A machine vision-based method for glue offset detection of thermal transfer film

A technology of machine vision and detection methods, which is applied in the direction of instruments, image data processing, calculation, etc., can solve the problems of being easily disturbed by external environment and internal factors, increasing the product processing cost of enterprises, and difficult to form detection standards, etc., to eliminate subjective Differences, increased accuracy, and lower cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with specific embodiment:

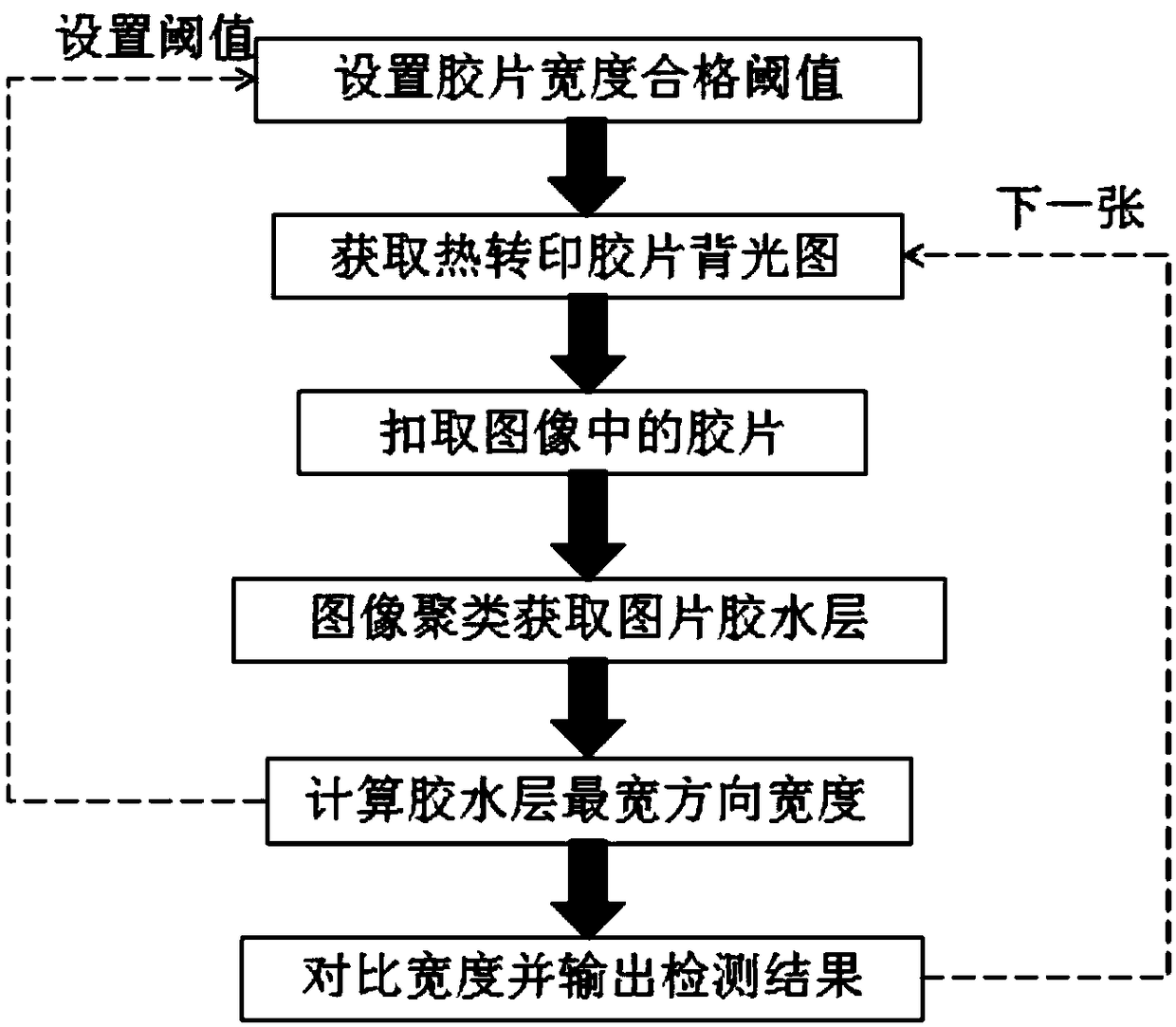

[0067] Such as figure 1 As shown, a machine vision-based method for detecting glue deviation of thermal transfer film described in this embodiment includes the following steps:

[0068] S1: Set the film width qualified threshold:

[0069] The default value of this threshold is 0, which can be modified by using the glue width of the qualified film as a reference after the qualified film is detected;

[0070] S2: Obtain the backlight image of the thermal transfer film:

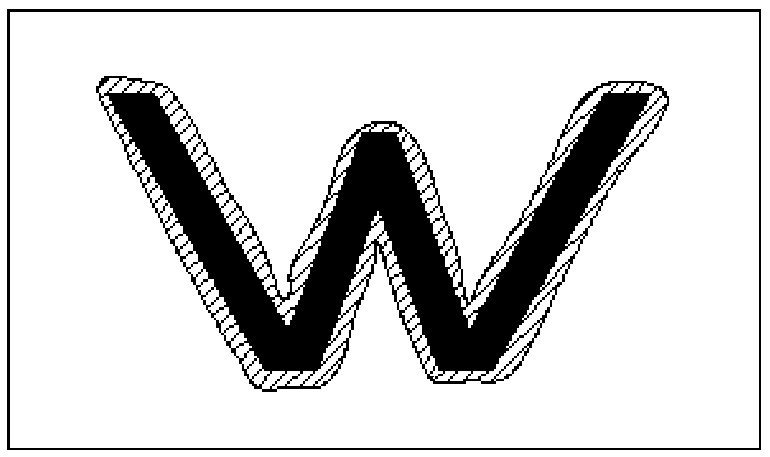

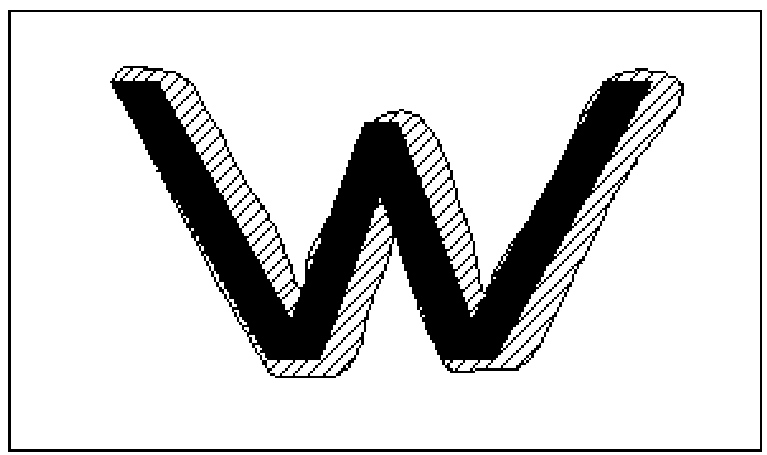

[0071] Place the thermal transfer film on the backlight, and collect the image through the industrial camera. The schematic diagram of the obtained original image is as follows: Figure 4 shown;

[0072] S3: Deduct the film in the image (the thermal transfer film in the original image may be located at any angle and position in the image), the specific process is as follows:

[0073] S3-1: Using the sobe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com