Passive wireless thermal power plant wall temperature measurement system powered by temperature difference module

A passive wireless and measurement system technology, applied in the direction of measuring devices, measuring heat, signal transmission systems, etc., can solve the problems of wasting cables and occupying bridge space, etc., and achieve the effects of convenient installation, reduced maintenance costs, and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

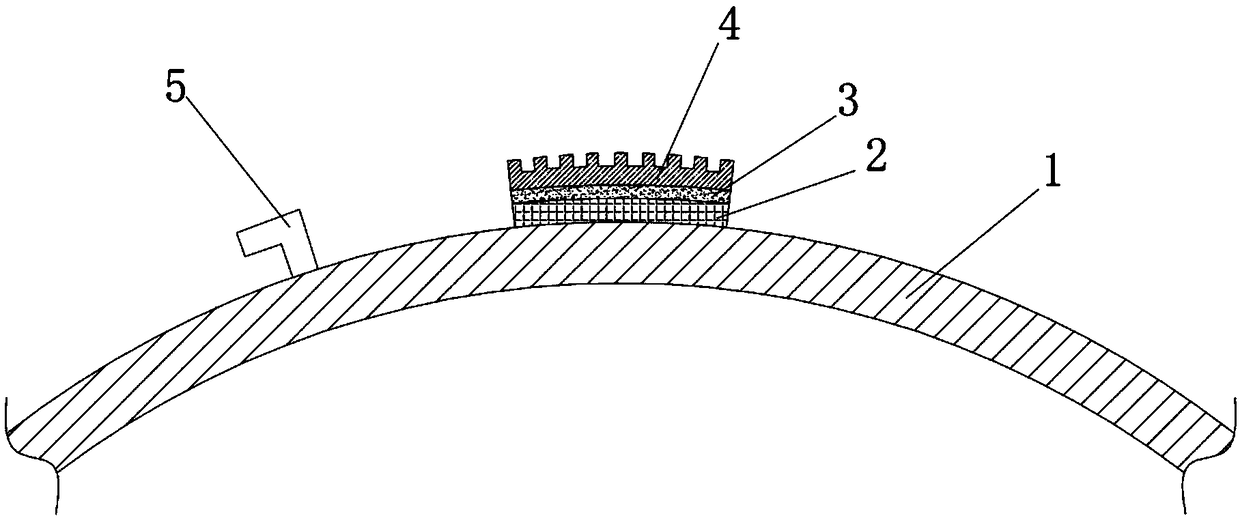

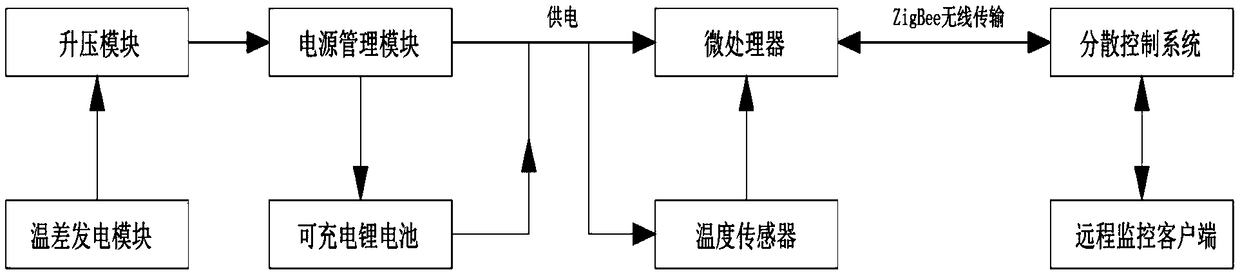

[0033] Depend on Figure 1-2 It is given that the present invention adopts a passive wireless thermal power plant wall temperature measurement system powered by a temperature difference module, including a thermoelectric power generation module 2, a microprocessor and a temperature sensor, and the thermoelectric power generation module 2 is closely attached to the outer surface of the wall 1 to be measured. The side of the thermoelectric power generation module that is close to the wall to be tested is used as the hot end, and the side away from the wall to be tested is used as the cold end. The surface of the cold end is coated with a thermally conductive silicone grease layer 3, and the outer surface of the thermally conductive silicone grease layer 3 is covered with a heat dissipation aluminum sheet 4 , constituting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com