A kind of p-n-si synergistic flame retardant epoxy resin curing agent and preparation method thereof

An epoxy resin curing and synergistic flame retardant technology, which is applied in chemical instruments and methods, organic chemistry, compounds of group 5/15 elements of the periodic table, etc., can solve problems such as fire hazards and restrictions, and achieve the goal of not being easy to migrate and penetrate The effect of low output, low performance and excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

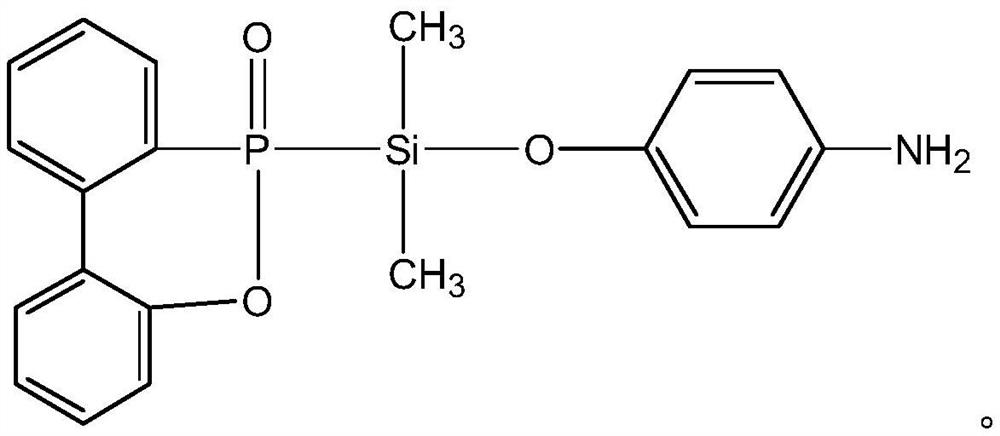

[0031] A novel P-N-Si synergistic flame retardant epoxy resin curing agent, its molecular structure is as follows:

[0032]

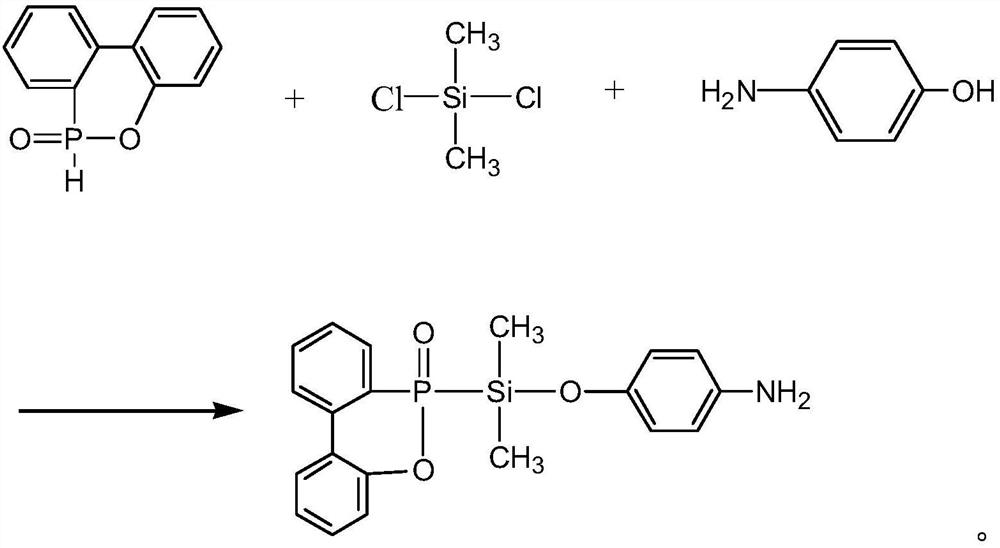

[0033] Above-mentioned compound synthesis method, the steps are as follows:

[0034] 1. Under an inert gas atmosphere, add p-aminophenol and dioxane to a device equipped with a dropping funnel, agitator, and condensation reflux. After the p-aminophenol is completely dissolved, add dichlorodimethylsilane dropwise , Reacted at 80°C for 10h to obtain an intermediate product.

[0035] 2. Under an inert gas atmosphere, mix the intermediate product, DOPO and N’N-dimethylformamide, and react at 140°C for 16 hours. After the reaction is completed, the final product is obtained after cooling, suction filtration, and recrystallization.

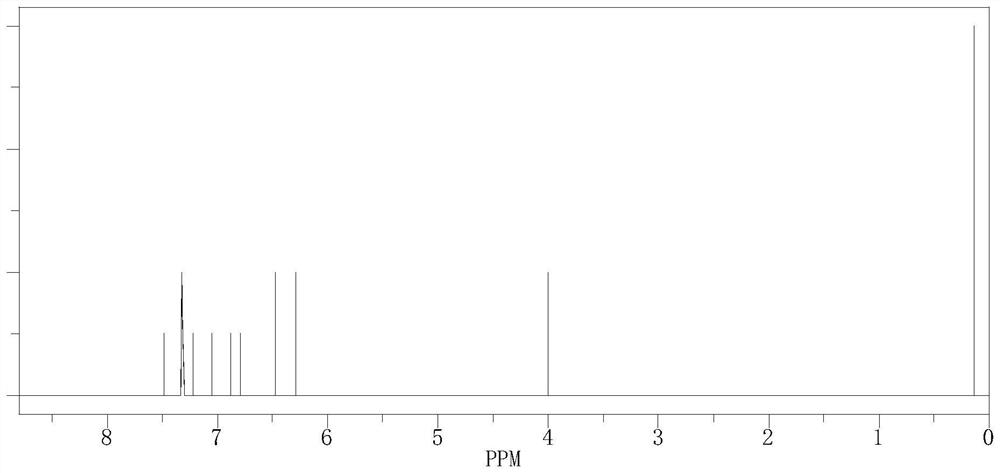

[0036] figure 1 For the novel P-N-Si synergy flame-retardant epoxy resin curing agent prepared by example 1 of the present invention 1 H-NMR spectrum. The analysis is shown in Table 1, and the formation of the product can ...

Embodiment 2

[0040] A novel P-N-Si synergistic flame retardant epoxy resin curing agent, its synthetic method is as follows:

[0041] 1. Under an inert gas atmosphere, add p-aminophenol and dioxane to a device equipped with a dropping funnel, agitator, and condensation reflux. After the p-aminophenol is completely dissolved, add dichlorodimethylsilane dropwise , reacted at 90°C for 9h, after the reaction was completed, an intermediate product was obtained.

[0042] 2. Under an inert gas atmosphere, mix the intermediate product, DOPO and N’N-dimethylformamide, and react at 130°C for 16 hours. After the reaction is completed, the final product is obtained after cooling, suction filtration, and recrystallization.

Embodiment 3

[0044] A novel P-N-Si synergistic flame retardant epoxy resin curing agent, its synthetic method is as follows:

[0045] 1. Under an inert gas atmosphere, add p-aminophenol and dioxane to a device equipped with a dropping funnel, agitator, and condensation reflux. After the p-aminophenol is completely dissolved, add dichlorodimethylsilane dropwise , Reacted at 100°C for 8h to obtain an intermediate product.

[0046] 2. Under an inert gas atmosphere, mix the intermediate product, DOPO and N’N-dimethylformamide, and react at 140°C for 18 hours. After the reaction, the final product is obtained after cooling, suction filtration, and recrystallization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com