Three-dimensional fiber web composite plate structure

A fiber mesh and composite board technology, applied in building components, building structures, applications, etc., can solve the problems of inconvenient transportation and installation, cumbersome reinforced concrete components, and difficult construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

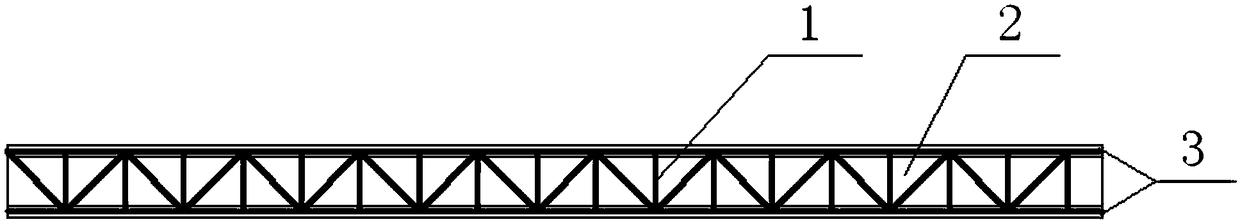

[0022] See attached figure 1 , the present invention provides a three-dimensional fiber net composite board with a single-layer three-dimensional fiber net body 1 and a single filler material 2 .

[0023] The size of the three-dimensional fiber mesh composite board is 1500×600×60mm, the thickness of the fiber three-dimensional mesh body is 50mm, and it is filled with C40 concrete.

[0024] The three-dimensional fiber mesh body 1 is made of alkali-resistant glass fiber, and the mesh in the layer is 30×30mm.

[0025] Make molds of composite dimensions with sufficient rigidity and surface finish. After the mold has passed the inspection, put in the trimmed three-dimensional fiber mesh body 1, and set a 5mm-thick cement block in a quincunx pattern with a distance of 300mm under the mesh.

[0026] The C40 concrete mixture that has been stirred is poured into the mold with the three-dimensional fiber mesh body 1, and evenly distributed, and the concrete mixture is vibrated and com...

Embodiment 2

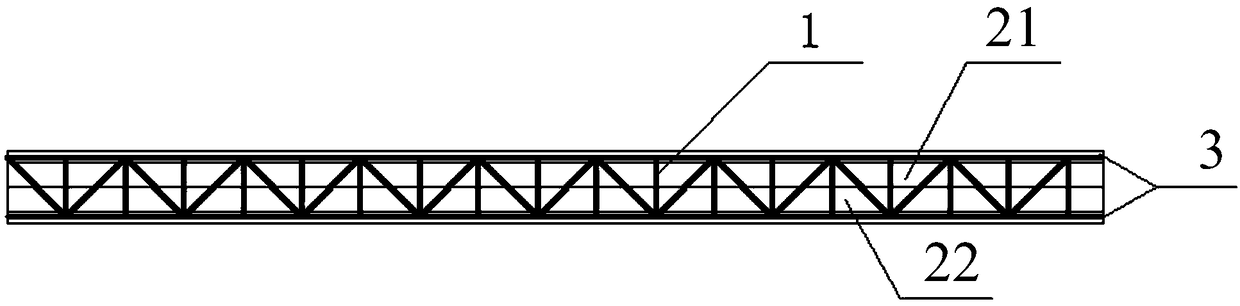

[0029] See attached figure 2 , the present invention provides a single-layer three-dimensional fiber mesh body 1 and two kinds of fillers 2 three-dimensional fiber mesh composite board.

[0030] The size of the three-dimensional fiber mesh composite board is 1500×600×80mm, the thickness of the fiber three-dimensional mesh body 1 is 70mm, and it is filled with C40 concrete 21 and expanded perlite concrete 22 .

[0031] The three-dimensional fiber net body 1 is made of alkali-resistant glass fiber or woven with cotton-type medium-long fiber, and the mesh size in the layer is 40×40mm.

[0032] Make molds of composite dimensions with sufficient rigidity and surface finish. After the mold has passed the inspection, put in the cut three-dimensional fiber mesh body, and set a 5mm thick cement block in a plum blossom pattern with a distance of 300mm under the mesh.

[0033] Pour the stirred C40 concrete 21 mixture into the mold with the three-dimensional fiber mesh body 1, the pour...

Embodiment 3

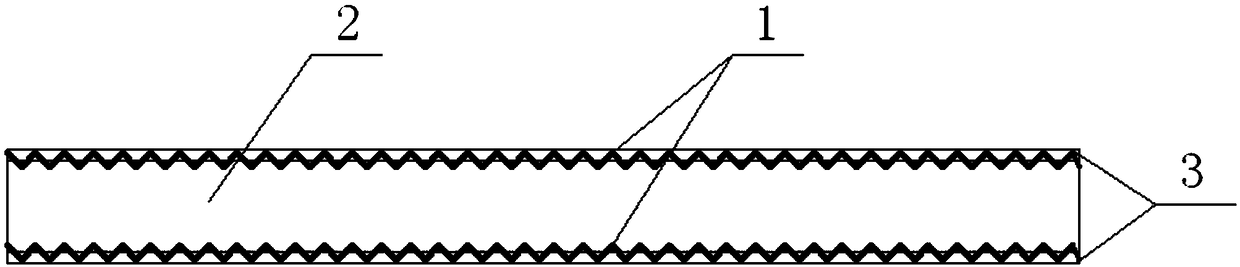

[0036] See attached image 3 , the present invention provides a three-dimensional fiber net composite board with a double-layer three-dimensional fiber net body 1 and a single filler material 2 .

[0037] The size of the three-dimensional fiber net composite board is 1500×600×100mm, the thickness of the three-dimensional fiber net is 10mm, and the foamed concrete 22 with a filling density of 300Kg / m3.

[0038] The three-dimensional fiber mesh body 1 is made of alkali-resistant glass fiber or woven with cotton-type medium-long fiber, and the mesh size in the layer is 15×15mm.

[0039] Make molds of composite dimensions with sufficient rigidity and surface finish. After the mold has passed the inspection, put in two layers of cut three-dimensional fiber nets, and set supports between the two layers of nets and between the nets and the mold surface to ensure that the distance between the two layers of nets is 70mm and the distance between the net surface and the mold surface is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com