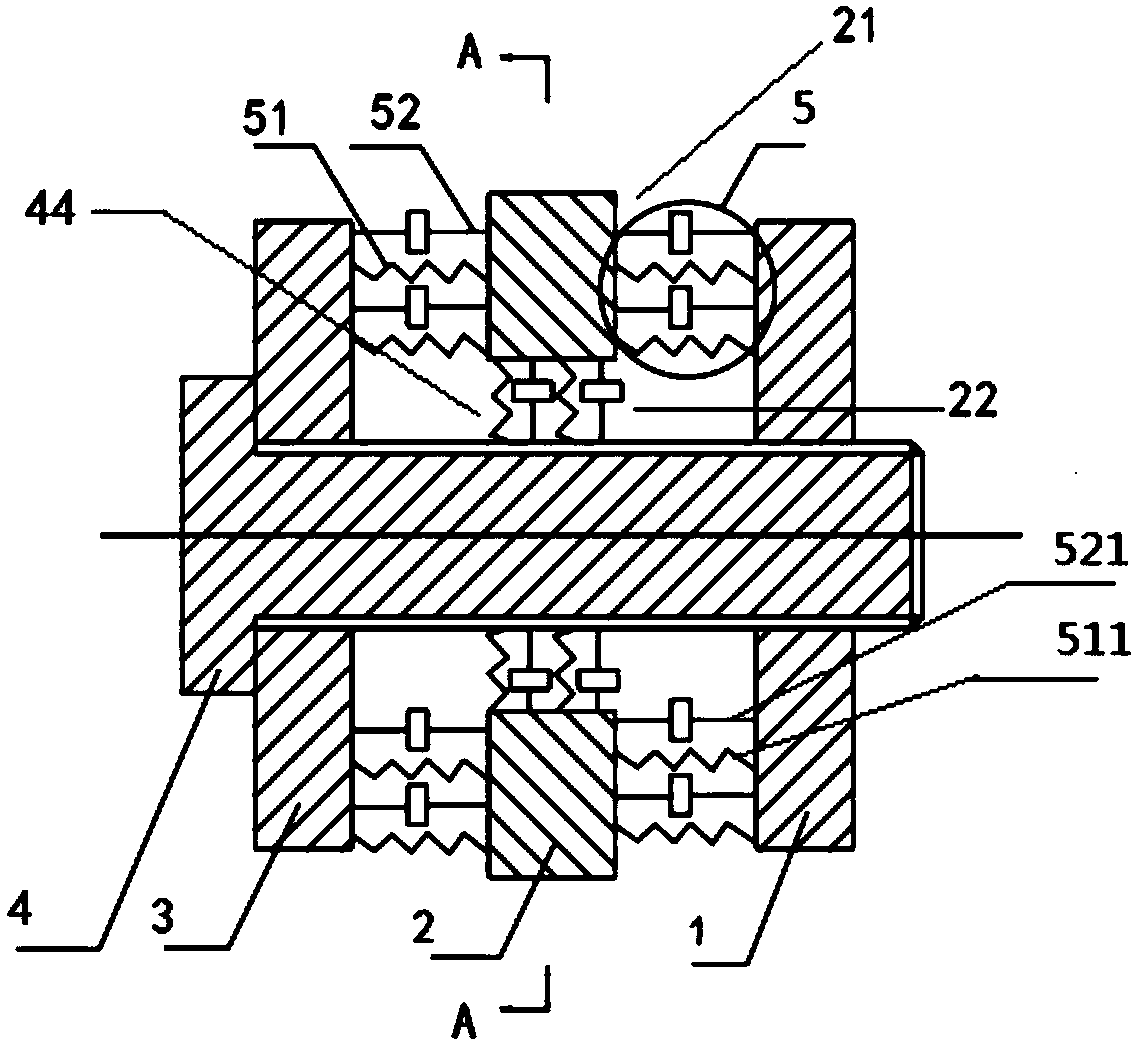

[0041] The casing 3 of the electric power mechanism, the casing 2 of the controller and the limit locking block 1 are arranged along the axial direction of the through bolt 4, and are respectively passed through by the through bolt 4. There is an axial gap 21 between them; a vibration isolation structure 5 is provided in the axial gap 21 to connect the adjacent two. Preferably, a plurality of the vibration isolation structures 5 are arranged in the axial gap 21 and arranged around the circumference of the through bolt 4 .

