Main driving gear

A main drive and gear technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve the problems of deepening mechanical wear, insufficient mass production and processing, deformation of precision parts, etc. The effect of driving performance, less energy supply, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in combination with specific embodiments.

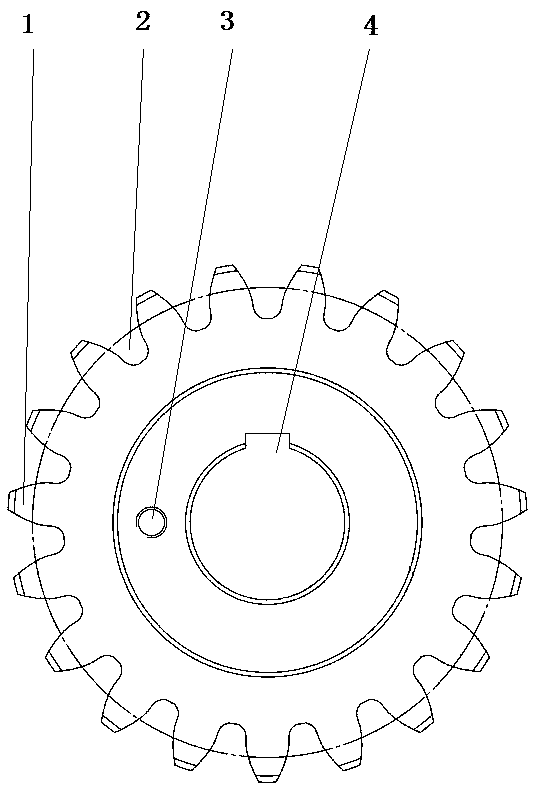

[0018] Such as figure 1 As shown, a main driving gear includes teeth 1, a buffer plastic seal 2, a heat dissipation hole 3 and a central shaft hole 4, the central shaft hole 4 is in a penetrating structure at the center of the main driving gear, and the main driving gear is a ring-closed structure and A cooling hole 3 is provided between the ring structures, and an oil barrel of the same diameter is arranged on the cooling hole 3. The oil leakage hole of the oil barrel is flush with the center line of the central shaft hole 4, and the outer edge of the main driving gear is a tooth 1. Tooth 1 is an overall structure, and the tail end and the top are divided in this sense. The tail end of tooth 1 is an arc-shaped structure, and the top of tooth 1 is a smooth transition section of isosceles trapezoidal structure. A buffer plastic seal 2 is provided at the half tooth, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com