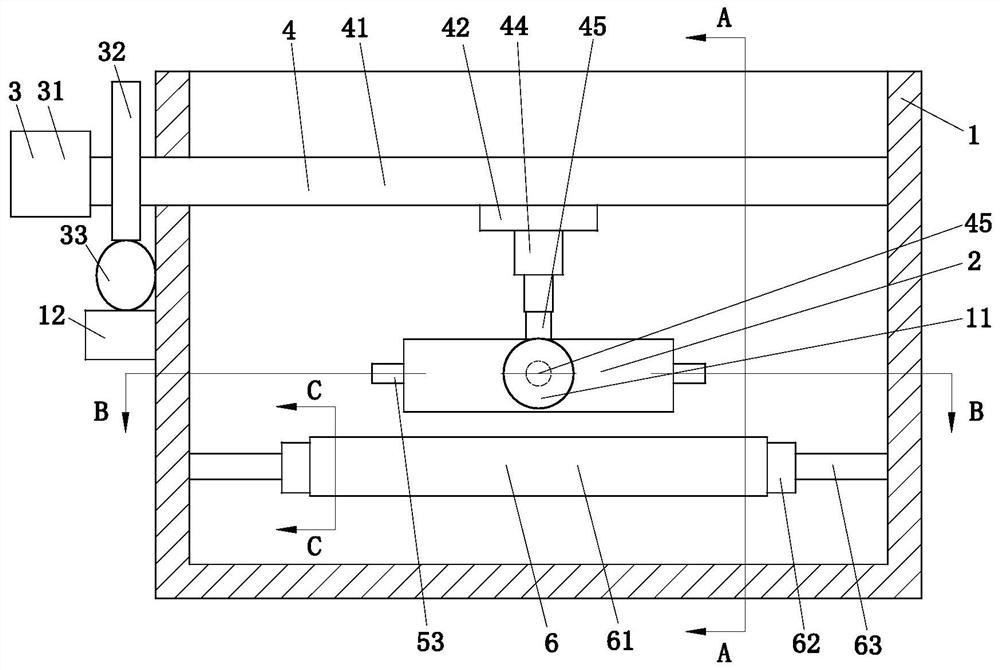

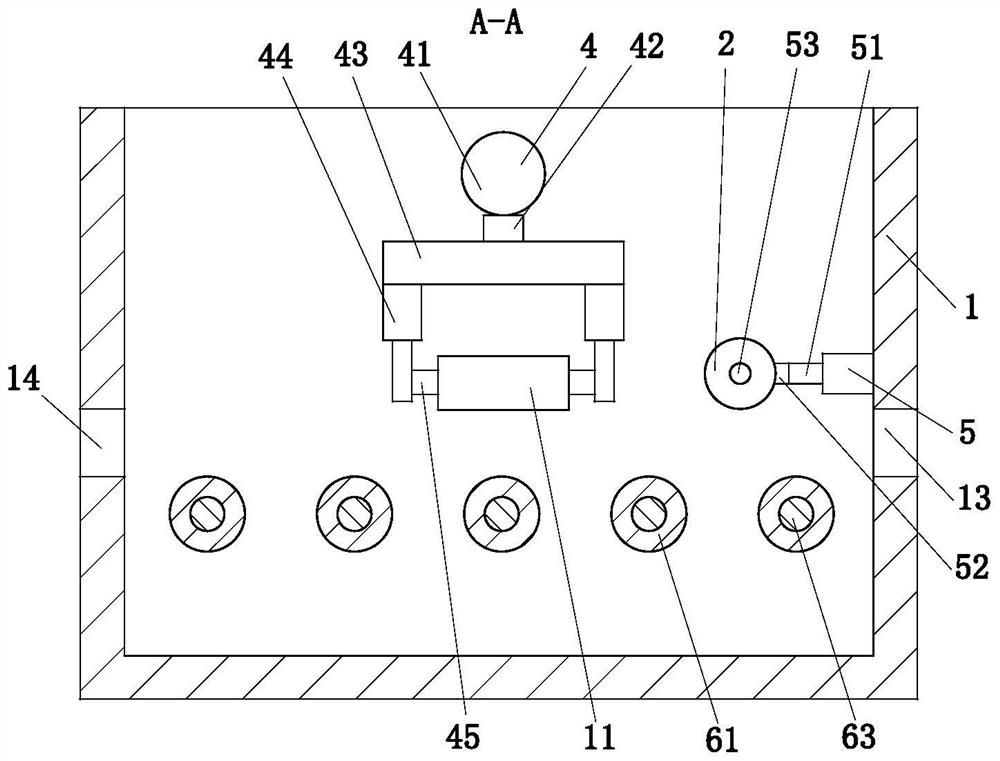

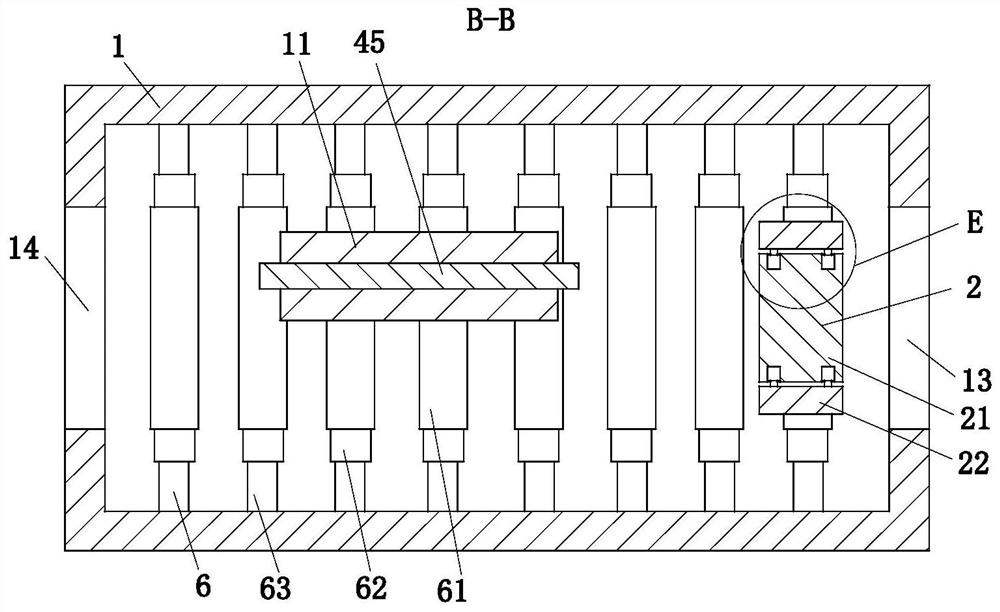

A plywood pressing molding machine

A synthetic molding machine and plywood technology, which is applied in the jointing of wooden veneers, manufacturing tools, wood processing equipment, etc., can solve the problems of plywood rolling, affecting the effect of plywood pressing, and uneven distribution of plywood glue, so as to improve the pressing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] As an embodiment of the present invention, the rotating rod 72 is composed of a No. 1 rod 721 and a No. 2 rod 722; one end of the No. 1 rod 721 is circular, and one end of the No. 1 rod 721 is in contact with the No. 4 shaft 74, The other end of the No. 1 rod 721 is hinged to the No. 2 rod 722. A torsion spring is provided at the hinge so that the No. 1 rod 721 can pass over the protrusion 71; the end of the No. 2 rod 722 away from the No. 1 rod 721 is arc-shaped. Generally, the rotating rod 72 is a long rod, and there are deficiencies in the design of the long rod. On the one hand, the long rod is easy to break and has poor flexibility, thereby affecting the pressing efficiency of the plywood; on the other hand, the rotating rod 72 is rotating. The rod 72 exerts a large force on the second shaft 63, which easily causes damage to the second shaft 63, thus affecting the service life of the second shaft 63; the present invention consists of a first rod 721 and a second rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com