Constant-temperature colored pavement cold repair material and preparation process thereof

A cold patching and coloring technology, applied in building insulation materials, building components, buildings, etc., can solve problems such as waste of resources, impact on traffic, pollution, etc., and achieve the effects of low production costs, long storage time, and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

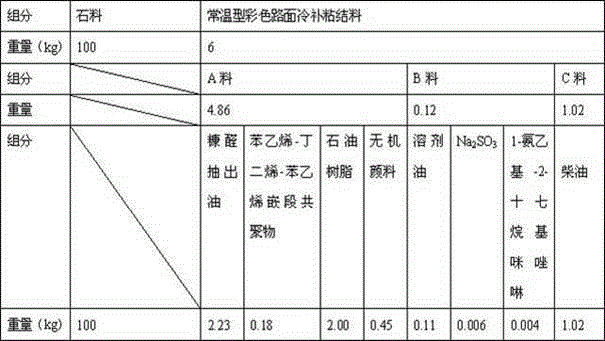

[0026] The raw materials used in the production of 106kg normal temperature colored pavement cold patch are as follows:

[0027]

[0028] Its preparation process is as follows:

[0029] ① Preparation of material A: first clean up the stirring equipment, and then add furfural extraction oil with a weight of 2.23kg, styrene-butadiene-styrene block copolymer with a weight of 0.18kg, and a weight of 2.00kg Petroleum resin with a weight of 0.45kg of inorganic pigments. During the addition process, the stirring equipment kept stirring, and the above mixture was heated to 170°C. After stirring at 170°C for 60 minutes, 4.86kg of cement was prepared by shearing A material;

[0030] ② Preparation of material B: mix 0.11kg of solvent oil and 0.006kg of Na 2 SO 3 1-aminoethyl-2-heptadecylimidazoline with a weight of 0.004 is mixed and stirred to make 0.12kg modified solution B material, as a lubricant and a modifier;

[0031] ③ First, heat 4.86kg of cementing material A prepared in...

Embodiment 2

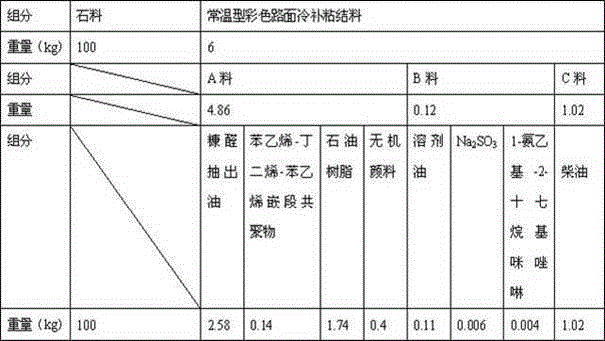

[0034] The raw materials used in the production of 106kg normal temperature colored pavement cold patch are as follows:

[0035]

[0036] Its preparation process is as follows:

[0037] ① Preparation of material A: first clean up the stirring equipment, then add furfural extract oil with a weight of 2.58kg, styrene-butadiene-styrene block copolymer with a weight of 0.14kg, and a weight of 1.74kg Petroleum resin with a weight of 0.4kg of inorganic pigments. During the addition process, the stirring equipment kept stirring, and the above mixture was heated to 170°C, and after stirring at 170°C for 60 minutes, 4.86kg of cement was prepared by shearing A material;

[0038] ② Preparation of material B: mix 0.11kg of solvent oil and 0.006kg of Na 2 SO 3 1-aminoethyl-2-heptadecylimidazoline with a weight of 0.004 is mixed and stirred to make 0.12kg modified solution B material, as a lubricant and a modifier;

[0039] ③First, heat 4.86kg of cementing material A prepared in step...

Embodiment 3

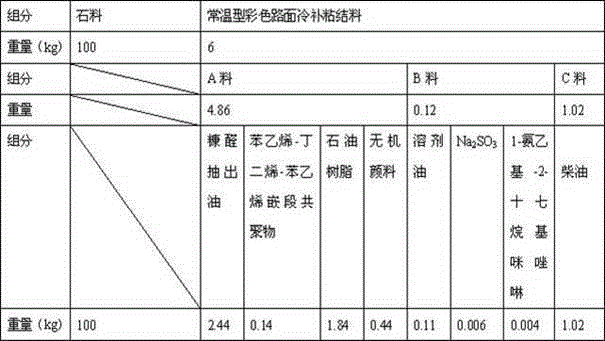

[0042] The raw materials used in the production of 106kg normal temperature colored pavement cold patch are as follows:

[0043]

[0044] Its preparation process is as follows:

[0045] ① Preparation of material A: first clean up the stirring equipment, then add furfural extract oil with a weight of 2.44kg, styrene-butadiene-styrene block copolymer with a weight of 0.14kg, and a weight of 1.84kg Petroleum resin with a weight of 0.44kg of inorganic pigments, the stirring equipment kept stirring during the addition process, and the above mixture was heated to 170°C, and after stirring at 170°C for 60 minutes, 4.86kg of cement was prepared by shearing A material;

[0046] ② Preparation of material B: mix 0.11kg of solvent oil and 0.006kg of Na 2 SO 3 1-aminoethyl-2-heptadecylimidazoline with a weight of 0.004 is mixed and stirred to make 0.12kg modified solution B material, as a lubricant and a modifier;

[0047] ③ First, heat 4.86kg of cementing material A prepared in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com