A multi-platform self-waterproof foundation pit enclosure structure without internal support and its construction method

A technology for waterproofing foundation pits and enclosure structures, which is applied in the direction of foundation structure engineering, excavation, construction, etc., and can solve problems such as poor sealing effect of enclosure structures, unsuitability for foundation pit support, and the impact of surrounding environments, so as to speed up the overall Construction speed, ease of implementation, and high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

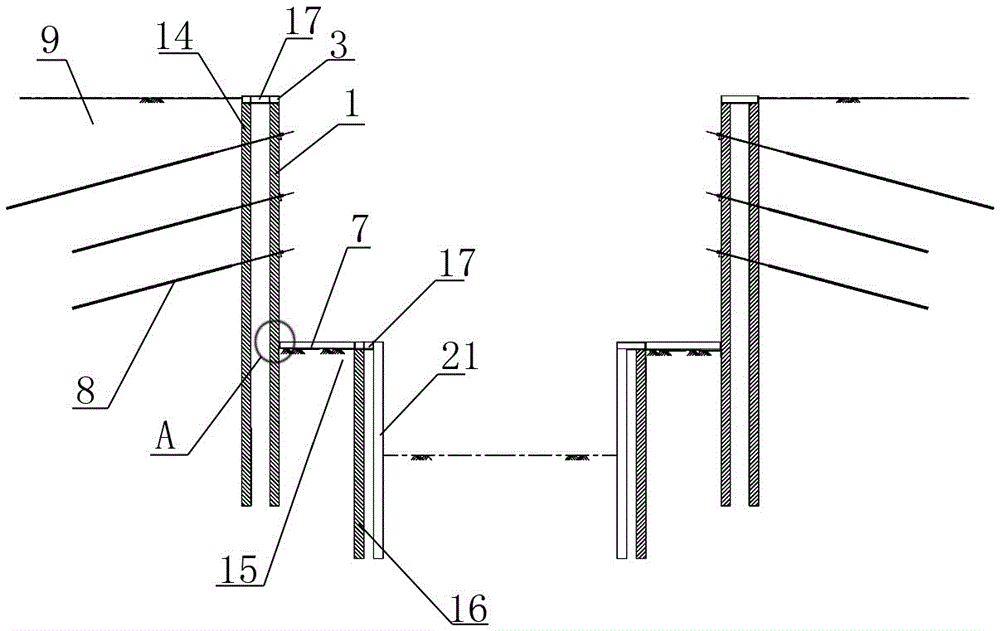

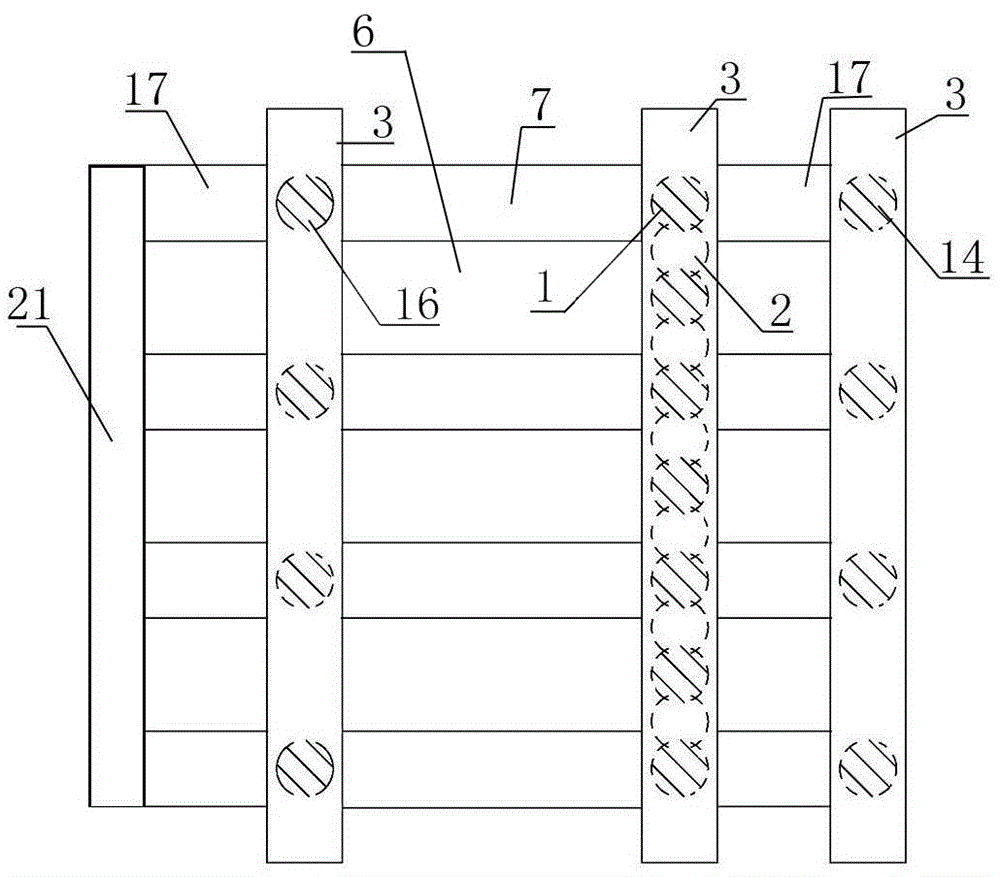

[0045] Embodiment one sees figure 1 and figure 2 as well as Figure 5 to Figure 8 As shown, a multi-platform non-inner support self-waterproof foundation pit enclosure structure is enclosed in the soil 9 around the foundation pit, including an outer enclosure, at least one inner enclosure, and a pulley between the two A knot device, wherein the inner enclosure is low and located at the inner ring of the foundation pit, and the outer enclosure is high and located at the outer ring of the foundation pit, forming a stepped shape with an outer high and an inner low;

