Automatic distributing device for O-shaped sealing ring vulcanized formed blank, and distributing method thereof

A technology of O-shaped sealing ring and automatic material distribution, applied in the direction of conveyor control device, transportation and packaging, conveyor objects, etc., can solve the problems of low production efficiency, low degree of automation, automatic docking, etc., to achieve effective discharge and reduce Labor intensity, fast cloth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

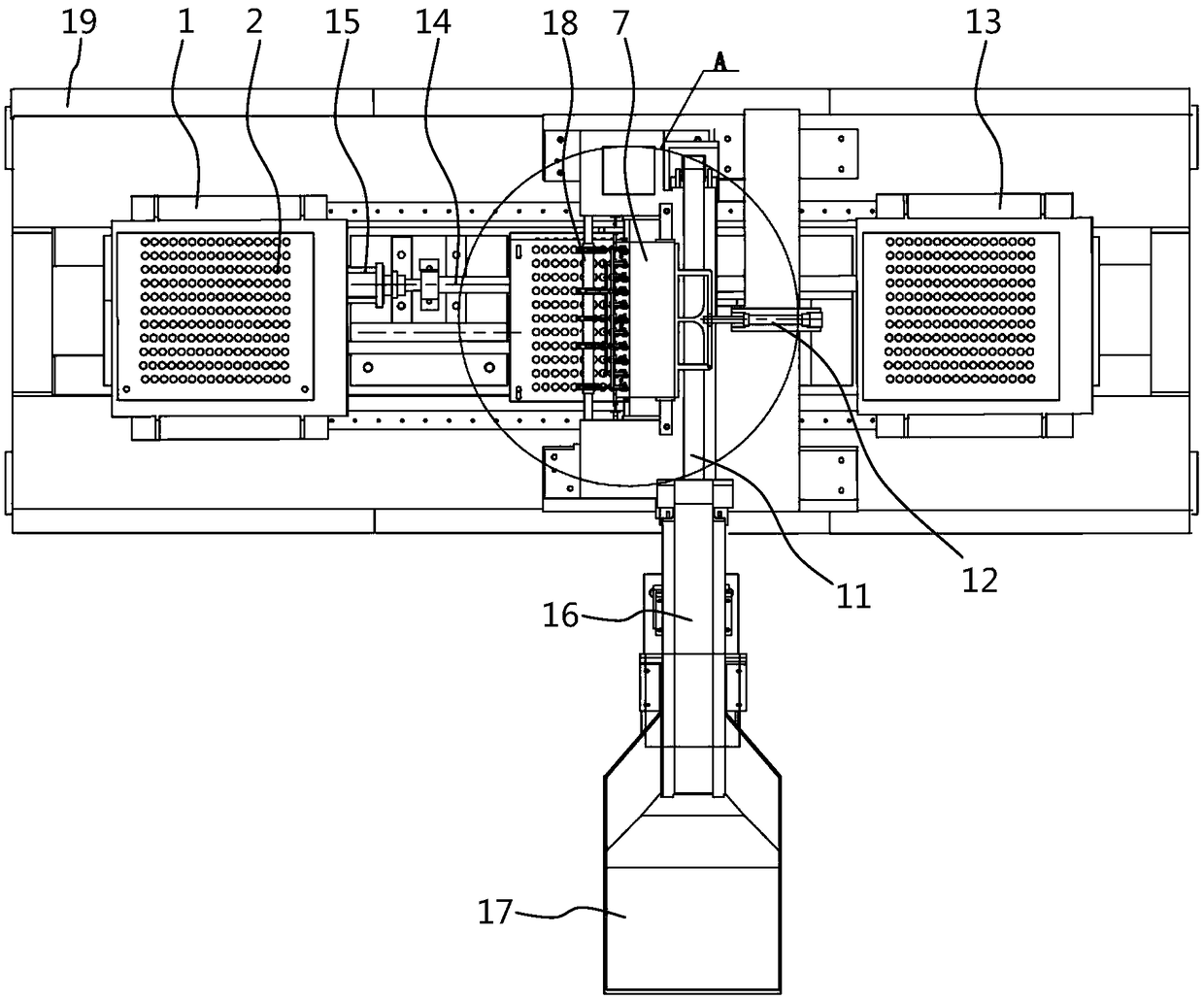

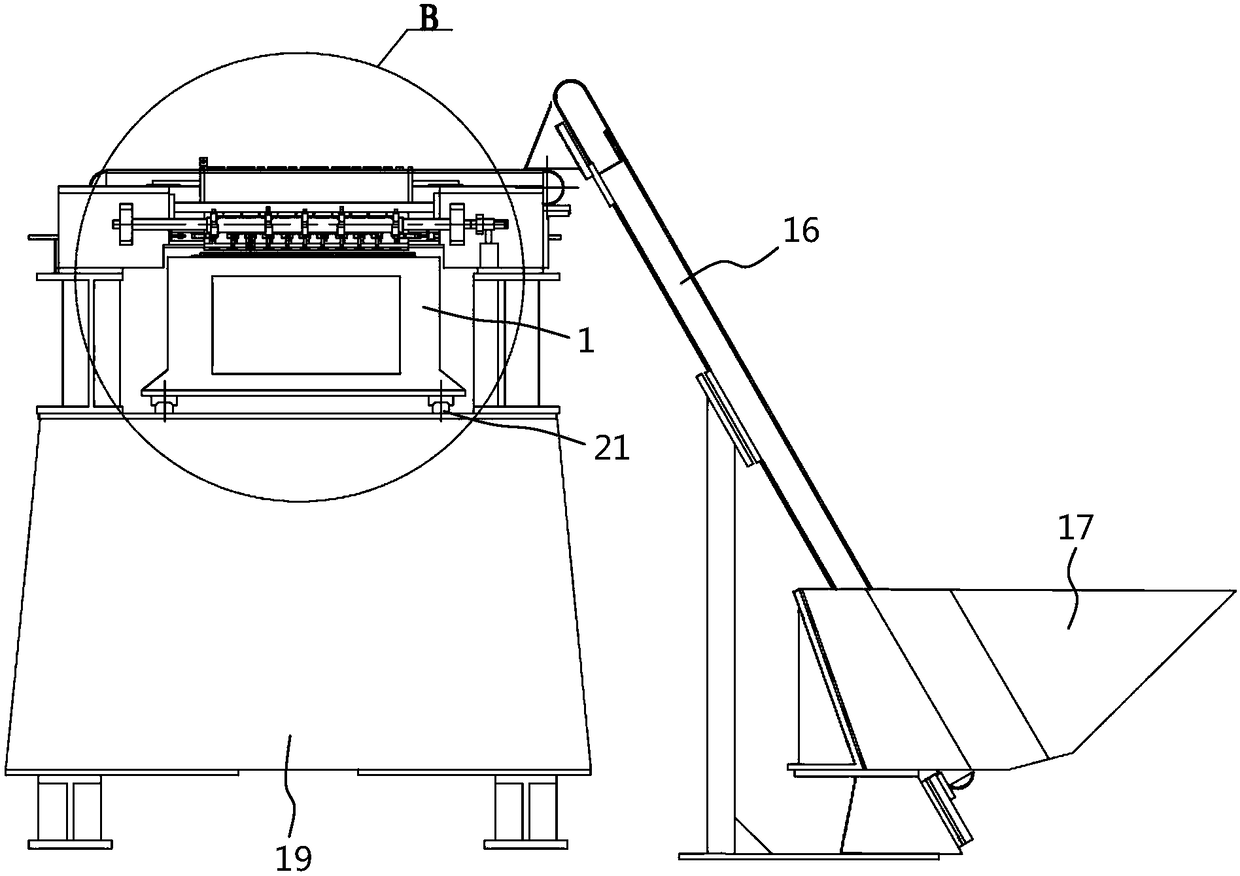

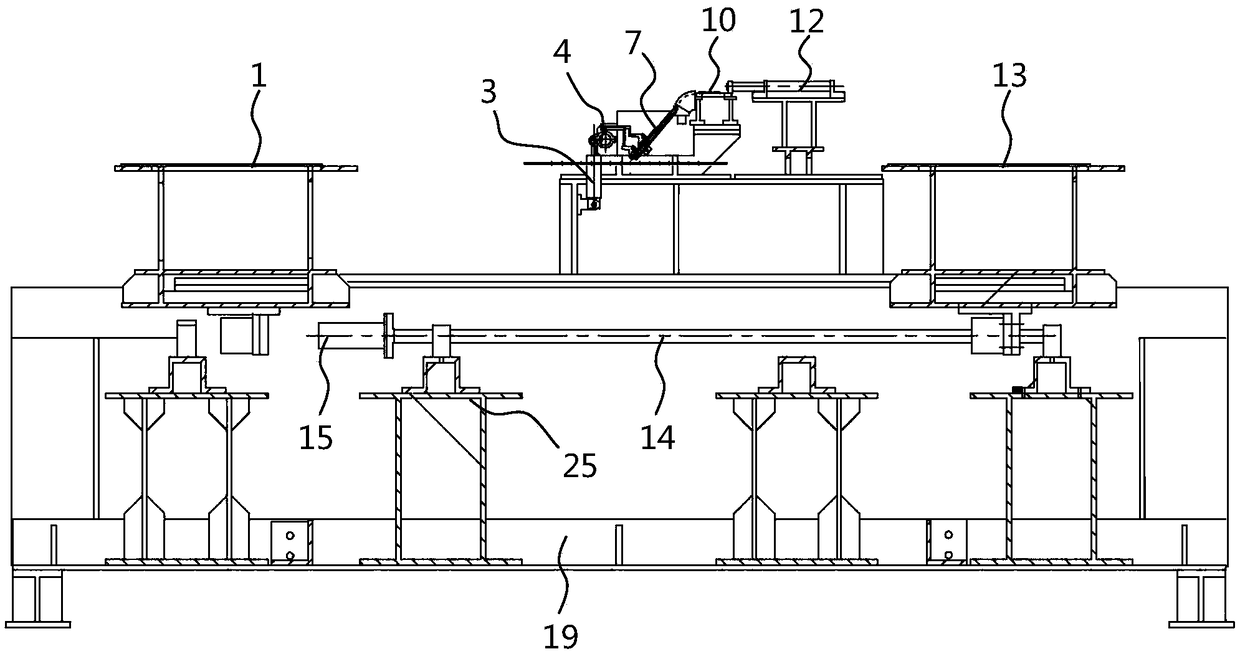

[0047] Such as Figure 1 to Figure 7 The shown automatic distribution device for an O-ring vulcanization forming blank of the present invention includes: a base 19, on which two guide rails 21 and several fixing seats are arranged in parallel, and the two guide rails 21 are horizontally installed on the base 19 On the end face, the number of fixing seats is four and arranged symmetrically in pairs;