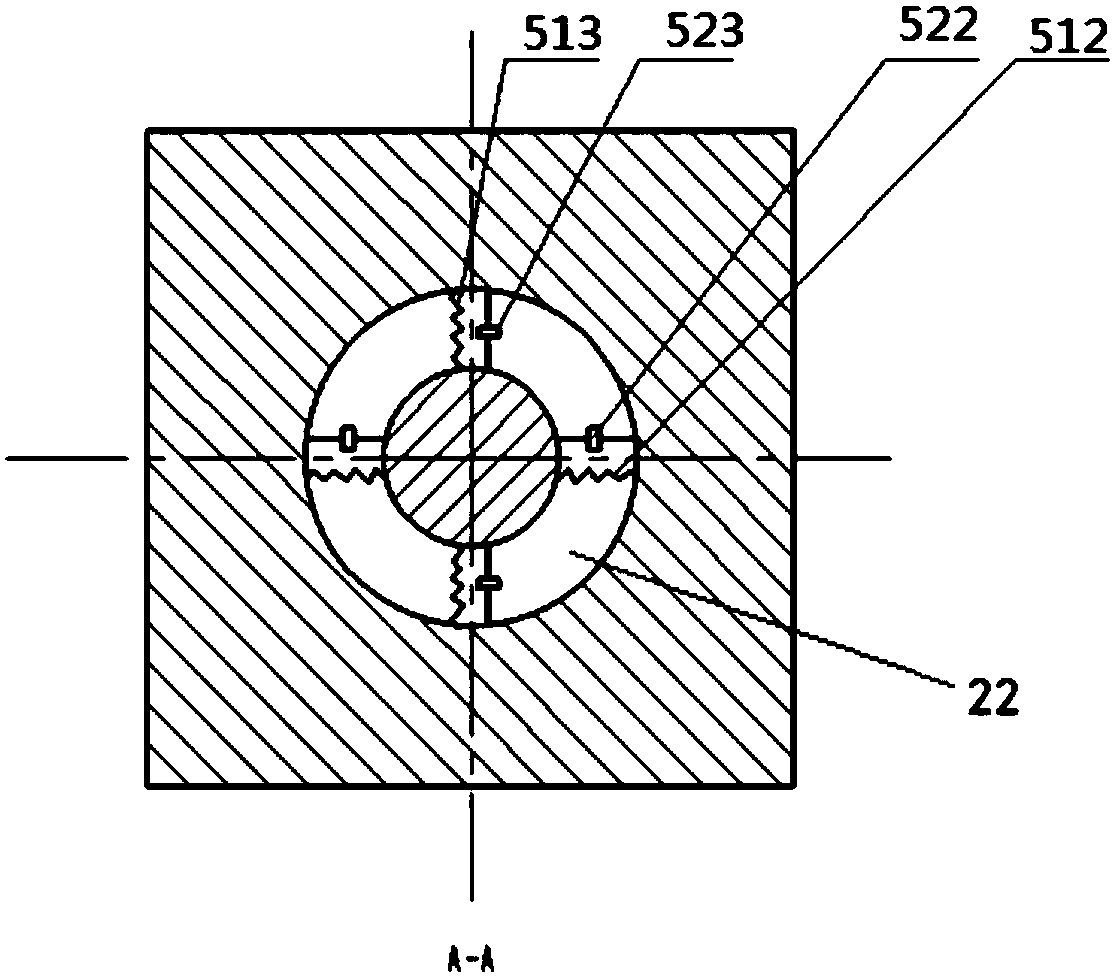

[0042] The housing 2 of the controller has a through hole 41 through which the through-hole bolt 4 passes, and there is a circumferential gap 22 between the through-hole 41 and the through-bolt 4 , and a vibration isolation structure 5 is arranged in the circumferential gap 22 , to connect the housing 2 of the controller with the through bolt 4.

[0043] Preferably, a plurality of vibration isolation structures 5 are arranged in the circumferential gap 22 ...

