PVC wiring channel

A technology of wiring troughs and wiring holes, which is applied in the field of PVC wiring troughs, can solve the problems of insufficient flexibility, insufficient flexibility, and high cost of wiring troughs, and achieve reduction of wiring trough breakage, simplified drilling steps, and toughness Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

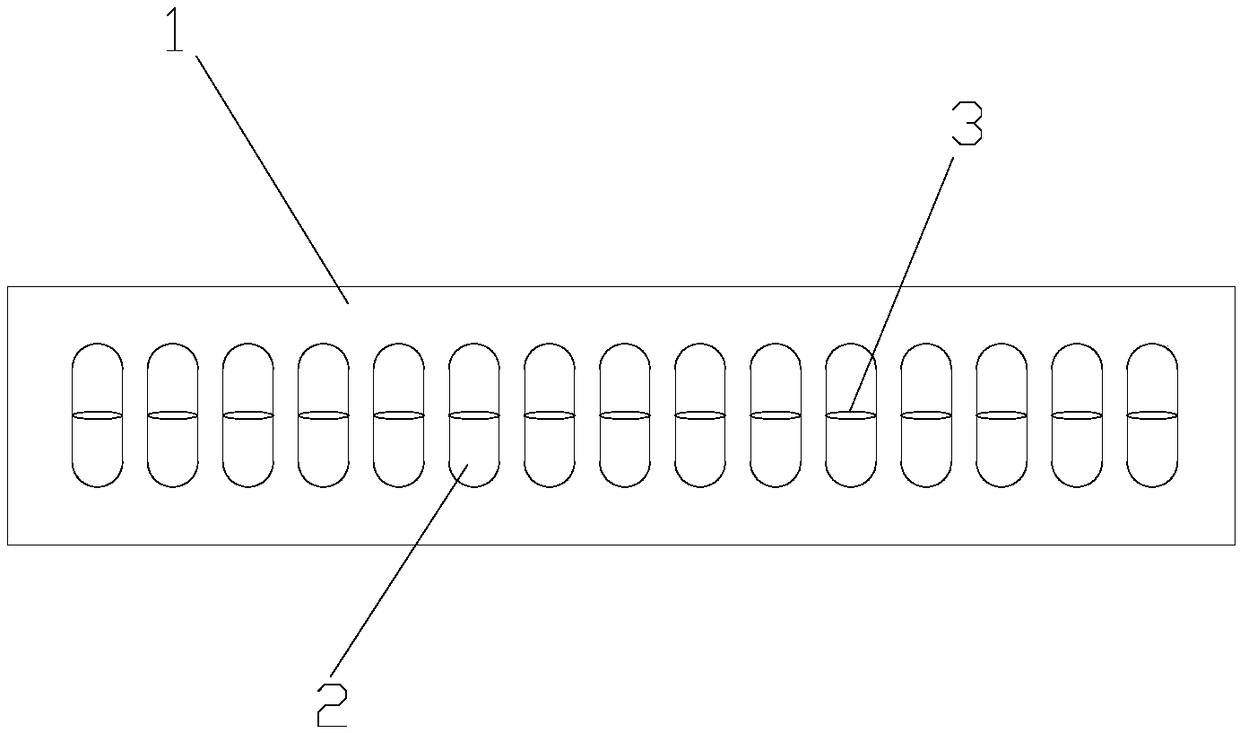

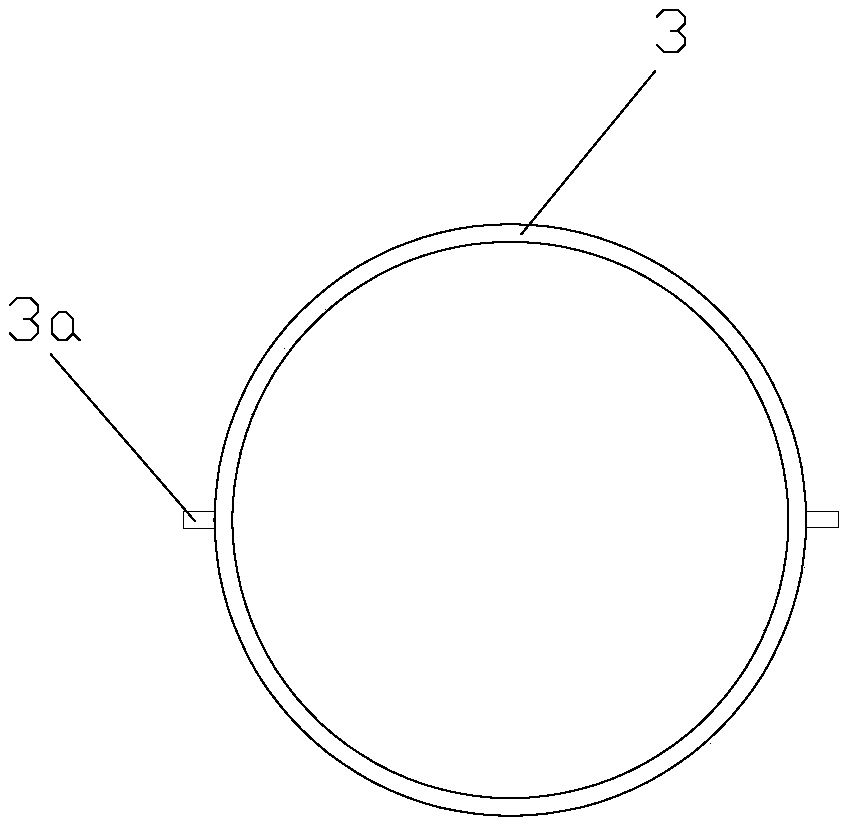

[0034] A PVC wiring trough provided in this embodiment has a structure such as Figure 1-2 As shown, the wiring board 1 is included, and the wiring board 1 is provided with a number of wiring holes 2 evenly distributed along its length direction. The wiring holes 2 are vertically arranged waist-shaped holes, and its height is greater than its width. It also includes a spacer 3 made of elastic material. The spacer 3 is detachably connected to the wiring hole 2. There is a left-right symmetrical connection hole in the middle of the inner edge of the wiring hole 2. The spacer 3 is provided with a matching connection hole. The connecting column 3a. Both sides of the spacer 3 can be rotatably connected to the wiring hole 2. When the spacer 3 is in a horizontal position, its plane is perpendicular to the plane of the wiring hole 2, and the wiring hole 2 is divided into two holes. .

[0035] The wiring board 1 raw material includes the following components in parts by weight: 95 pa...

Embodiment 2

[0050] The difference between the PVC wiring trough provided in this embodiment and Example 1 is that the raw material of the wiring board 1 includes the following components in parts by weight: 100 parts of polyvinyl chloride resin, 10 parts of nano-calcium carbonate composite particles 10 parts of chlorinated polyethylene, 7 parts of calcium zinc stabilizer, 4 parts of processing aid ACR.