[0048] Wherein: conveying mechanism, it has the first carrying frame 1 that cooperates with guide rail 21 and the second carrying frame 13 and the drive motor 15 that is arranged on the fixed base and the screw mandrel 14 that is connected with drive motor 15, screw mandrel 14 and the first Carrying frame 1 and the second carrying frame 13 are connected; Screw mandrel 14 drives the first carrying frame 1 and the second carrying frame 13 to move left and right, wherein the first carrying frame 1 and the second carrying frame 13 are respectively placed with movable tray 2, with To ...

Embodiment 2

[0056] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 6 As shown, the cloth mechanism also has at least one position detection switch 20, the position detection switch 20 is electrically connected to the PLC controller, and is arranged on at least one side of the belt conveyor 11 through a bracket 22, and the position detection switch 20 is used to detect whether the blank 10 has When the position set by the pusher 12 is reached, the position detection switch 20 can be a limit switch currently used in the market.

Embodiment 3

[0058] The structure of this embodiment is basically the same as that of Embodiment 2, the difference is that: Figure 4 and Figure 7 As shown, in the actual use process, the offside of the blank 10 is likely to cause the material blocking problem of the material distribution funnel 7. The material distribution mechanism also has at least one photoelectric switch 8, which is electrically connected to the PLC controller and is arranged on the material distribution funnel. The feeding end of 7 effectively prevents the billet 10 from being brought to the non-working area by the belt conveyor 11, and at the same time solves the problem of material blocking. Photoelectric switch 8 is the photoelectric switch that market uses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com