Novel straw recovery device

A technology for recycling device and straw, which is applied to mixers with rotary stirring devices, transportation and packaging, mixers, etc., can solve the problems of cumbersome operation process and easy to fall apart, and achieves avoiding scattered lumps, improving efficiency and improving intelligence. effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

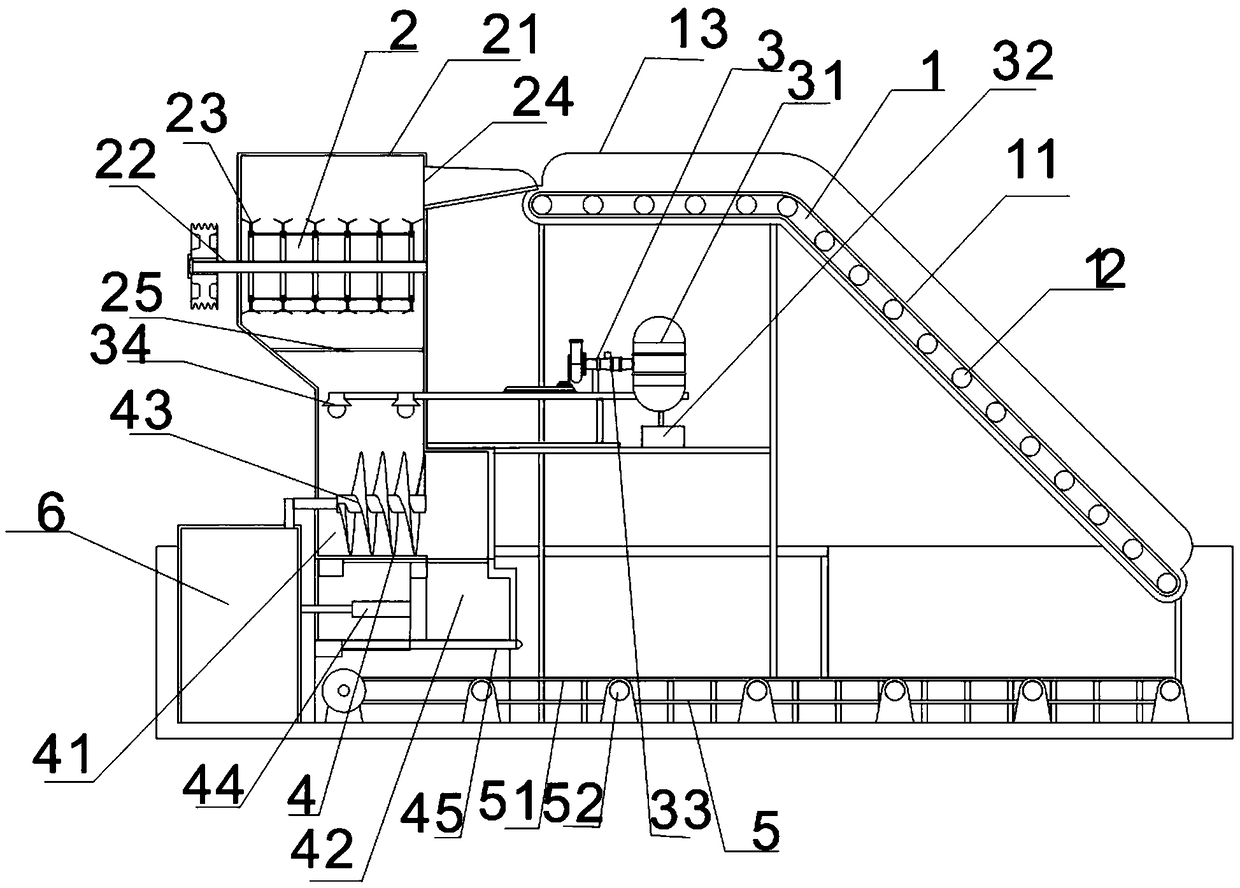

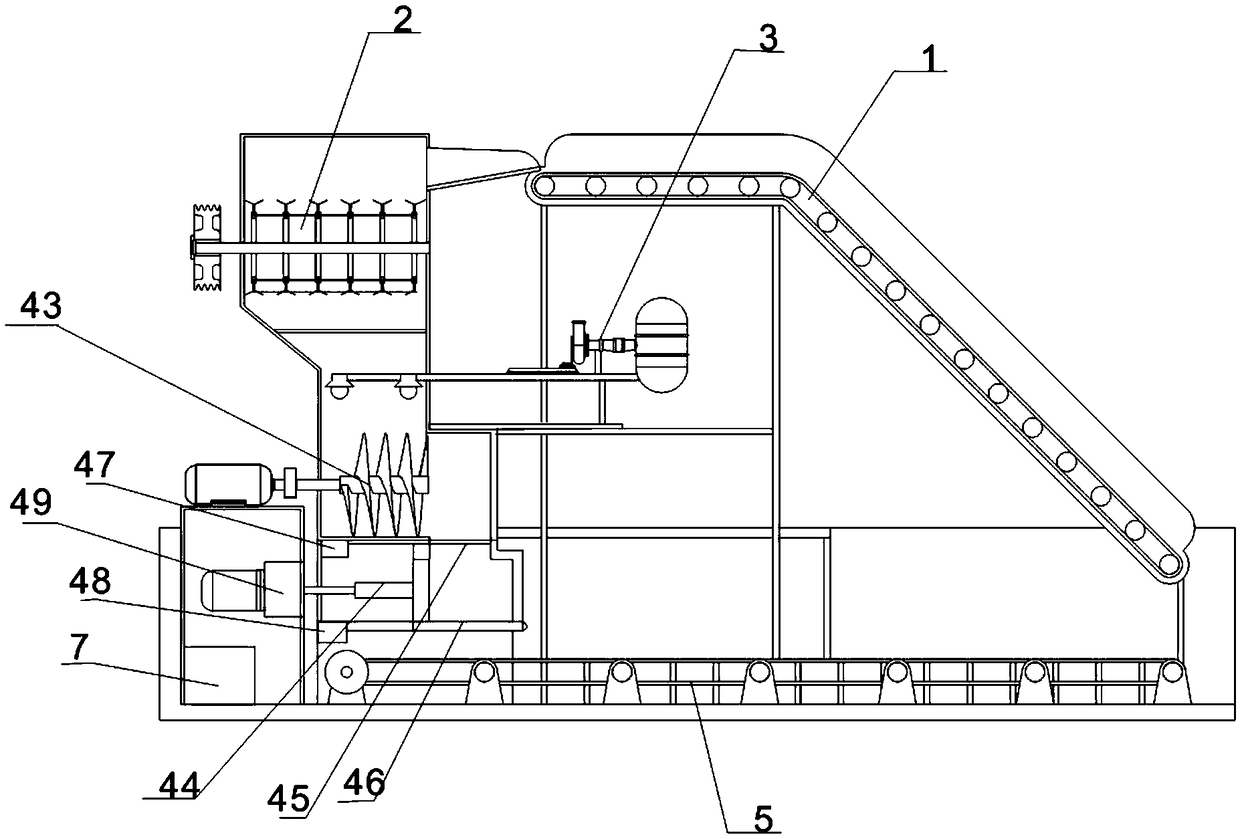

