An organic solar cell having a cascaded metal grating structure

A technology of solar cells and metal gratings, applied in the field of solar cells, can solve the problems of cell production cost, efficiency, and service life, which affect the market prospect of the application market, and achieve the effect of broadband absorption enhancement and thickness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

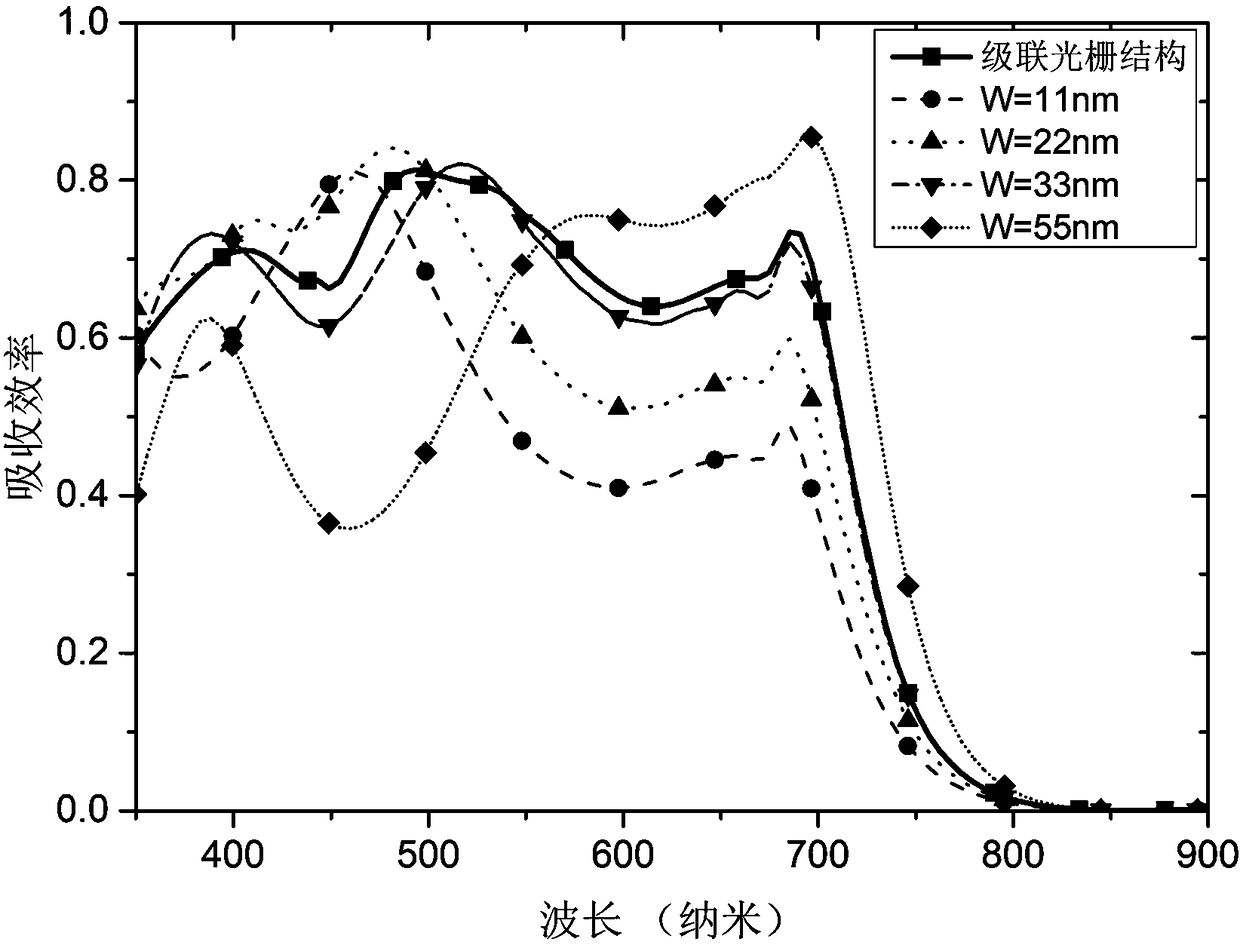

Embodiment 1

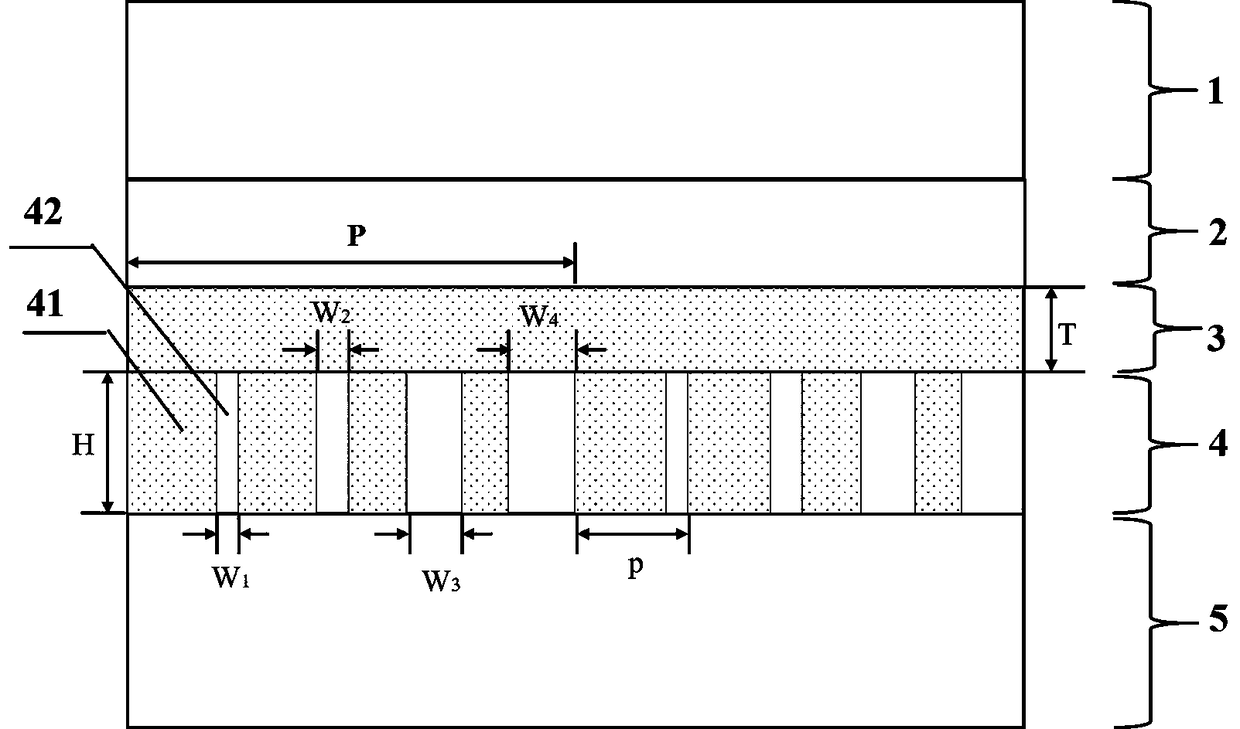

[0023] Such as figure 1 As shown, it is a schematic cross-sectional view of an organic solar cell with a cascaded metal grating structure proposed in this embodiment, which includes a conductive thin film layer 1, a hole transport layer 2, a uniform absorption layer 3, and a grating layer 4 from top to bottom. With the back cathode 5, wherein, the uniform absorption layer 3 and the grating absorption layer, that is, the grating groove 41 are both active layers; the grating layer 4 is a one-dimensional periodic structure formed by a plurality of cascaded gratings with the same structure arranged laterally, each The cascaded grating includes a first grating, a second grating, a third grating and a fourth grating arranged in sequence with equal periods, and the grating ridge width W of the first grating, the second grating, the third grating and the fourth grating is 1 , W 2、 W 3 , W 4 increase in turn, the material of the uniform absorption layer 3 is PTB7:PC mixed in a ratio...

