A continuous casting billet with optimized surface quality and its manufacturing method

A manufacturing method and surface quality technology, applied in the field of metal processing, can solve problems such as dents and longitudinal cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

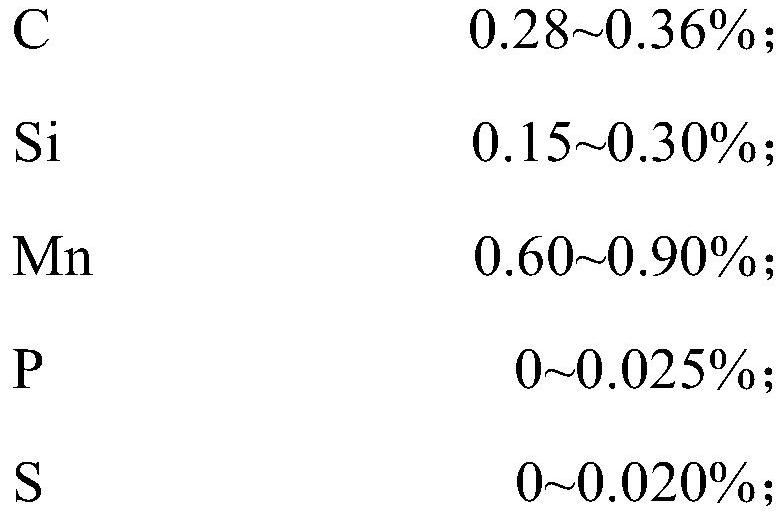

[0021] This embodiment provides a continuously cast billet with optimized surface quality. The continuous casting billet is composed of the following elements by weight percentage:

[0022]

[0023] The balance is Fe and unavoidable impurities.

[0024] The cross-sectional size of the continuous casting billet is 270mm×315mm, and its manufacturing method is as follows:

[0025] The molten steel containing the elements in the above weight percentage is injected into the tundish through the ladle long nozzle, and then the molten steel in the tundish flows into the crystallizer through the submerged nozzle, and the distance between the submerged nozzle and the outer arc side of the crystallizer is Distance - the distance between the submerged nozzle and the inner arc side of the mold = 2mm, the specific water volume of the secondary cooling for continuous casting is 0.27L / kg, and the casting speed of the continuous casting slab is 0.6m / min.

[0026] The surface quality of th...

Embodiment 2

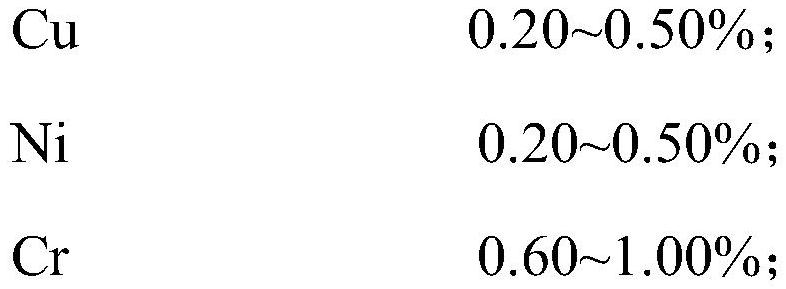

[0028] This embodiment provides a continuously cast billet with optimized surface quality. The continuous casting billet is composed of the following elements by weight percentage:

[0029]

[0030]

[0031] The balance is Fe and unavoidable impurities.

[0032] The cross-sectional size of the continuous casting billet is 280mm×325mm, and its manufacturing method is as follows:

[0033] The molten steel containing the elements in the above weight percentage is injected into the tundish through the ladle long nozzle, and then the molten steel in the tundish flows into the crystallizer through the submerged nozzle, and the distance between the submerged nozzle and the outer arc side of the crystallizer is Distance - the distance between the submerged nozzle and the inner arc side of the mold = 4mm, the specific water volume of the secondary cooling for continuous casting is 0.30L / kg, and the casting speed of the continuous casting slab is 0.65m / min.

[0034] The surface ...

Embodiment 3

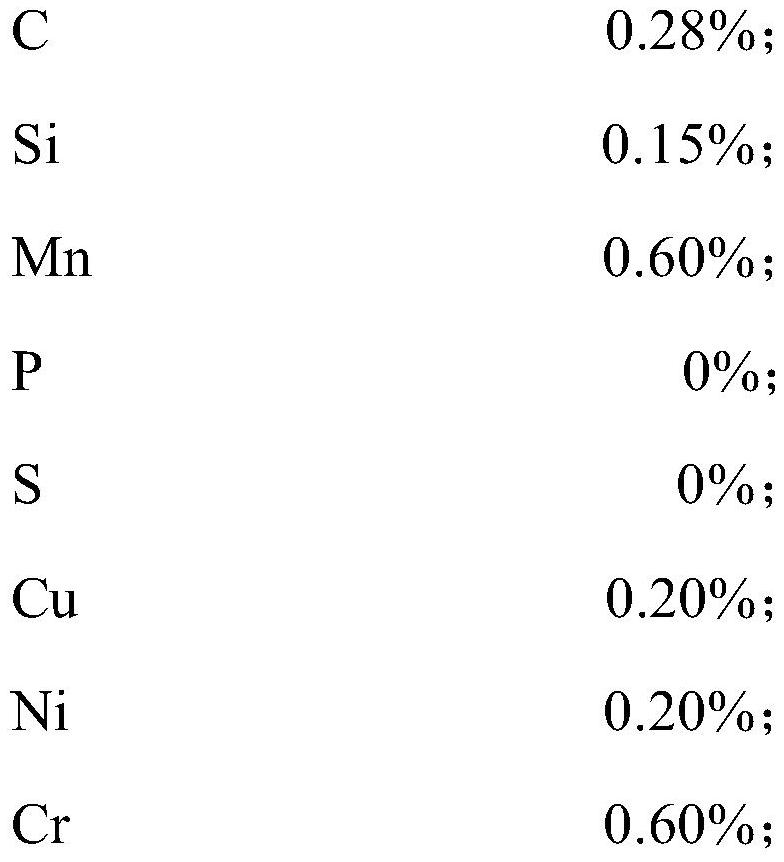

[0036] This embodiment provides a continuously cast billet with optimized surface quality. The continuous casting billet is composed of the following elements by weight percentage:

[0037]

[0038] The balance is Fe and unavoidable impurities.

[0039] The cross-sectional size of the continuous casting billet is 290mm×335mm, and its manufacturing method is as follows:

[0040] The molten steel containing the elements in the above weight percentage is injected into the tundish through the ladle long nozzle, and then the molten steel in the tundish flows into the crystallizer through the submerged nozzle, and the distance between the submerged nozzle and the outer arc side of the crystallizer is Distance - the distance between the submerged nozzle and the inner arc side of the mold = 6mm, the specific water volume of the secondary cooling for continuous casting is 0.35L / kg, and the casting speed of the continuous casting slab is 0.73m / min.

[0041] The surface quality of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com