Lifting type self-controlled aeration system with multiple groups of rails

An aeration system and lifting technology, which is applied in the field of multi-group track lifting self-controlled aeration system, can solve problems such as broken aeration hoses and impracticality, and achieve saving of operation and maintenance costs, reduction of lifting resistance, and distribution of aeration uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

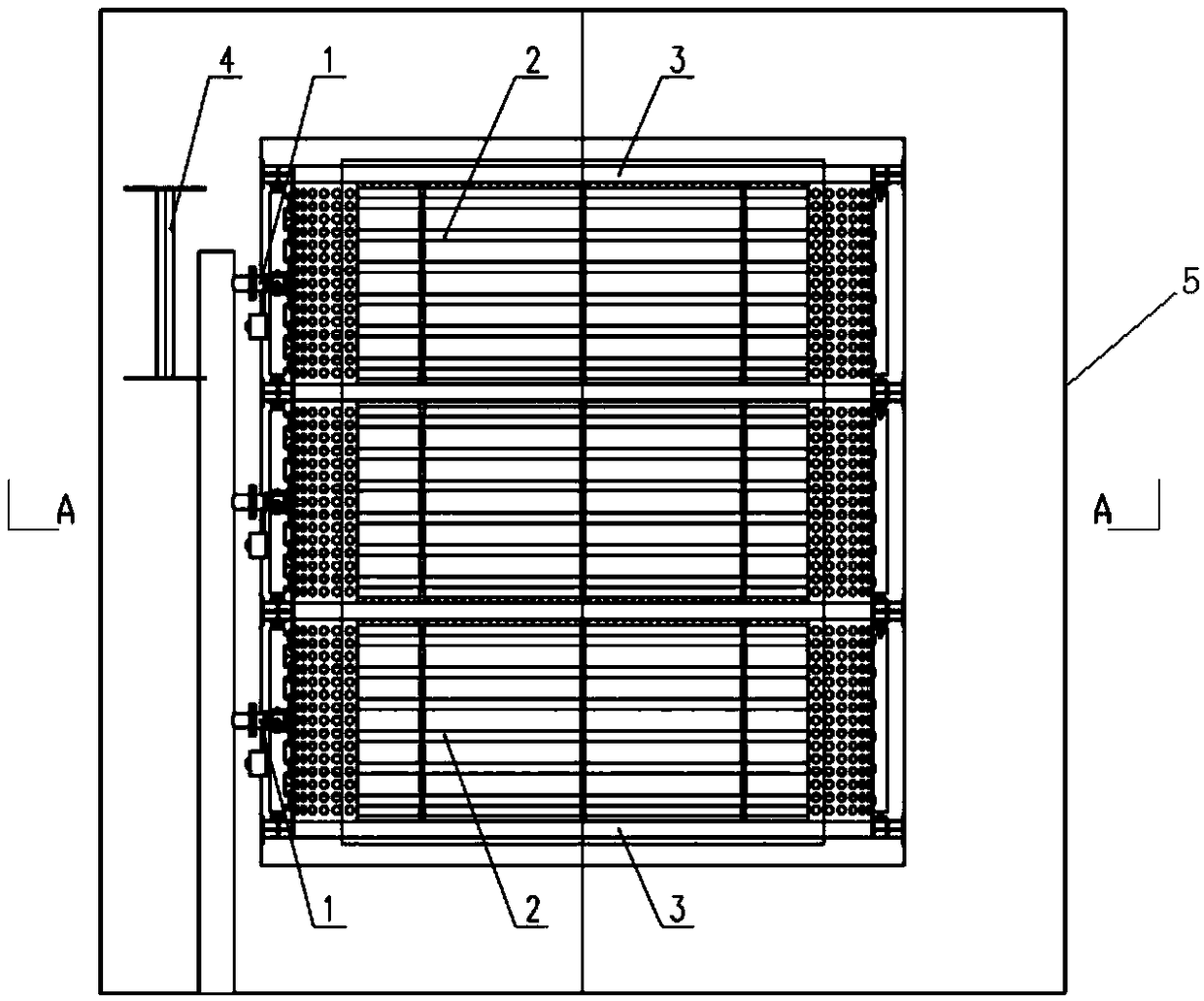

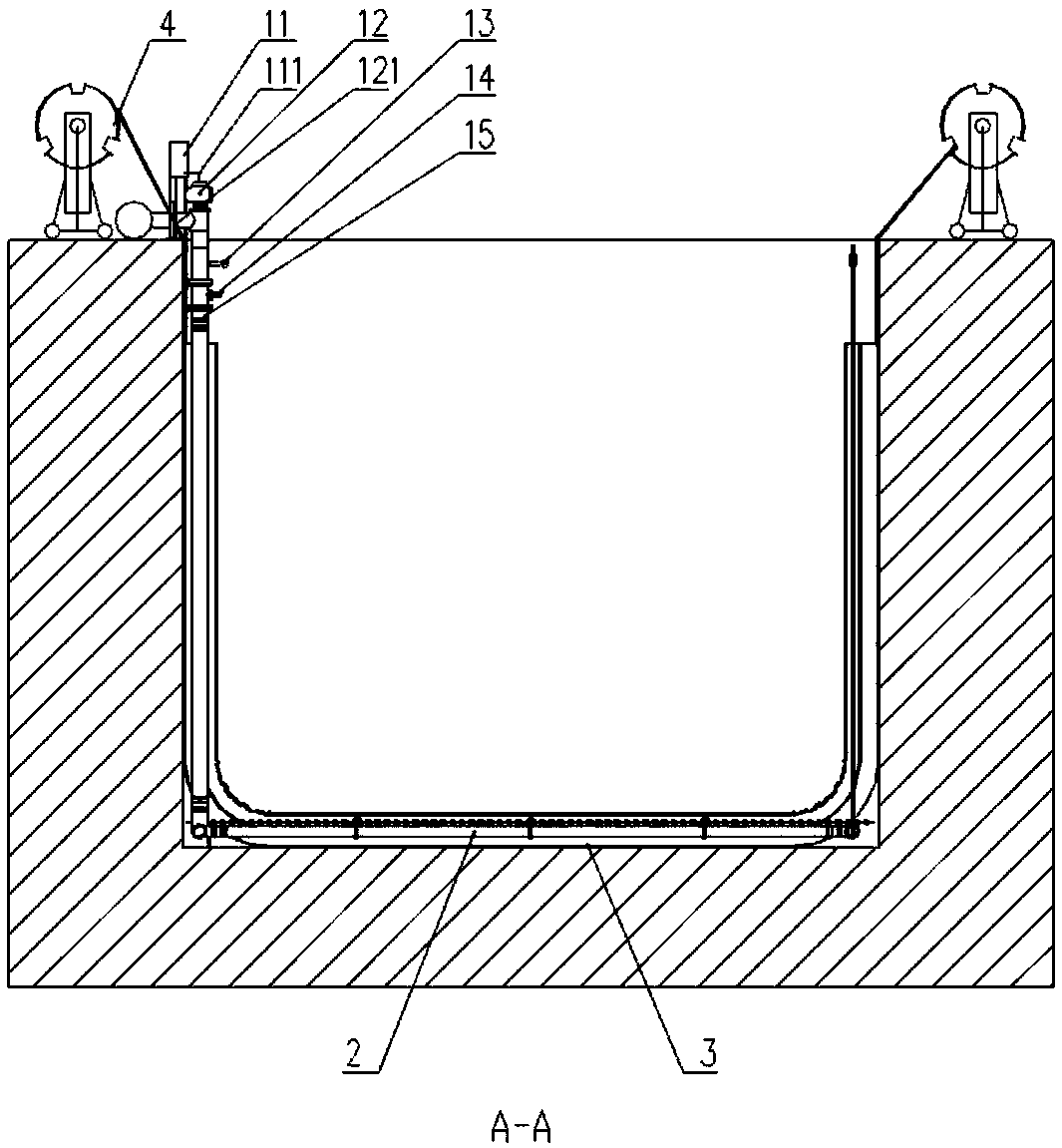

[0045] Multiple sets of track lifting self-control aeration system, including measurement and control component 1, aeration component 2, track component 3, lifting tool cart 4.

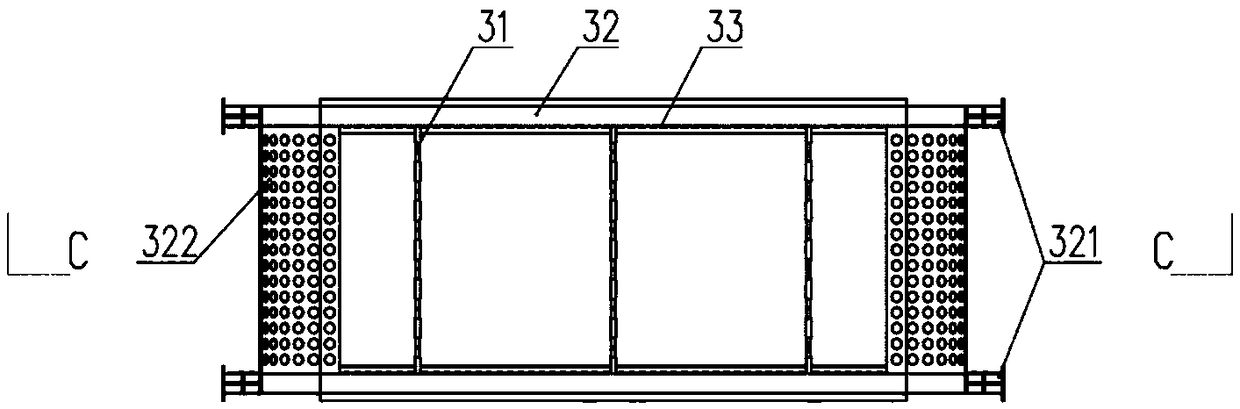

[0046] The aeration assembly includes an intake hose 21, a distribution pipe 22, an aeration flexible hose 23, a communication pipe 24, an exhaust hose 25, and a drain valve 26. The air inlet of the air intake hose is flexibly connected to the measurement and control component, and its air outlet is flexibly connected to the main pipe of the distribution pipe. The distribution pipes are multi-way hard pipes with different diameters (steel pipes or hard plastic pipes), and N of them are distributed according to professional requirements. The air outlet with different diameters is flexibly connected with the aeration flexible hose, and the aeration flexible hose is evenly opened with a certain number and shape (one-shaped or cross or triangular) micro The end of the hole is flexibly connected with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com