[0051] Among them, the nano-calcium carbonate composite particles include the following components in parts by weight: 68 parts of nano-calcium carbonate filter cake, 2 parts of oxidized polyethylene wax, 2 parts of ammonium persulfate, 3 parts of butyl acrylate, methyl methacrylate 2 servings.

[0052] The preparation process of nano-calcium carbonate composite particles is as follows:

[0053] T1, the nano-calcium carbonate filter cake and water are mixed with 10% nano-calcium carbonate aqueous suspension:

[0054] T2. Add oxidized polyethylene wax, stir and disperse at 2900r / min high...

Embodiment 3

[0065] The difference between the PVC wiring trough provided in this embodiment and Example 1 is that the raw material of the wiring board 1 includes the following components in parts by weight: 105 parts of polyvinyl chloride resin, 12 parts of nano-calcium carbonate composite particles 12 parts, 12 parts of chlorinated polyethylene, 8 parts of calcium zinc stabilizer, 5 parts of processing aid ACR.

[0066] Wherein, the nano-calcium carbonate composite particles include the following components in parts by weight: 75 parts of nano-calcium carbonate filter cake, 2 parts of oxidized polyethylene wax, 3 parts of ammonium persulfate, 4 parts of butyl acrylate, methyl methacrylate 3 copies.

[0067] The preparation process of nano-calcium carbonate composite particles is as follows:

[0068] T1, the nano-calcium carbonate filter cake and water are mixed with 10% nano-calcium carbonate aqueous suspension:

[0069] T2. Add oxidized polyethylene wax, stir and disperse at 3000r / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com