Insulating supporting strip automatic feeding device for insulating part assembling machining

A technology of insulating stays and automatic feeding, which is applied to conveyor objects, transportation and packaging, conveyors, etc., can solve problems such as difficulty in controlling the spacing of insulating stays, equipment cost, and large occupation of production workshops, restricting the production of insulating parts, etc. , to ensure the accuracy of the assembly, improve production efficiency, and reduce equipment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

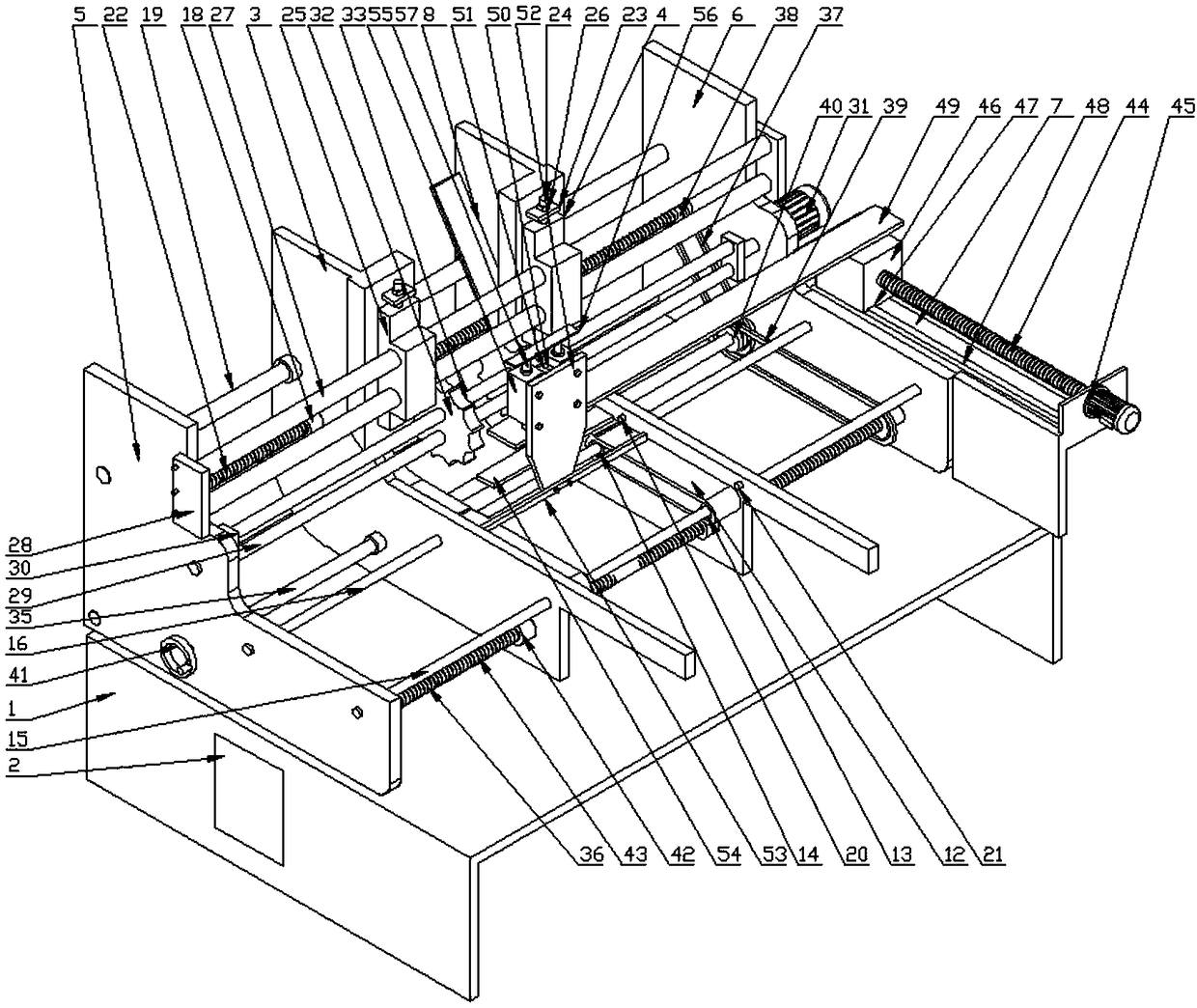

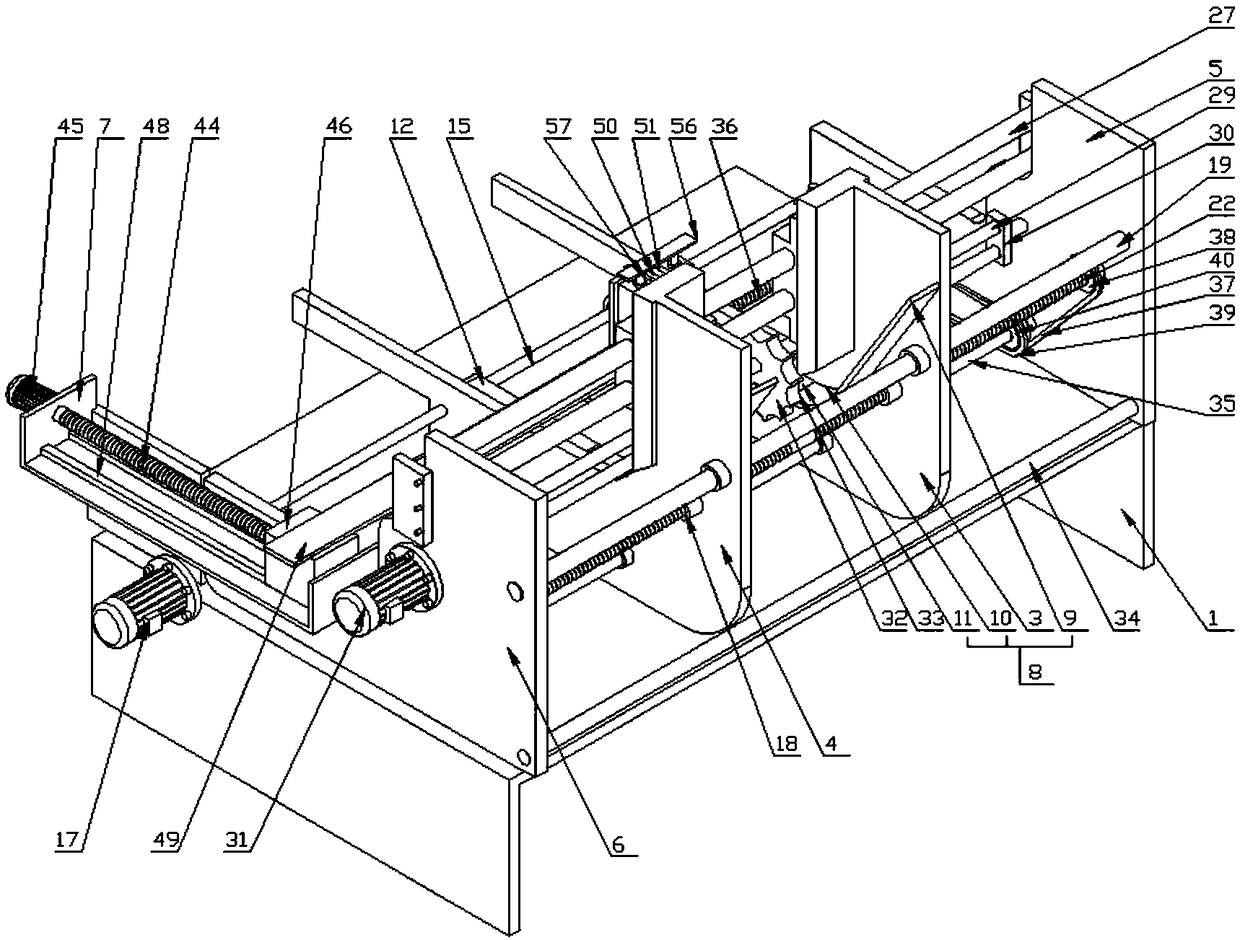

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] An automatic insulating brace feeding device for insulating assembly blank processing, comprising a machine tool 1, on which a PLC controller 2, a first supporting plate 3, a second supporting plate 4, and a first side guard plate 5 are provided , The second side guard 6 and the side frame 7, the first support board 3 and the second support board 4 have the same structure, and are symmetrically arranged between the first side guard 5 and the second side guard 6, the The first support plate 3 has an L-shaped structure, and an upper plate 8 is provided on the inner wall. The upper plate 8 includes an inclined plate 9, an arc plate 10, and a horizontal plate 11 connected in sequence. A conveyor belt 12 is provided. The inner wall of the conveyor belt 12 is provided with a driving wheel 13 and a driven wheel 14. The driving wheel 13 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com