Embodiment 2

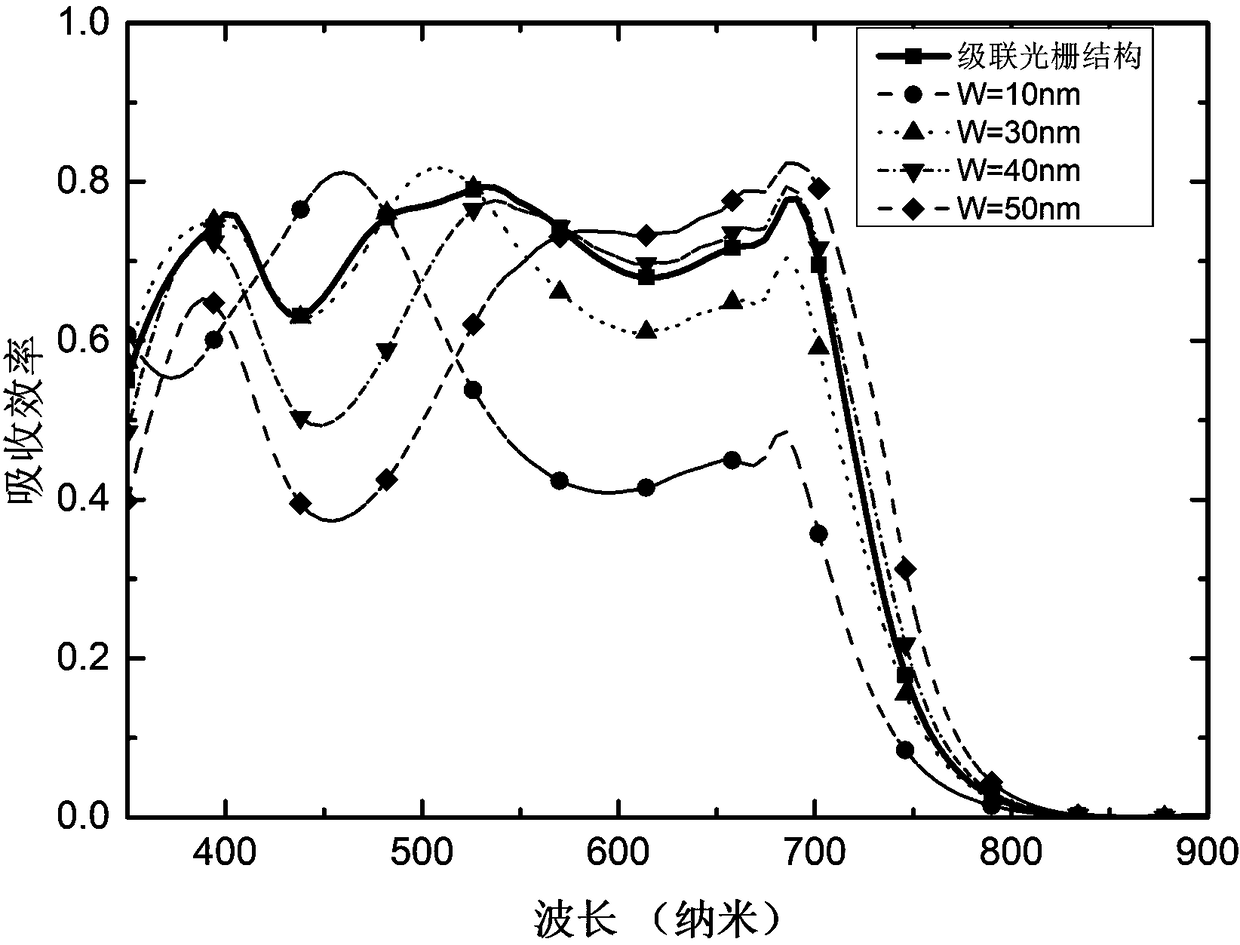

[0029] The structure of an organic solar cell with a cascaded metal grating structure proposed in this embodiment is the same as that of the first embodiment, the difference is that in this embodiment, the thickness T of the uniform absorption layer 3 and the thickness H of the grating layer 4 are respectively are 10nm and 40nm, the period P of the cascaded metal grating structure is 400nm, and the period p of each grating is 100nm. In addition, the grating ridge width W of the first grating, the second grating, the third grating, and the fourth grating 1 , W 2、 W 3 , W 4 They are 10 nanometers, 30 nanometers, 40 nanometers, and 50 nanometers.

[0030] Such as image 3 Shown is the spectral line diagram of the absorption efficiencies of the cascaded metal grating solar cells and the four non-cascaded metal grating solar cells of this embodiment. The structures of these four non-cascaded metal grating solar cells are basically the same as in this embodiment, and they all i...

Embodiment 3

[0033] The structure of an organic solar cell with a cascaded metal grating structure proposed in this embodiment is the same as that of the first embodiment and the second embodiment, the difference is that in this embodiment, the thickness T of the uniform absorption layer 3 and the grating layer The thickness H of 4 is 10 nanometers and 40 nanometers respectively, the period P of the cascaded metal grating structure is 480nm, and the period p of each grating is 120nm. In addition, the grating ridge width W of the first grating, the second grating, the third grating, and the fourth grating 1 , W 2、 W 3 , W 4 They are 12nm, 24nm, 36nm and 60nm respectively. In this embodiment, the average absorption efficiency of the solar cell with this structure can reach 47.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com