A mechanical billet assembly device for side-pressed bamboo glulam laminates

A technology of laminated wood and mechanical group, which is used in the joining of wooden veneers, wood processing appliances, manufacturing tools, etc., can solve the problems of poor working environment, low work efficiency, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

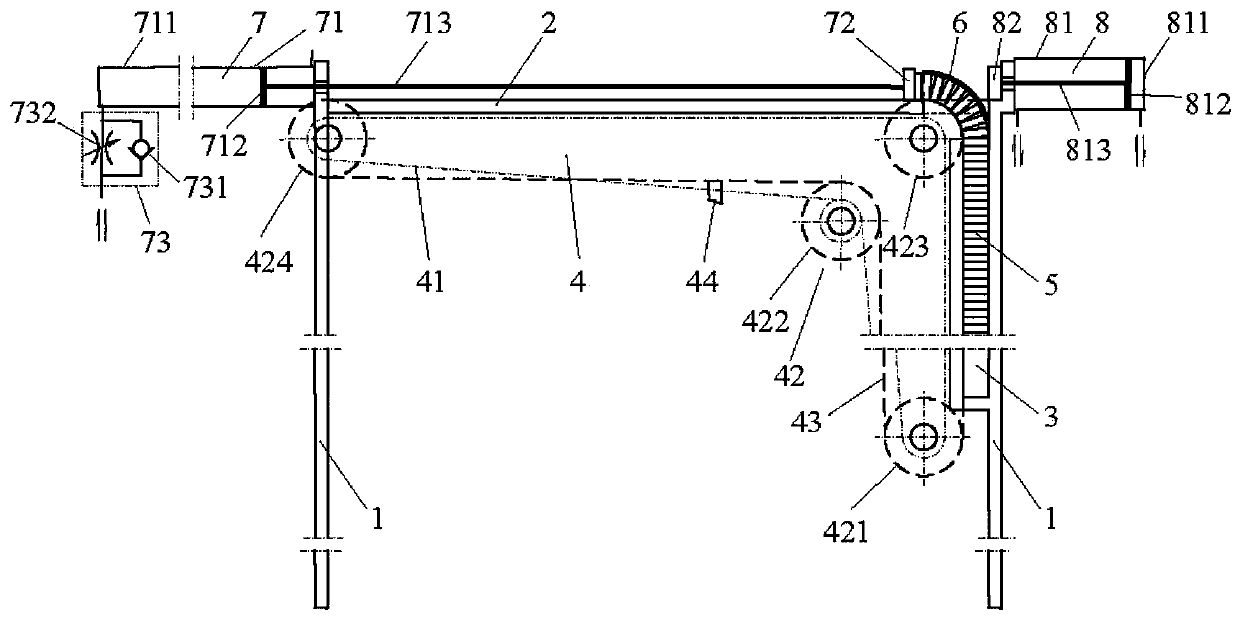

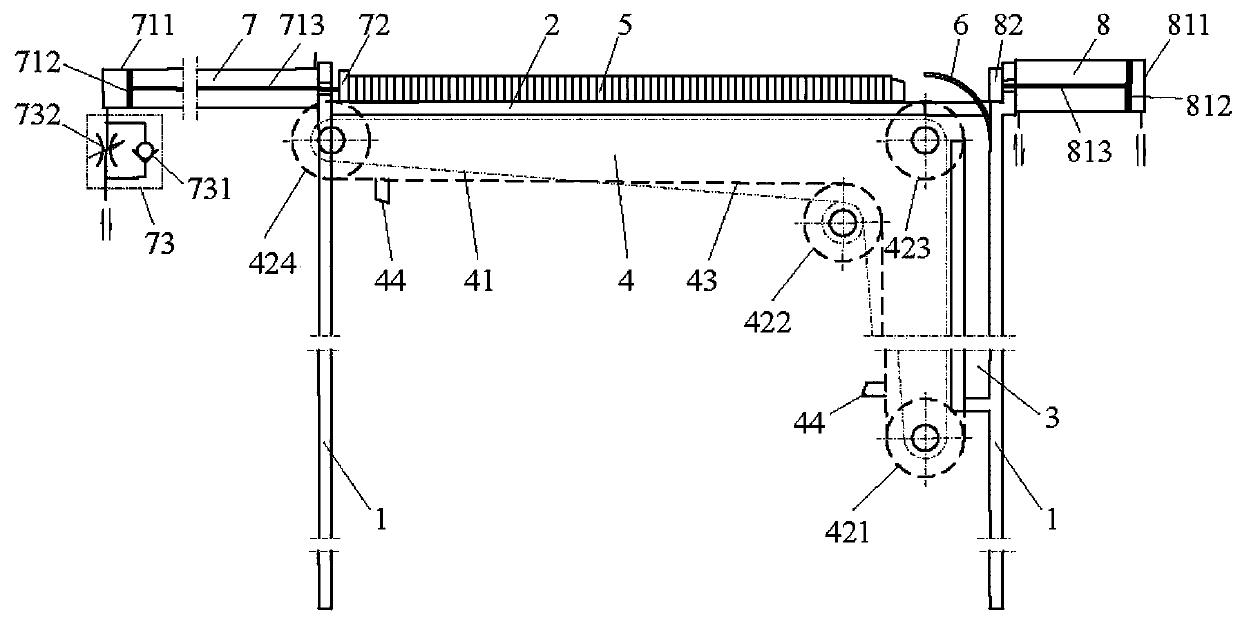

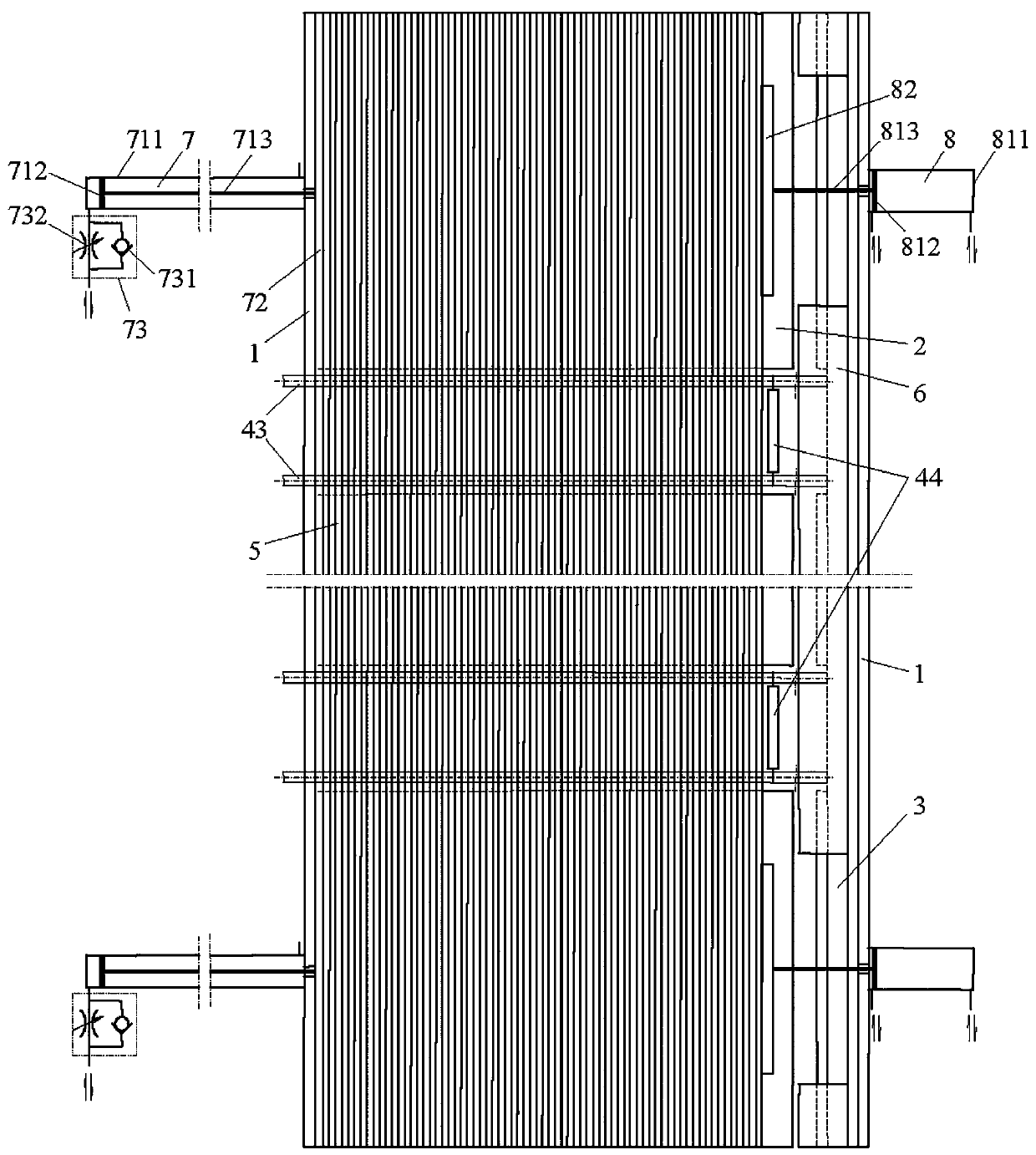

Embodiment 1

[0026] Slab size is 2500mm (long) * 1248mm (wide) * 20mm (thick), and the specification of strip bamboo chip 5 is 2500mm (long) * 20mm (wide) * 6mm (thick), and the size of workbench 2 is 2540mm ( length) * 1350mm (width), the effective working stroke of the first cylinder 71 is 1400mm, and the effective working stroke of the second cylinder 81 is 200mm. First adjust the throttle opening of the one-way throttle valve 73 to an appropriate size, so that there is a certain resistance when the bamboo sheet baffle plate 72 is returned; Sheet baffle plate 72 moves rightward to the far right of workbench 2; Chain delivery mechanism 4 rises, and the upper surface height of chain 43 is concordant with workbench 2; Groove 3, and be stacked to height after being 1248mm (208 pieces of bamboo slices), the driving wheel 421 action of chain delivery mechanism 4, chain 43 operation is made, drives hanging plate 44 to promote the elongated bamboo slice 5 in the vertical material trough 3; Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com