Multi-dimensional vibration isolation and damping device with multi-directional anti-drawing and pre-tightening functions and vibration isolation and damping method thereof

A pre-tightening and pull-out technology, applied in building components, building types, earthquake-proof, etc., can solve the problem of inability to observe changes in device performance in real time, poor vertical pull-out and torque performance, and multi-dimensional vibration isolation and torsional effects. It can achieve the effect of clear force transmission and energy consumption mechanism, enhanced overall deformation ability, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

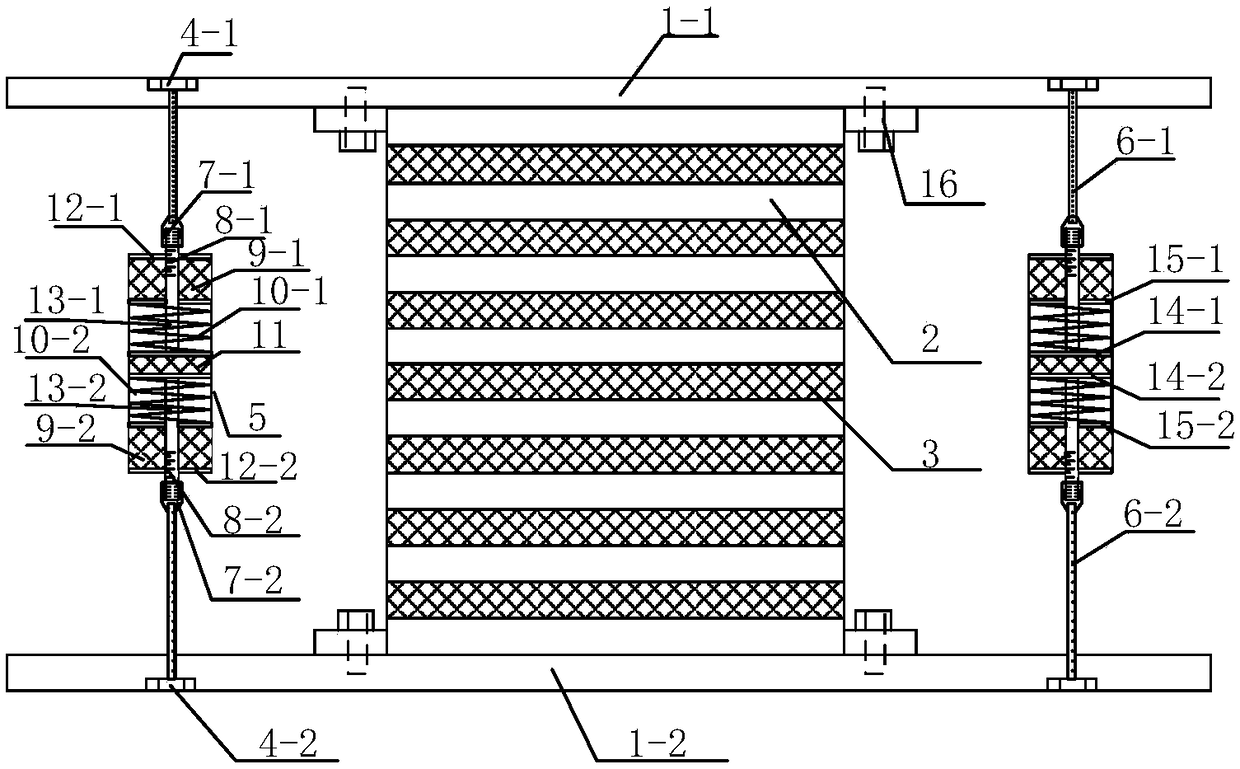

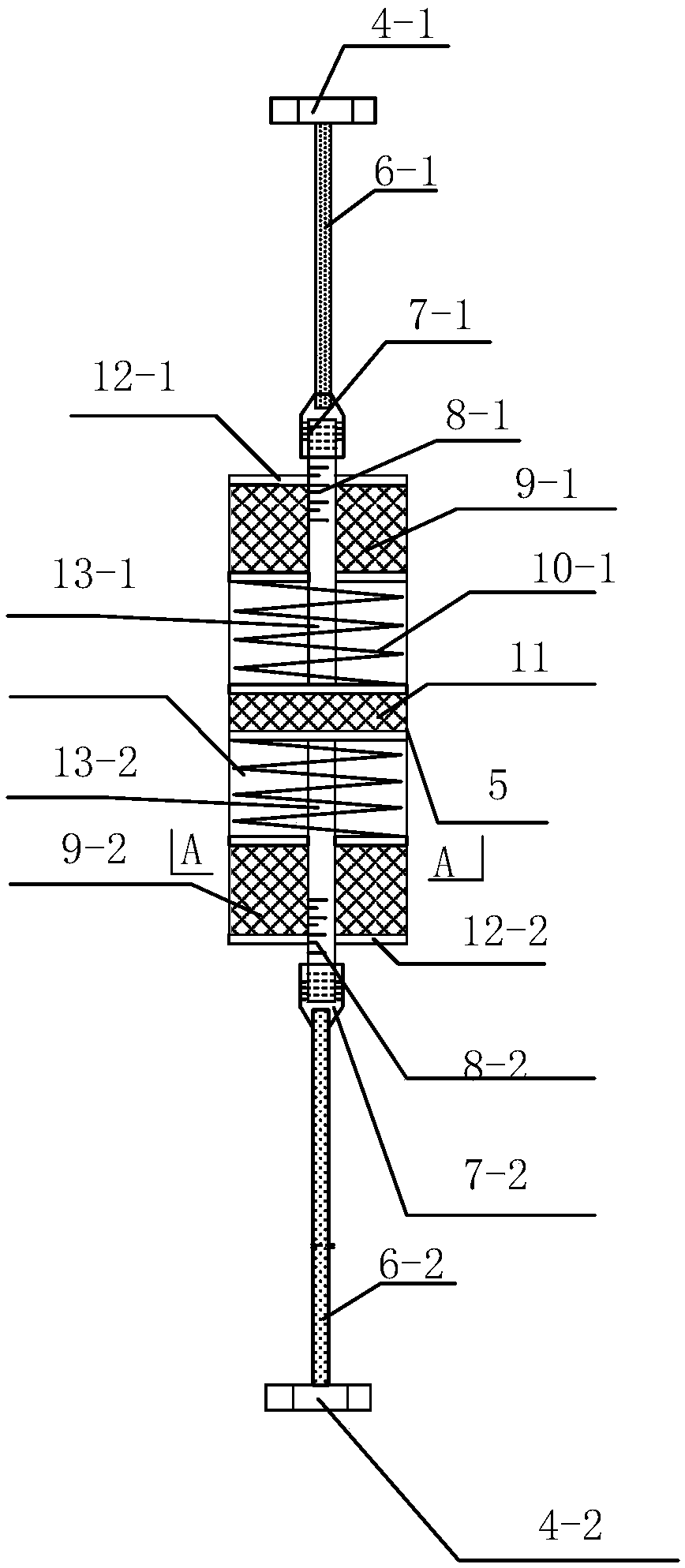

[0050] The preloaded cylindrical damper 5 is located between the upper and lower pressure steel plates, and a total of four preloaded cylindrical dampers are used, which are symmetrically and evenly installed around the core damping pad.

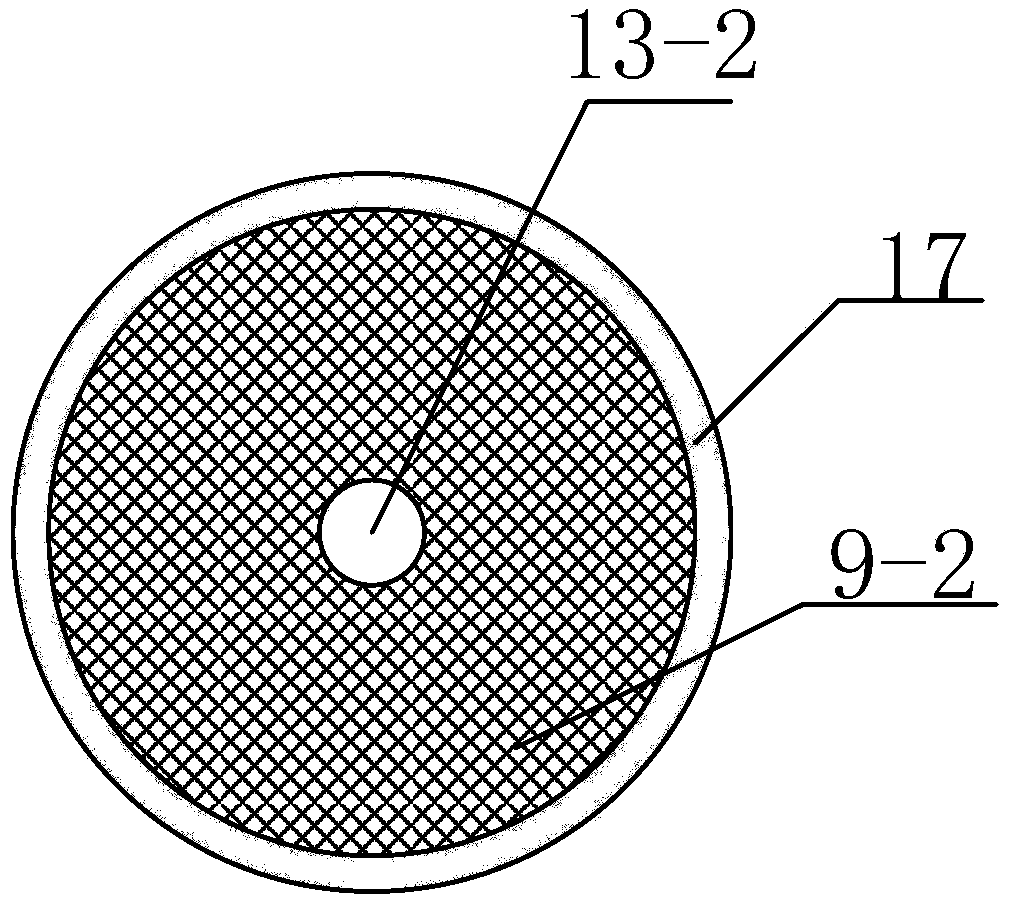

[0051] The core damping pad steel plate layer 2 and the viscoelastic material layer 3 of the core damping pad are laminated at intervals in sequence, and vulcanized under high temperature and high pressure to form a core damping pad (that is, the arrangement rule of the viscoelastic material and the steel plate is the layout of the interlayer, similar to In the "sandwich" structure.) It is also located between the upper and lower pressure steel plates, and installed at the center of the upper and lower pressure steel plates. Among them, the preloaded cylindrical damper 5 is mainly used to weaken the vibration effect in the vertical direction, and the preloaded force is provided by the preloaded spring 10, so that it can bear a large pulling f...

Embodiment 2

[0075] In this embodiment, the viscoelastic material in the preloaded cylindrical damper 5 is replaced with aluminum foam.

Embodiment 3

[0077] In this embodiment, the viscoelastic material layer 3 of the core damping pad is replaced by rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com