Phosphorus-containing water-soluble flame retardant and preparation method thereof

A flame retardant, water-soluble technology, applied in the field of water-soluble flame retardants and their preparation, can solve the problems of affecting the stress transfer between the interface and the units on both sides, the large amount of additive flame retardants, poor mechanical properties and durability, etc. Achieve the effect of avoiding the problem of migration and precipitation, simple preparation method and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

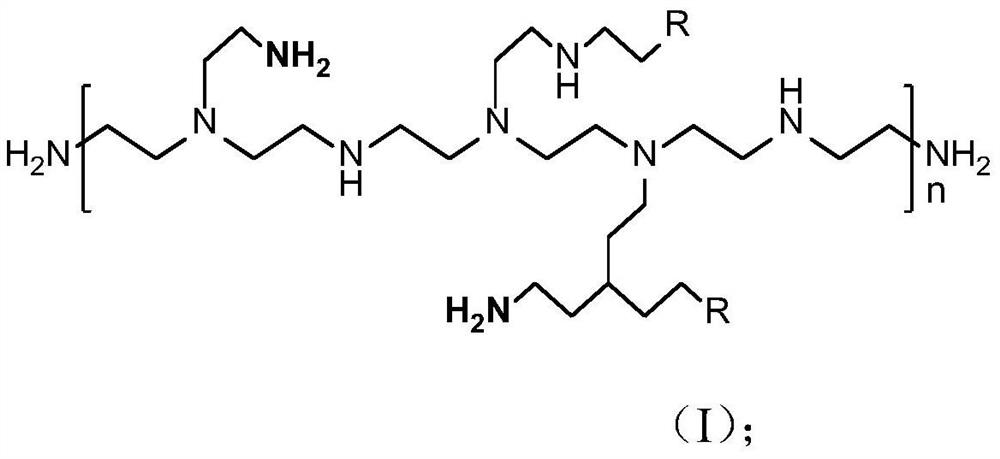

[0052] Another aspect of the embodiments of the present invention provides a method for preparing a phosphorus-containing water-soluble flame retardant, which includes:

[0053] Polyethyleneimine (PEI) shown in the general formula (II) structure, the monovalent aldehyde compound shown in the general formula (III) structure and the phosphoric acid ester compound shown in the general formula (IV) structure are mixed and reacted to prepare Obtain described water-soluble flame retardant, described compound has general formula (I) structure:

[0054] in:

[0055]

[0056] in:

[0057] R 1 selected from hydrogen, substituted or unsubstituted C 1 -C 20 Alkyl, substituted or unsubstituted C 2 -C 20 Alkenyl, substituted or unsubstituted C 6 -C 20 Aryl, substituted or unsubstituted C 2 -C 20 Heteroaryl, substituted or unsubstituted C 4 -C 20 Carbocyclyl, substituted or unsubstituted C 2 -C 20 Heterocyclyl, or C 3 -C 8 Cycloalkyl;

[0058] R 2 selected from

[0...

Embodiment 1

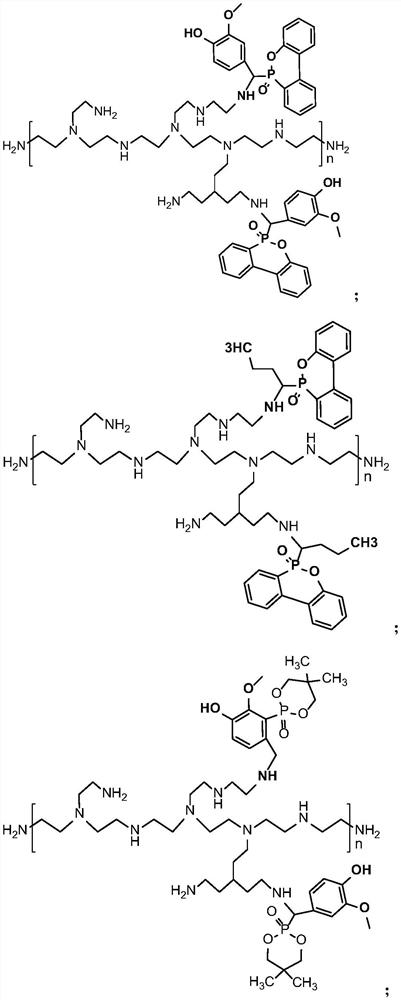

[0090] (1) Preparation of water-soluble flame retardant: 100 molar parts of polyethyleneimine, 26 molar parts of vanillin, 26 molar parts of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxidized The mixture of dopo (DOPO) was dissolved in methanol, and the system was reacted at 120°C for 12 hours to obtain a water-soluble flame retardant (FR-1), whose structural formula is as follows:

