Mixed hydrophilic polyisocyanate curing agent

A polyisocyanate and curing agent technology, applied in the field of water-based polymer synthesis, can solve the problems of high cost, difficult condition control, complicated process, etc., and achieve the effects of less side reactions, simple operation and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 60.0g of hexamethylene diisocyanate trimer to the three-necked flask, and pass nitrogen; add 9.0g of polyethylene glycol monomethyl ether with a functionality of 0.998, and then raise the temperature to 75°C to allow the contents of the container to fully react for 5 hour; then lower the temperature to 10°C, then slowly add 1.2g of sodium ethylenediaminoethanesulfonate, and continue the reaction for 20 minutes; finally, after reaching room temperature, stop feeding nitrogen, take out to obtain a mixed hydrophilic polyisocyanate solidified agent.

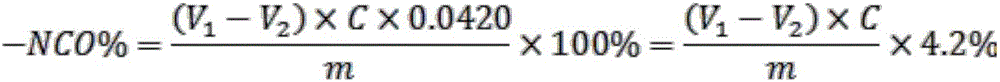

[0029] The -NCO content of the obtained mixed hydrophilic polyisocyanate curing agent was calculated to be 15.9%; its viscosity was measured to be 47.1 mPa·s; and its average particle size was measured to be 277.7 nm.

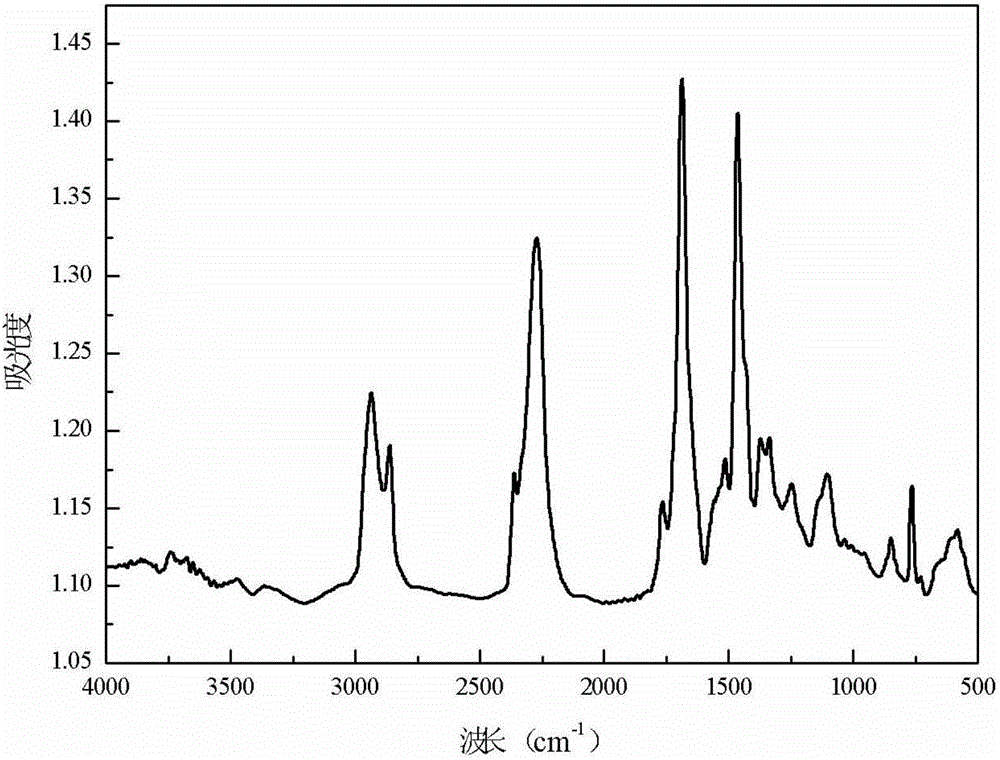

[0030] Infrared test is carried out to the mixed hydrophilic polyisocyanate curing agent obtained, figure 1 Its infrared spectrum, 2273cm -1 At -NCO, 1106cm -1 The ether bond absorption peak at , where -...

Embodiment 2

[0032] Add 70.0g of hexamethylene diisocyanate trimer to the three-necked flask, and pass nitrogen; add 3.5g of polyethylene glycol monomethyl ether with a functionality of 0.997, and then raise the temperature to 70°C to allow the contents of the container to fully react for 5 hours; then lower the temperature to 0°C, then slowly add 1.4g of sodium ethylenediaminoethanesulfonate, and continue the reaction for 30 minutes; finally, after reaching room temperature, stop feeding nitrogen, take out to obtain a mixed hydrophilic polyisocyanate solidified agent.

[0033] The -NCO content of the obtained mixed hydrophilic polyisocyanate curing agent was calculated to be 18.0%; its viscosity was measured to be 47.5 mPa·s; and its average particle size was measured to be 260.2 nm.

[0034] Infrared testing of the resulting mixed hydrophilic polyisocyanate curing agent, 2273cm -1 At -NCO, 1106cm -1 The ether bond absorption peak at , where -SO 3- The symmetric and asymmetric stretchi...

Embodiment 3

[0036]Add 70.0g of hexamethylene diisocyanate trimer to the three-necked flask, and pass through nitrogen; add 7.0g of polyethylene glycol monomethyl ether with a functionality of 0.998, and then raise the temperature to 75°C to allow the contents of the container to fully react for 5 hour; then lower the temperature to 20°C, then slowly add 0.7g of sodium ethylenediaminoethanesulfonate, and continue the reaction for 15 minutes; finally, after reaching room temperature, stop feeding nitrogen, take out to obtain a mixed hydrophilic polyisocyanate solidified agent.

[0037] The -NCO content of the obtained mixed hydrophilic polyisocyanate curing agent was calculated to be 17.3%; its viscosity was measured to be 51.3 mPa·s; and its average particle size was measured to be 248.3 nm.

[0038] Infrared testing of the resulting mixed hydrophilic polyisocyanate curing agent, 2273cm -1 At -NCO, 1106cm -1 The ether bond absorption peak at , where -SO 3 - The symmetric and asymmetric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com