Method for maintaining cigarette blending formulation

A technology of cigarette leaves and recipes, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of long-term maintenance and design methods, long processes, complicated steps, etc., and achieve comprehensive and important quality information of tobacco leaves. Good performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described in detail below in conjunction with the examples.

[0055] Those skilled in the art will understand that the following examples are only for illustrating the present invention and should not be considered as limiting the scope of the present invention. If no specific technique or condition is indicated in the examples, it shall be carried out according to the technique or condition described in the literature in this field or according to the product specification. The reagents or instruments used were not indicated by the manufacturer, and they were all conventional products that could be purchased.

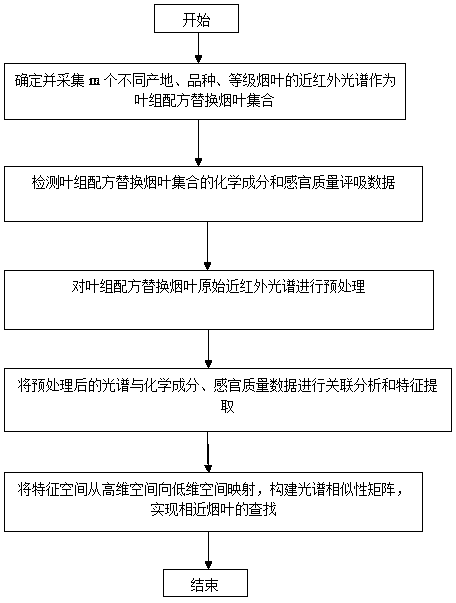

[0056] The cigarette leaf group formula maintenance method of the present embodiment comprises the following steps:

[0057] Step (1), sample collection: collect m stock tobacco leaf samples from 2015 to 2018, here select 360 tobacco leaf samples, ie m=360.

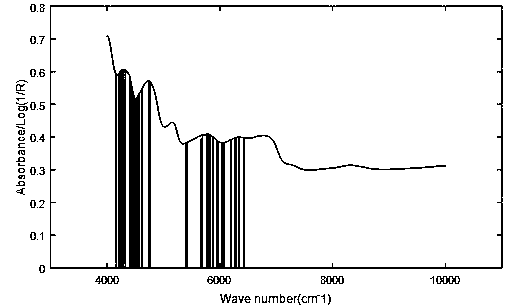

[0058] The near-infrared spectral data of tobacco leaf samples w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com