[0046] The outer enclosure device includes continuous high enclosure components arranged in the front row, intermittent anti-side elevation piles 14 arranged in the rear row and connecting beams 17 arranged between the tops of the two, and the high enclosure components The cap beam 3 perpendicular to the connecting beam 17 is arranged on the top of the anti-side high pile 14;

[0047] The inner enclosure device a...

Embodiment 2

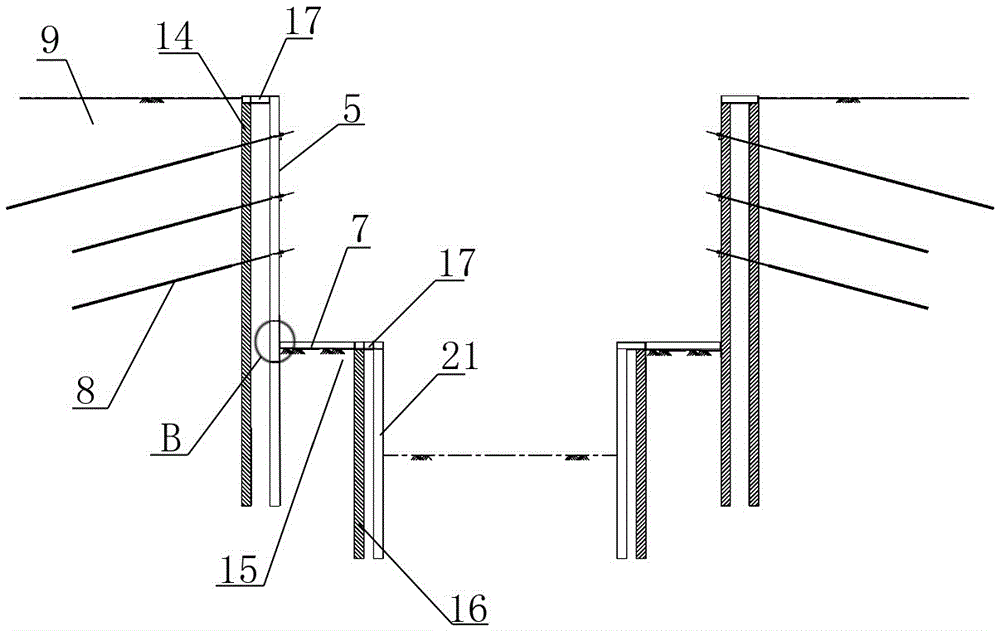

[0057] Embodiment two, see image 3 and Figure 4 as well as Figure 9 to Figure 12 , different from Embodiment 1, the short enclosure component is the low wall 21 of the underground diaphragm wall, the high enclosure component is the high wall 5 of the underground diaphragm wall, the high wall 5 of the underground diaphragm wall and the tie beam 7 The rigid connections are L-shaped stretched steel bars 10, L-shaped bent steel bars 18, planted bars 12 or groove-shaped bent steel bars 20, and the groove-shaped bent steel bars 20 are connected with the main bars of tie beams 7 through welds 19. The L-shaped bent steel bar 18 is connected to the main bar of the tie beam 7 through the casing 11 . An anchor rod A8 that is obliquely arranged from the outer enclosure to the soil 9 around the foundation pit.

[0058] The construction method of the above-mentioned multi-platform non-inner support self-waterproof foundation pit enclosure structure is characterized in that the steps a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com