Construction technique for hoisting steel made coal hopper on-site

A construction process and technology for steel coal hoppers, which are applied to lifting devices, hoisting devices, construction materials processing and other directions, can solve the problems of high cost, long construction period, delay in civil construction period, etc., and achieve low cost and short installation and construction period. , The effect of simple and easy construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

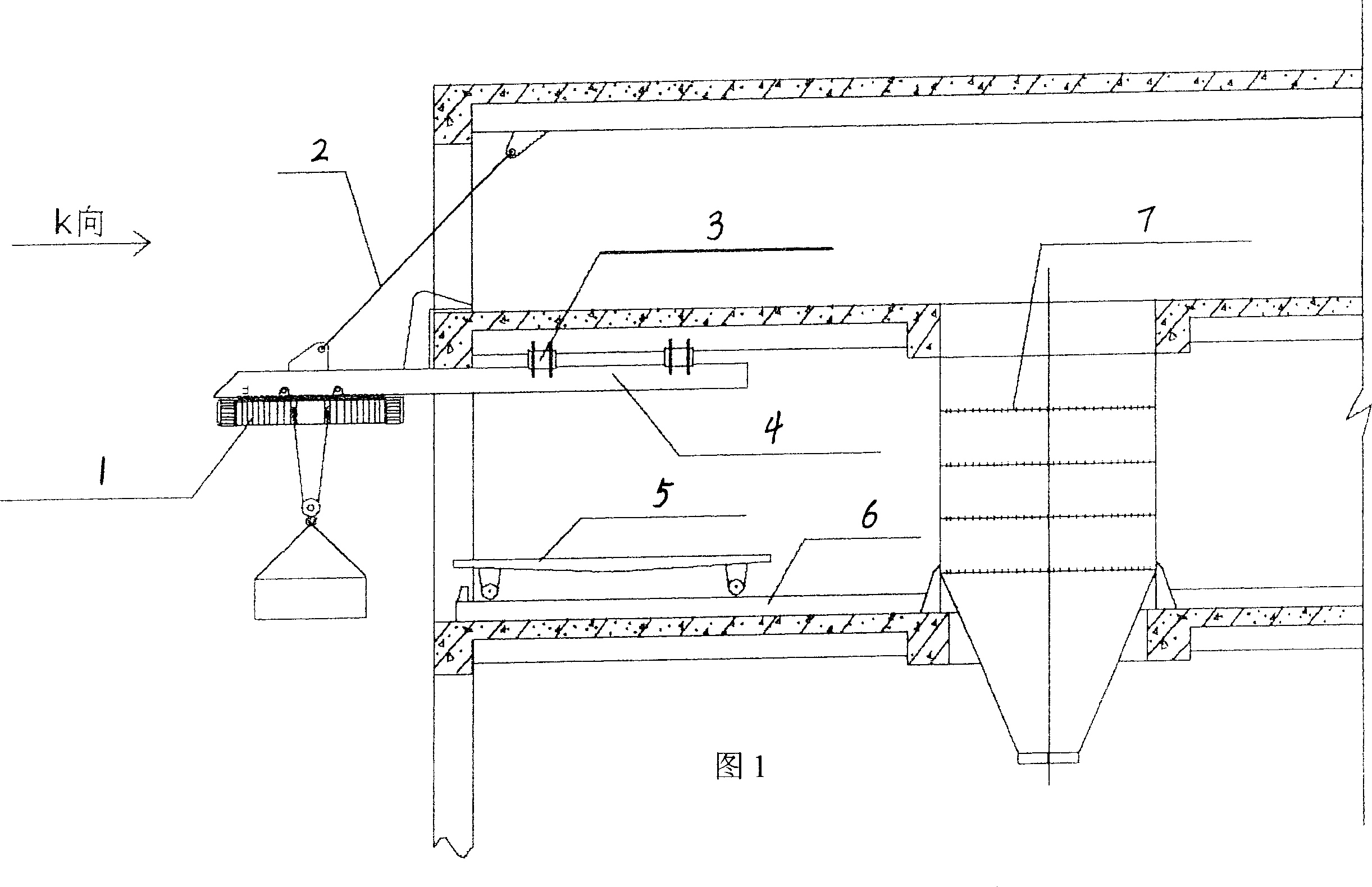

