Tobacco fragrance enhancer containing vetiver essential oil

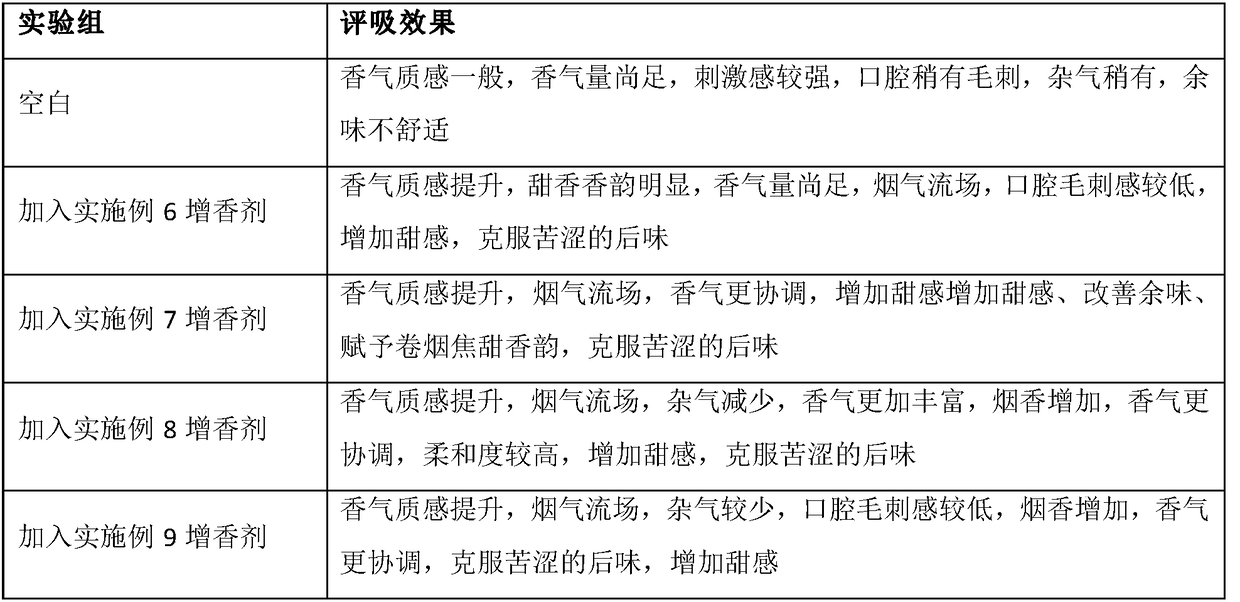

A technology of vetiver essential oil and flavor enhancer, applied in the field of tobacco, can solve the problems of less pure tobacco aroma, unpleasant residual taste, insufficient alcohol and the like, and achieve the effects of enhancing tobacco taste, rich aroma and improving aftertaste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Preparation of Vetiver Essential Oil Serum

[0037] The vetiver essential oil in this example is extracted from the root of the bluestem plant vetiver Andropogon muricatus, and the product is directly purchased from the market.

[0038] Add 20 times the weight of 60% ethanol aqueous solution to the vetiver essential oil, stir evenly and let stand at room temperature for 12 hours, filter the filtrate with an 80-mesh filter, and put the filtrate at a temperature of 50°C to 60°C, Under the condition of -0.1MPa, carry out vacuum concentration, so that the density of the concentrated slurry reaches 0.936±0.005g / cm 3 , to obtain vetiver essential oil slurry.

Embodiment 2

[0039] Embodiment 2: honey slurry deployment

[0040] The honey in the present embodiment selects commercially available milk vetch honey.

[0041] (a) add the pure water of its weight 10 times amount in honey, standby after dissolving;

[0042] (b) In the aqueous solution of honey after dissolving in step (a), add its equal weight, the mass fraction is 75% ethanol aqueous solution, after stirring evenly, stand at 0 ℃~5 ℃ for 18 hours~24 hours, use 100 The filtrate is obtained by filtering through a mesh filter, and the filtrate is concentrated under reduced pressure at a temperature of 50°C to 60°C and a pressure of -0.08MPa to 0.1MPa, so that the density of the concentrated slurry reaches 1.24±0.008g / cm 3 .

Embodiment 3

[0043] Embodiment 3: preparation of tobacco extract

[0044] Step (1): The raw material for extraction is selected from tobacco scraps or tobacco stems of Burley tobacco or oriental tobacco, adding 25% saturated aqueous solution of L-lysine in an amount of 10% of the tobacco mass to the tobacco raw material, and placing it in a closed environment 12 hours, and then baked at 70°C for 4 hours.

[0045] Step (2): The cured tobacco raw material is pulverized to 40 meshes with a HT400 pulverizer.

[0046] Step (3): Add butane to the tobacco powder, the amount of butane is 10 times the mass of the tobacco raw material, extract at 30° C. for 2 hours, and concentrate the extraction solvent to obtain a concentrate.

[0047] Step (4): Add 95% ethanol to the concentrate, the amount of ethanol is 5 times the mass of the concentrate, raise the temperature to 40°C, keep it for 1.0 hour, so that the extract is completely dissolved in the alcohol, after cooling, cool down to -10 ℃~5℃, maint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com