Flue gas treatment device for rubber processing

A flue gas treatment and rubber technology, applied in the direction of gas treatment, liquid separation agent, membrane technology, etc., can solve the problems of secondary pollution and high cost, and achieve a thorough treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

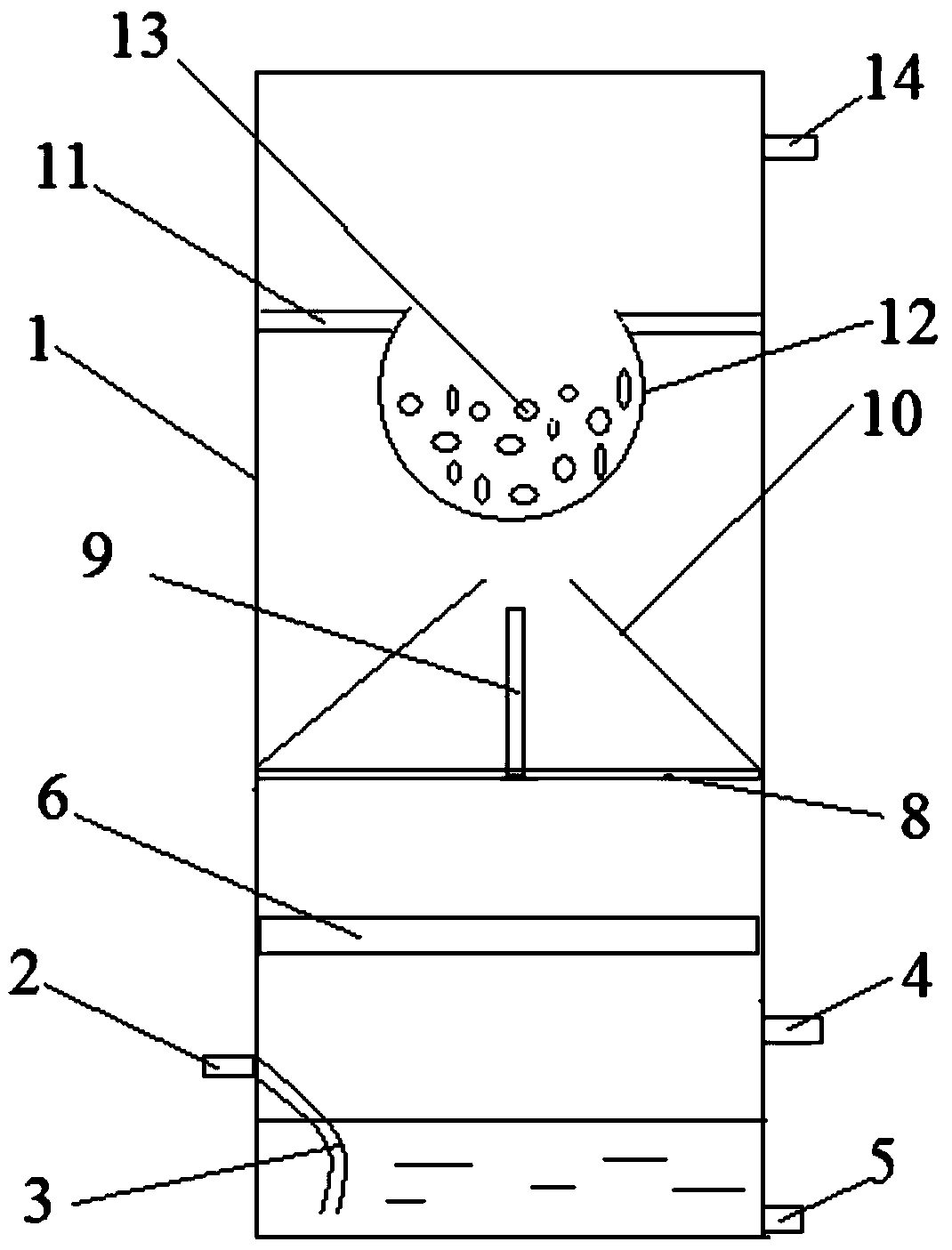

[0013] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0014] Such as figure 1 As shown, a flue gas treatment device for rubber processing is characterized in that it includes a cylinder body 1, the upper and lower parts of the side wall of the cylinder body 1 are respectively provided with a waste gas outlet 14 and a waste gas inlet 2, and the inner bottom of the cylinder body 1 There is a treatment liquid on the top, the exhaust gas inlet 2 is connected to one end of the air guide pipe 3, the other end of the air guide pipe 3 is inserted below the liquid level of the treatment liquid, and the side wall of the cylinder 1 is provided with a water inlet 4 and a water outlet 5, the cylinder In the body 1, a drying net 6 is arranged above the water inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap