Modular underwater pressure-resistant sound insulation baffle

A modular, sound insulation barrier technology, applied in the direction of sounding equipment, instruments, etc., can solve the problems of difficult adaptation to the use environment, unsuitable for pressure environments, etc., and achieves easy batch processing, easy modular tailoring, good medium and low frequency isolation. sound effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below.

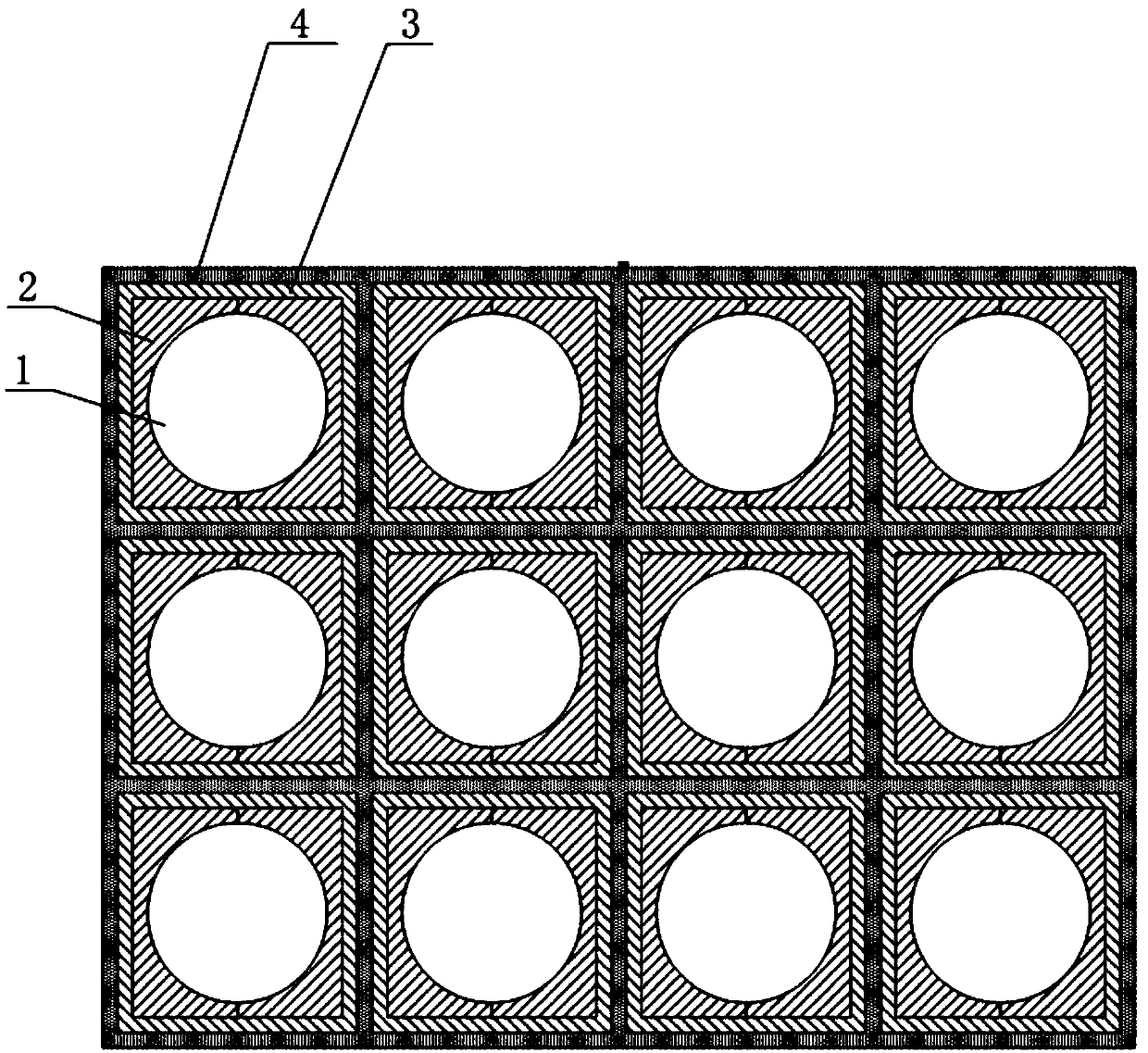

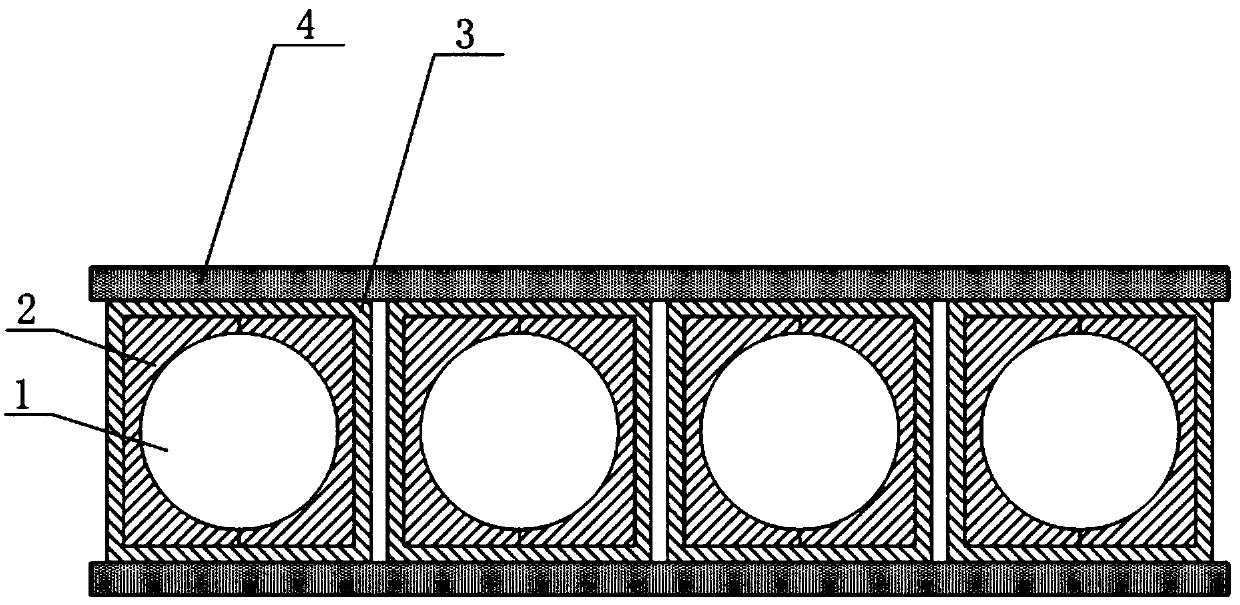

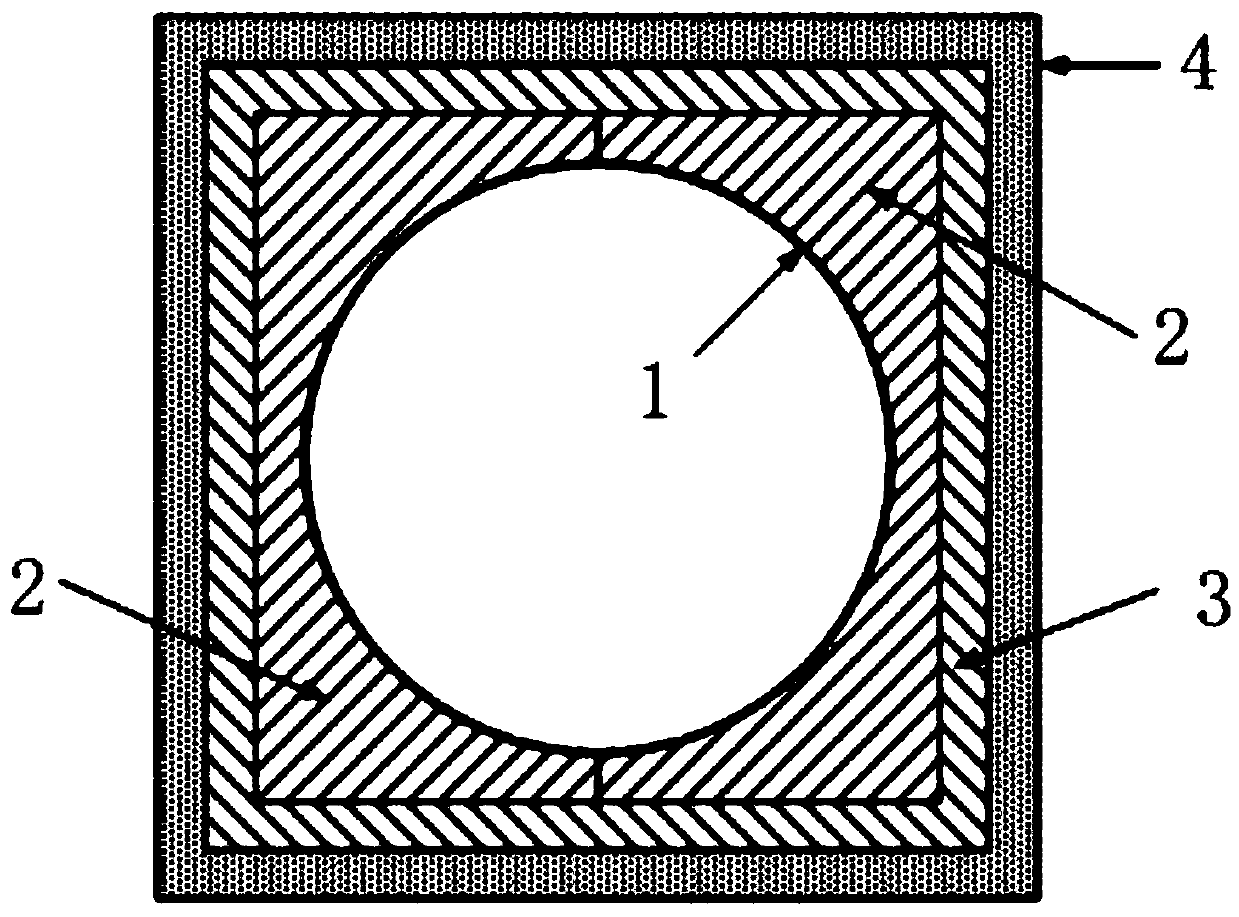

[0023] Such as Figure 1 to Figure 4 As shown, a modular underwater pressure-resistant sound insulation baffle is formed by pasting several modules to form a baffle structure. The module includes a hollow and sealed spherical shell 1, which is a stainless steel shell. The stainless steel shell is to ensure the pressure resistance of the air ball cavity. The hollow interior of the spherical shell 1 is an air balloon cavity, and the acoustic impedance of the air balloon cavity is smaller than that of water. The outer periphery of the spherical shell 1 is covered with silicon rubber 2, and the outer periphery of the silicon rubber 2 is covered with a shell 3. The shell 3 is a rubber cube shell, and the rubber cube shell is rectangular. A vulcanized rubber plate 4 is bonded to the outer periphery of the casing 3 . Such as figure 1 As shown, the above-mentioned silicone rubber 2 is composed of two c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com