[0091]

[0092] After testing, the proton nuclear magnetic resonance spectrum is as follows:

[0093] 1 H NMR (500MHz, Methanol-d 4 )δ7.99(d, J=6.6Hz, 1H), 7.67(s, 1H), 7.49 (d, J=0.9Hz, 1H), 7.38(s, 1H), 6.96(d, J=0.8Hz, 1H), 3.82(s,3H), 3.05(s,1H), 2.88–2.59(m,19H), 1.74–1.64(m,2H), 1.44(s,1H), indicating that FR-1 was synthesized.

[0094] (2) Preparation of flame-retardant plant fiber reinforced epoxy resin composite material: 12 parts by mass of FR-1 was dissolved in water to prepare a flame retardant solution, and 100 parts by mass of ramie fabric was soaked in the flame retardant a...

Embodiment 2

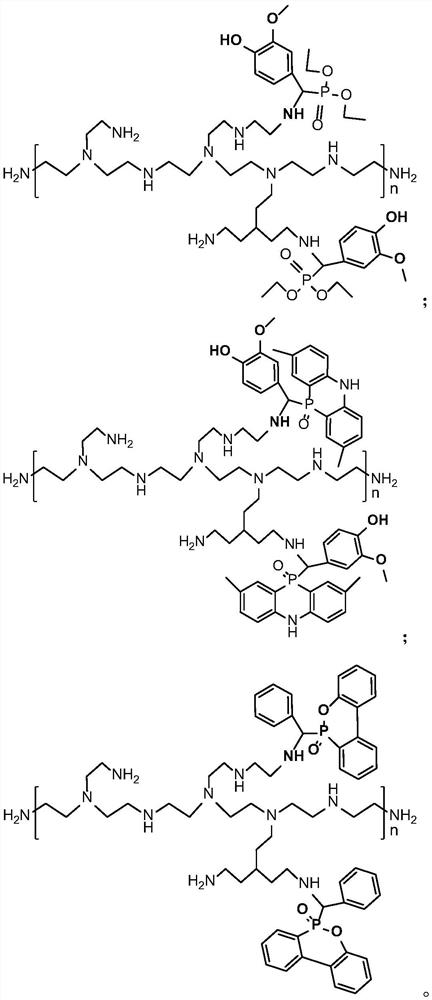

[0099] (1) Preparation of water-soluble flame retardant: 100 molar parts of polyethyleneimine, 20 molar parts of n-butyraldehyde, 20 molar parts of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10- A mixture of oxides (DOPO) was dissolved in ethanol, and the system was reacted at 100°C for 8 hours to obtain a water-soluble flame retardant (FR-2), whose structural formula is as follows:

[0100]

[0101] After testing, the proton nuclear magnetic resonance spectrum is as follows:

[0102] 1 H NMR (500MHz, Methanol-d 4 )δ8.02–7.97(m,2H),7.93(s,1H),7.59(s,1H),7.49(d,J=0.8Hz,2H),7.38(d,J=2.0Hz,2H), 3.77(d,J=6.0Hz,1H),3.71(d,J=10.0Hz,1H),3.11(s,0H),3.05(s,1H),2.96(s,1H),2.86(s,1H ),2.83–2.74 (m,7H),2.75(dd,J=2.6,1.3Hz,3H),2.74–2.69(m,6H),2.72–2.63(m,7H),2.65–2.59(m,3H ), 2.51(d, J=2.3Hz, 1H), 1.84(d, J=7.4Hz, 2H), 1.76(d, J=5.1Hz, 2H), 1.71–1.64(m, 3H), 1.44(d , J=0.7Hz, 1H), 1.38(d, J=9.4Hz, 2H), 0.93(s, 4H), indicating that FR-2 was synthesized.

[0103] (2) Preparation of f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interlaminar shear strength | aaaaa | aaaaa |

| Interlaminar shear strength | aaaaa | aaaaa |

| Interlaminar shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com