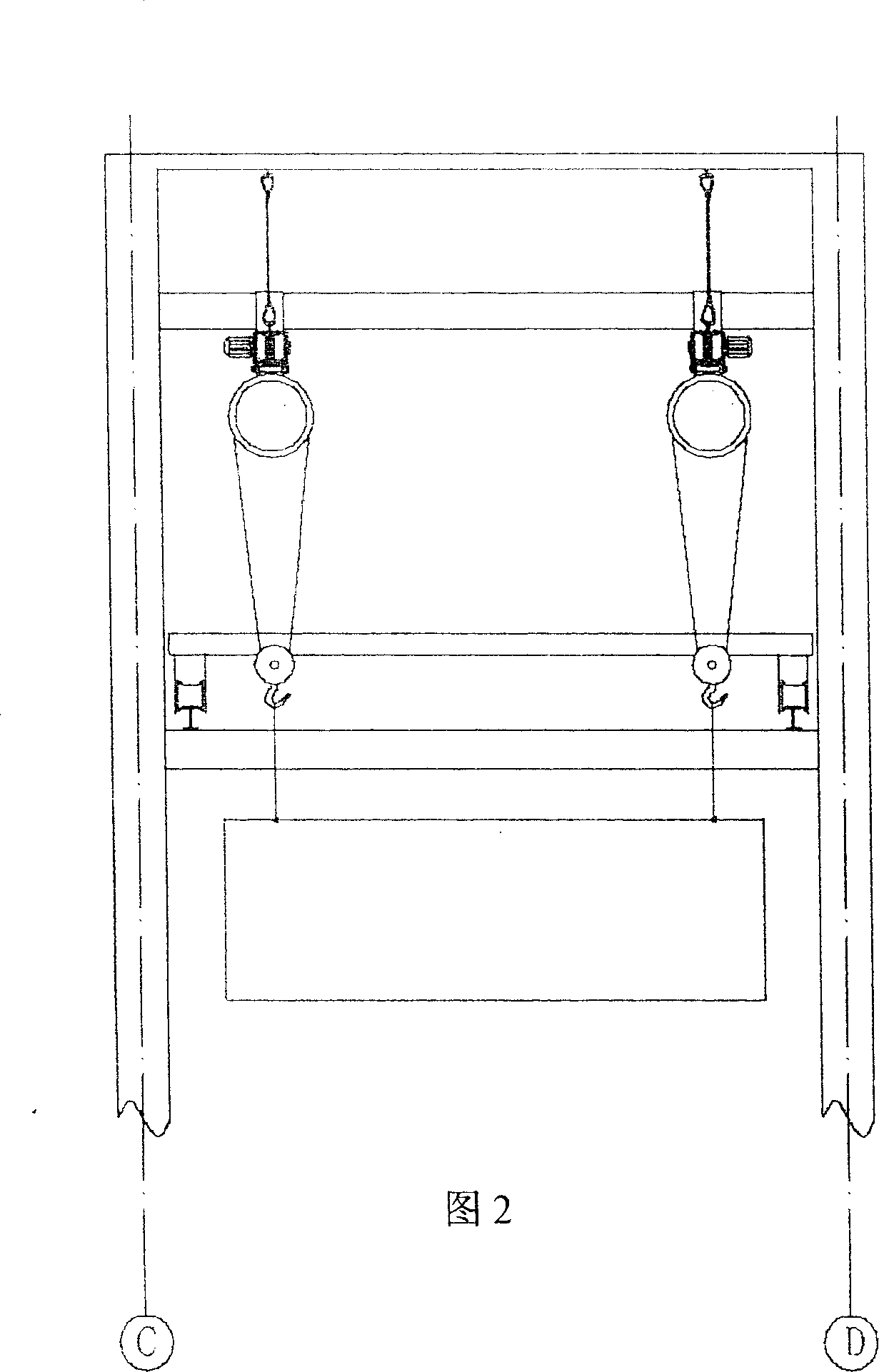

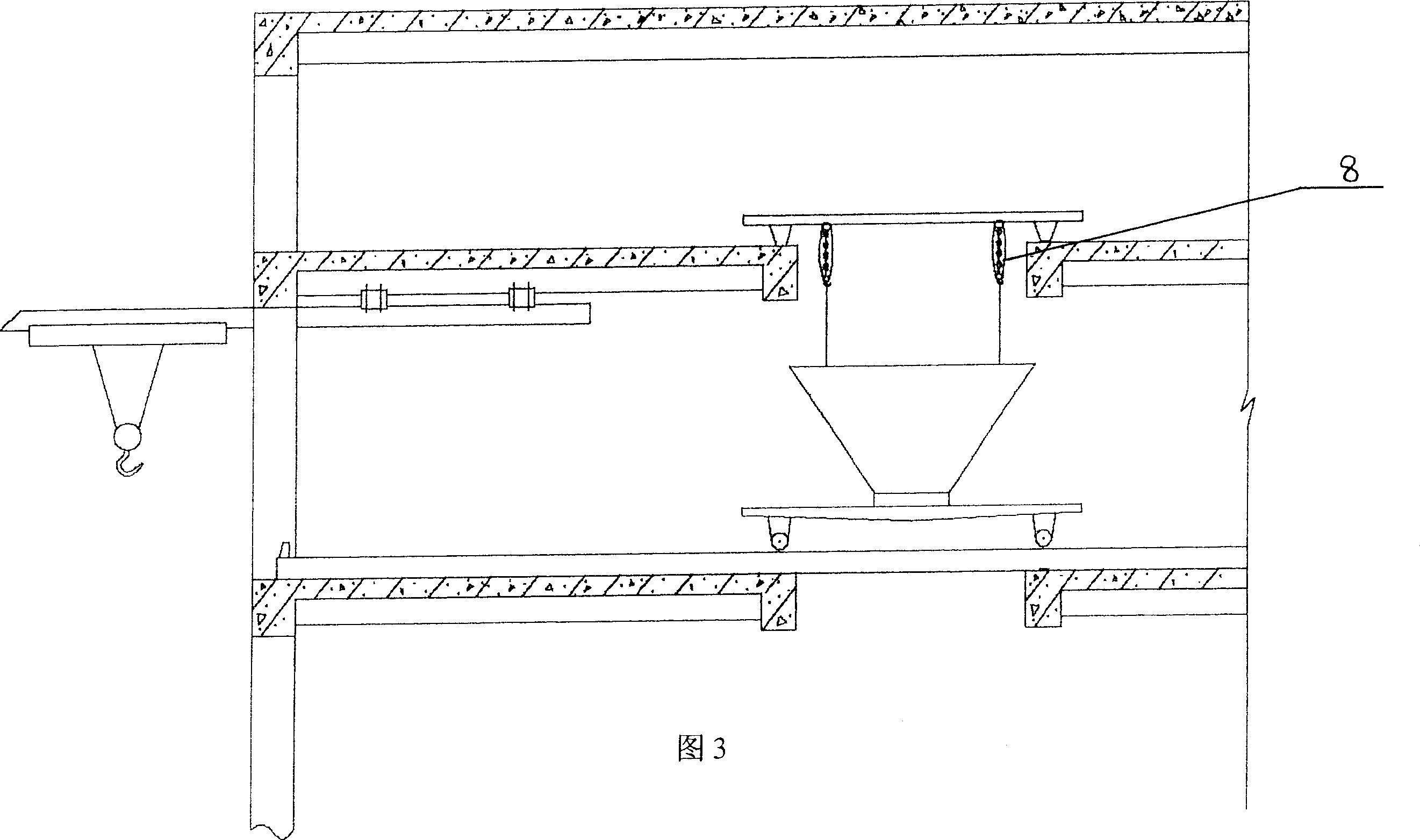

[0009] This embodiment is a specific implementation plan for newly-built 2×300MW units in a thermal power plant and supporting steel coal buckets. Referring to the accompanying drawings, two parallel cantilever tracks 4 made of 32# I-steel are fixed on the lower edge of the roof steel girder on the 22-meter layer of the C-D axis between the deoxygenated coal bunkers of the power plant. The cantilever track The cantilever of 4 stretches out of the factory building, and is fixed with the upper factory building by drag cables 2, and a 10-ton electric hoist 1 with a lifting height of 30 meters is suspended on each track 4; A pair of trolley walking track 6, on which a trolley 5 can be horizontally moved along the track 6 is set; the steel coal hopper 7 has a single weight of 47 tons, and is made in 5 sections during production, and is made by the pallet truck according to the construction plan According to the determined installation procedure, each section is transported to the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com