Embodiment 2

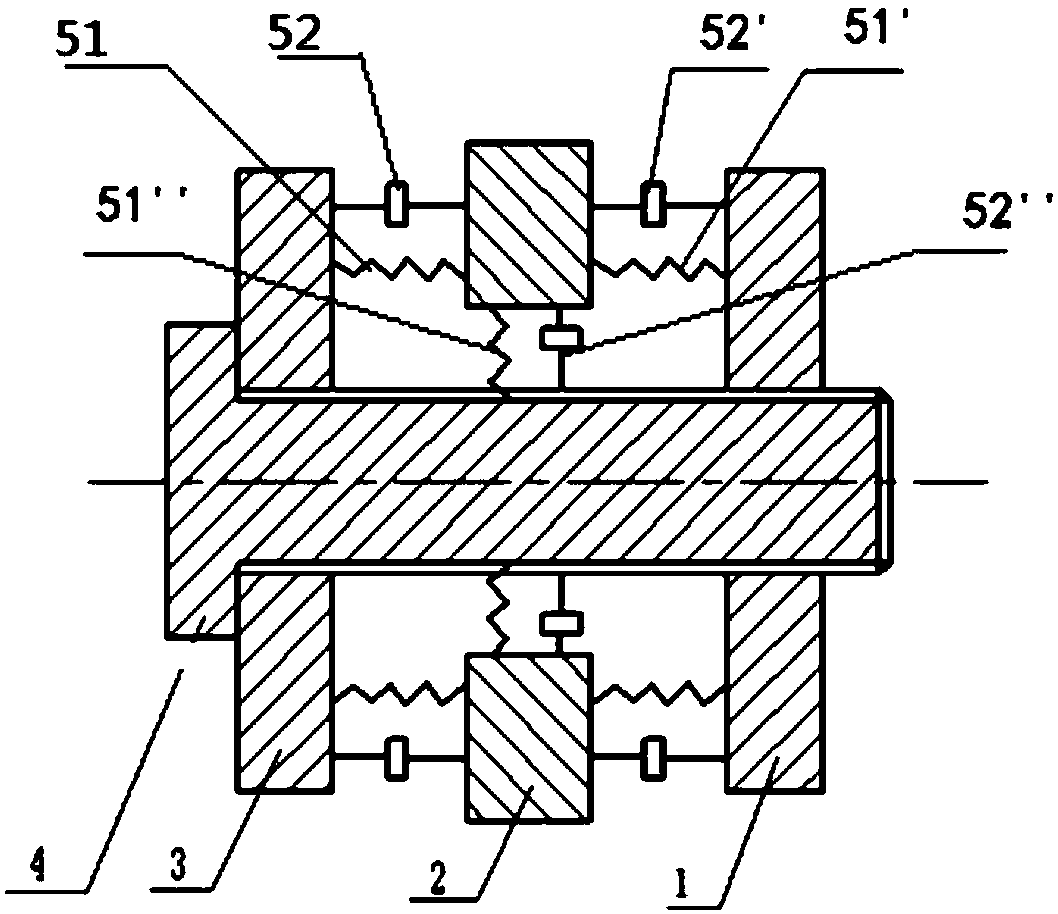

[0045] Please refer to the attached image 3As shown, the top of the middle bolt 4 is fixedly connected to the housing 3 of the electric power mechanism through threaded connection, welding, riveting and other structures, and the bottom end of the middle bolt 4 is connected to the limit locking block through threads, welding, riveting and other structures. 1 fixed connection. One set of elastic structures 51 and one set of damping structures 52 are respectively connected to the casing 3 of the electric power mechanism, and the other end is connected to the first side of the casing 2 of the controller; another set of elastic structures 51' and another One end of the set of damping structures 52' is respectively connected to the second side of the controller housing 2, and the other end is connected to the limit locking block 1; one end of another set of elastic structures 51" and another set of damping structures 52" are respectively connected to The third side of the housing ...

Embodiment 3

[0047] In addition to the same connection as the above-mentioned group of elastic structures 51 and a group of damping structures 52 in the second embodiment, a group of elastic structures 51 and a group of damping structures 52 are also arranged in the Z direction, which are respectively connected to the gear box and the middle bolt. 4. The casing of the controller and the limit locking block 1 are elastically connected to form a vibration-isolation connection in X, Y, and Z directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com