Garbage hydrolysis formula

A formula, waste technology, applied in the direction of organic fertilizer, climate change adaptation, etc., can solve the problems of slow heat dissipation, affecting production progress, unable to achieve hydrolysis effect, etc., to achieve the effect of short fermentation time and complete hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

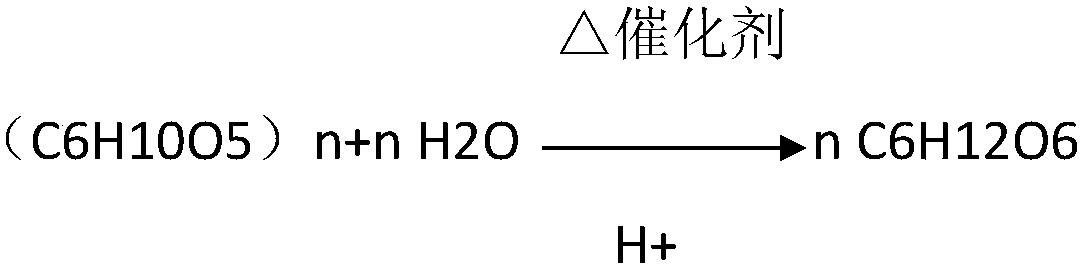

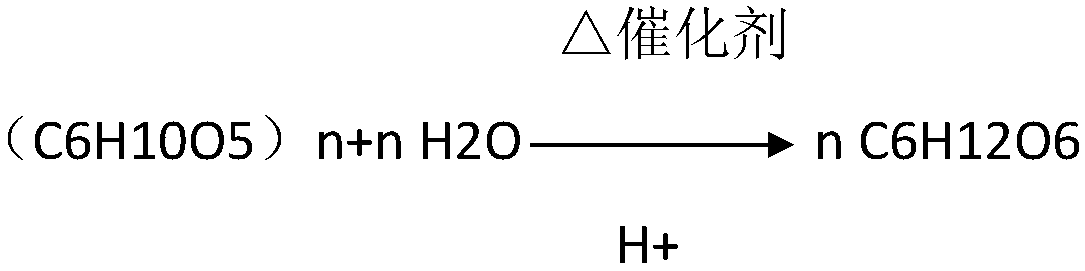

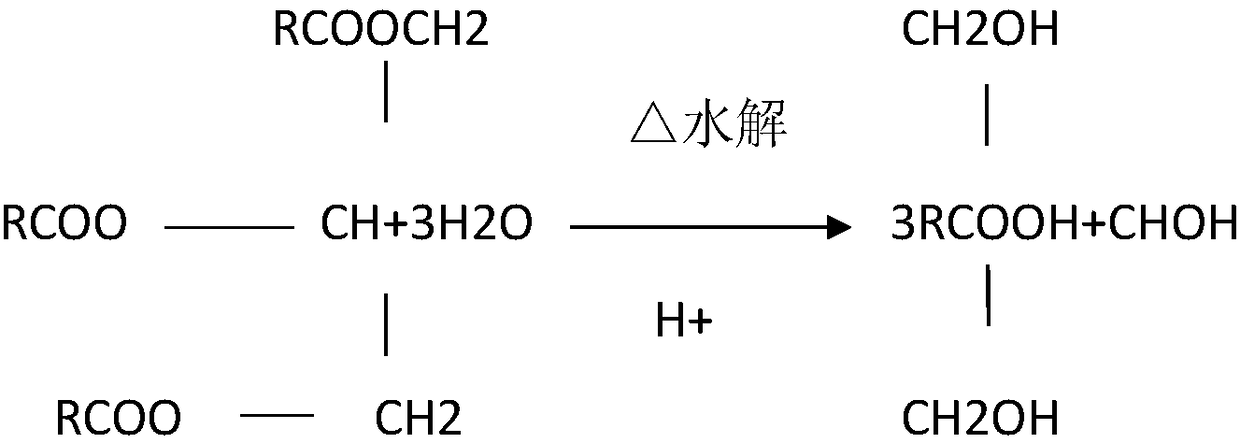

Method used

Image

Examples

Embodiment 1

[0021] A garbage hydrolysis formula, comprising the following steps:

[0022] Step 1: sending the sorted organic matter into a horizontal hydrolysis tank;

[0023] Step 2: Spray the dilute sulfuric acid solution on the sorted organic matter, heat the horizontal hydrolysis tank to a high temperature of 180°C and simultaneously apply a high pressure of 1.0Mpa to carry out the hydrolysis reaction;

[0024] Step 3: high temperature and high pressure hydrolysis reaction for 2 hours;

[0025] Step 4: Lower the temperature in the horizontal hydrolysis tank to 40°C and normal pressure (0-0.1Mpa is normal pressure);

[0026] Step 5: Then spray into the bio-enzyme catalyst to completely hydrolyze the sorted organic matter and play a role in fixing ammonia.

[0027] Further, the concentration of the dilute sulfuric acid solution described in step 2 is 25%-35%.

[0028] Further, the spraying amount of the dilute sulfuric acid solution and the sorted organic matter described in step 2 i...

Embodiment 2

[0032] Embodiment 1 Further, the concentration of the dilute sulfuric acid solution described in step 2 is 25%.

[0033] Further, the spraying amount of the dilute sulfuric acid solution described in step 2 and the sorted organic matter is 0.12L / m 3

[0034] Further, the biological enzyme catalyst described in step 5 includes 30 parts of peptidase, 10 parts of lipase, 18 parts of cellulase, 6 parts of ribozyme and 936 parts of water, and the resulting solution is fully mixed.

[0035] Further, the spraying amount of the biological enzyme catalyst described in step 5 and the sorted organic matter is 5L / m 3 .

Embodiment 3

[0037] Embodiment 1 Further, the concentration of the dilute sulfuric acid solution described in step 2 is 35%.

[0038] Further, the spraying amount of the dilute sulfuric acid solution described in step 2 and the selected organic matter is 0.08L / m 3 .

[0039] Further, the biological enzyme catalyst described in step 5 includes 40 parts of peptidase, 16 parts of lipase, 22 parts of cellulase, 9 parts of ribozyme and 913 parts of water, and the resulting solution is fully mixed.

[0040] Further, the spraying amount of the biological enzyme catalyst described in step 5 and the sorted organic matter is 3L / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com