Self-resetting concrete-filled circular steel tube frame beam-column joint with energy dissipation parts on webs

A technology of beam-column joints and concrete columns, which is applied in the direction of building components, earthquake resistance, building types, etc., can solve the problems of inner partitions, difficult replacement of energy-consuming parts, and damage to floors, etc., to achieve uniform force distribution and reduce labor costs , to achieve the effect of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific examples, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the protection scope of the present invention.

[0034] In the present invention, unless stated to the contrary, the used orientation words such as "upper and lower" generally refer to definitions based on the drawings of the corresponding drawings.

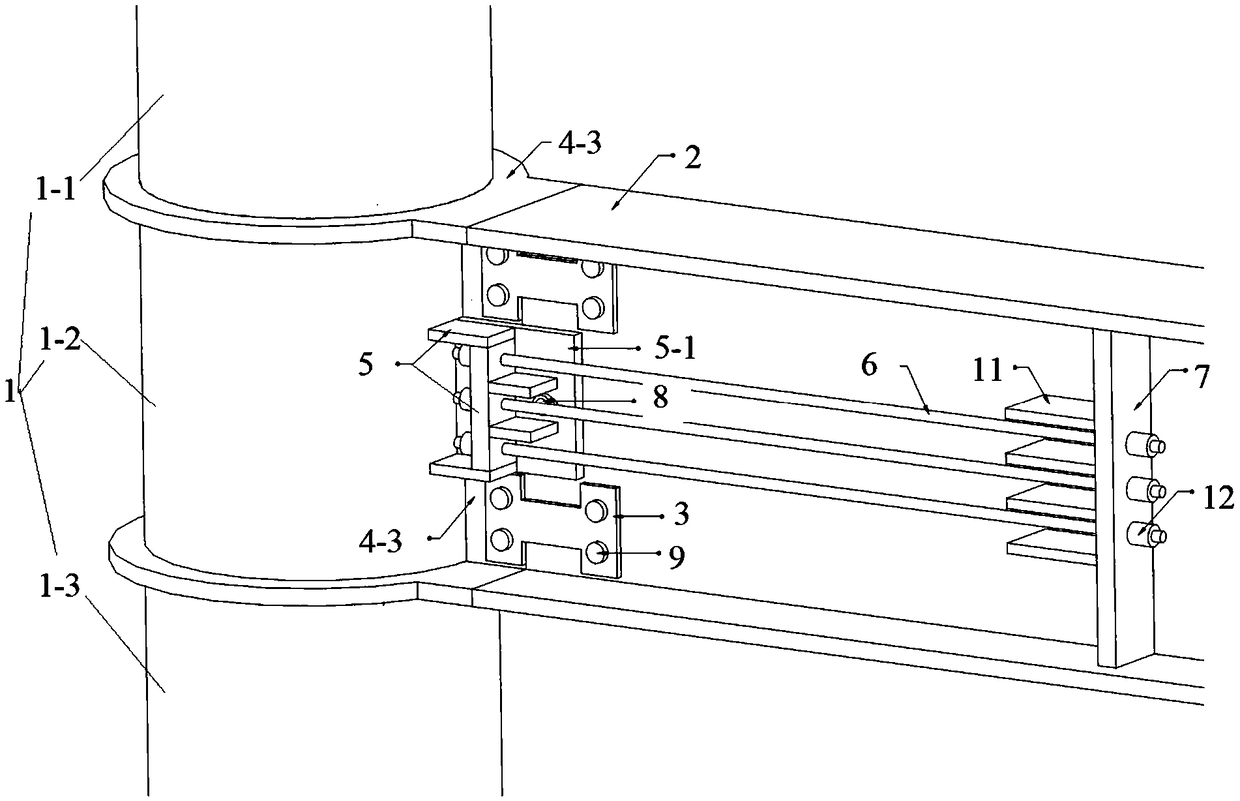

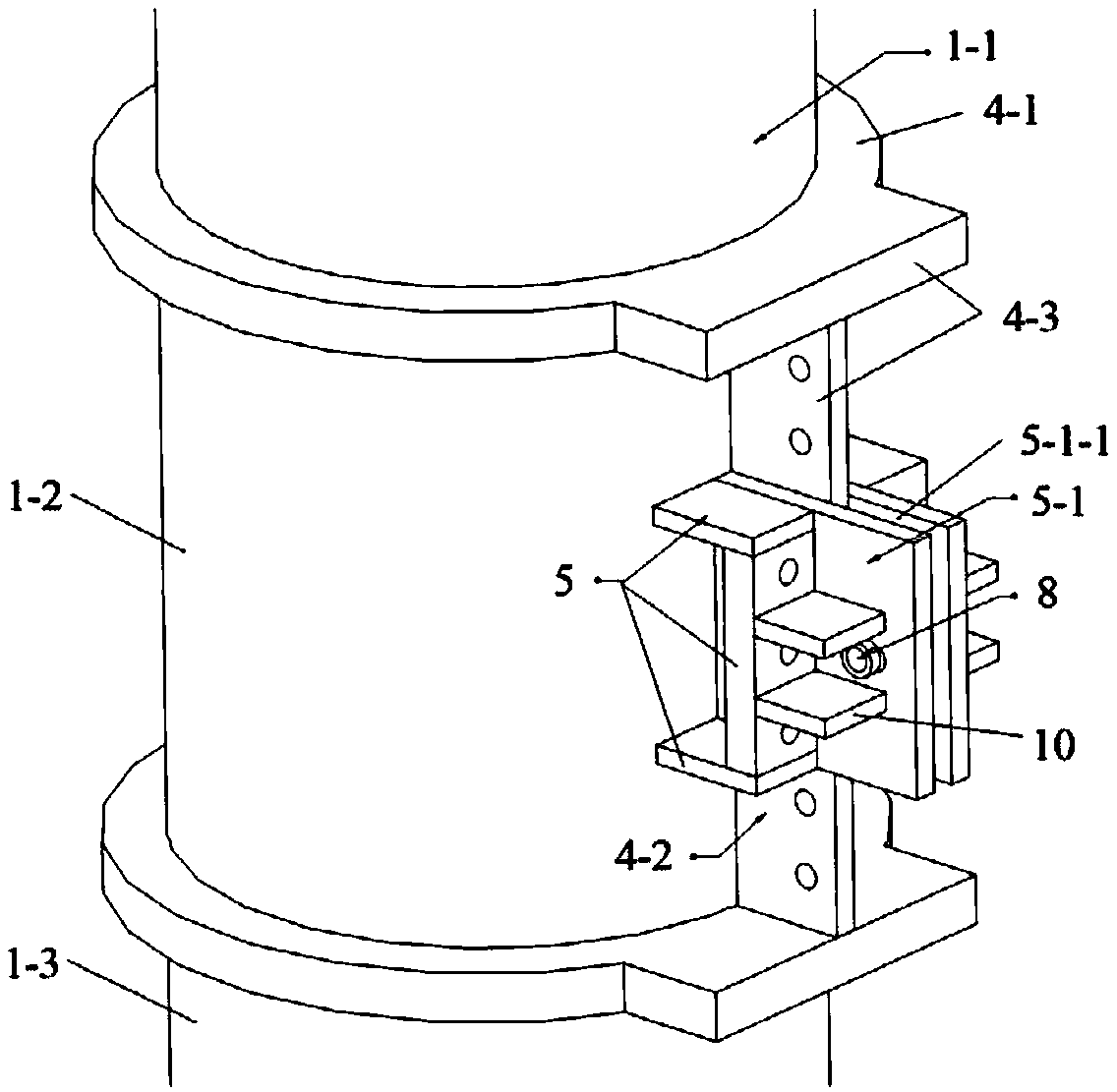

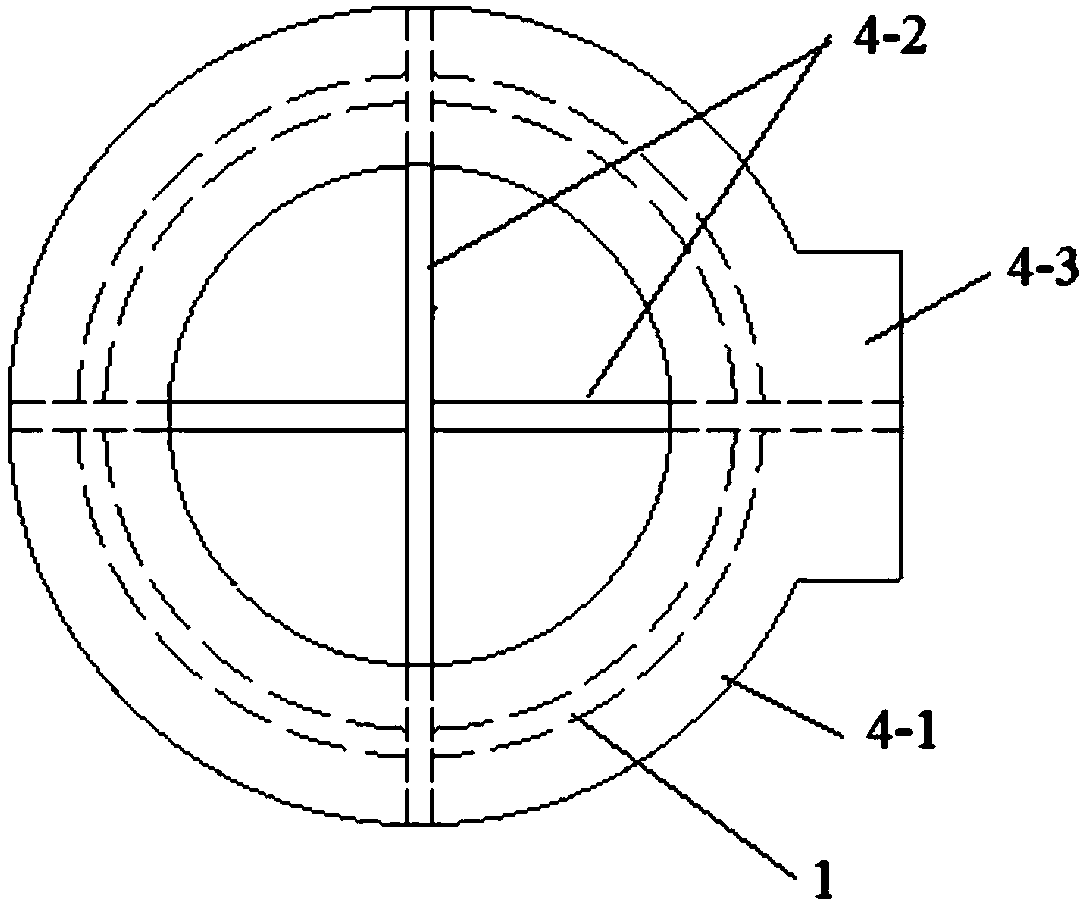

[0035] Such as figure 1 As shown, the present invention discloses a self-resetting circular steel pipe concrete frame beam-column node with energy-dissipating parts on the web, including a circular steel pipe concrete column 1, an H-shaped steel beam 2, an energy-dissipating part 3, a column connector 4, Groove connector 5, prestressed steel strand 6 and anchor plate 7; column connector 4 includes annular plate 4-1 and column through plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com