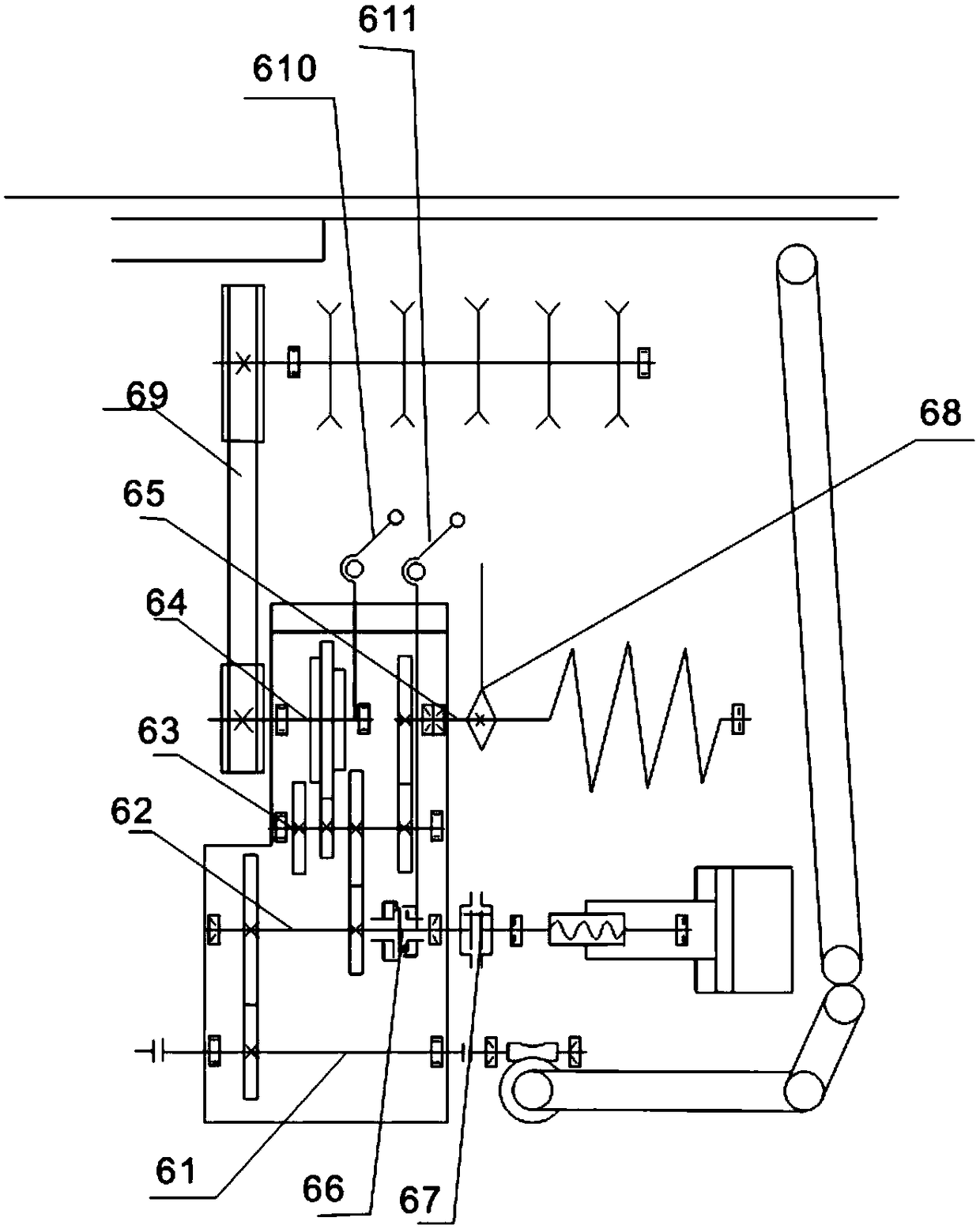

[0025] In one embodiment of the present invention, as Figure 1-4 As shown, a new type of straw recovery device is provided, including a feeding device 1, a crushing device 2, a spraying device 3, a stirring and compressing device 4, a transmission device 5 and a transmission speed regulating distribution device 6, and the crushing device 2 is arranged on the feeding device On one side of the device 1, the stirring and compressing device 4 is arranged at the lower part of the crushing device 2, the spray device 3 is arranged at the side of the crushing device 2, and is arranged at the lower part of the feeding device 1, and the conveying device 5 is arranged at the crushing device 2 and the spray device 3 In the lower part, the transmission speed regulating distribution device 6 is arranged on the other side of the crushing device 2, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com