Mechanical sand prevention method for small sleeve producing well, mechanical sand prevention tubular column and fishing tool

A technology for fishing tools and sand control pipes, which is applied in the direction of casing, drilling pipes, and mining fluids. It can solve problems such as unsatisfactory requirements for unblocking and unloading karaage, failure to salvage, thread damage, etc., and achieve good use effects and application prospects. , improve the success rate of downhole, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings, without limiting the protection scope of the present invention. The following descriptions are only preferred embodiments of the present invention, and other equivalent changes using the present invention shall fall within the protection scope of the present invention.

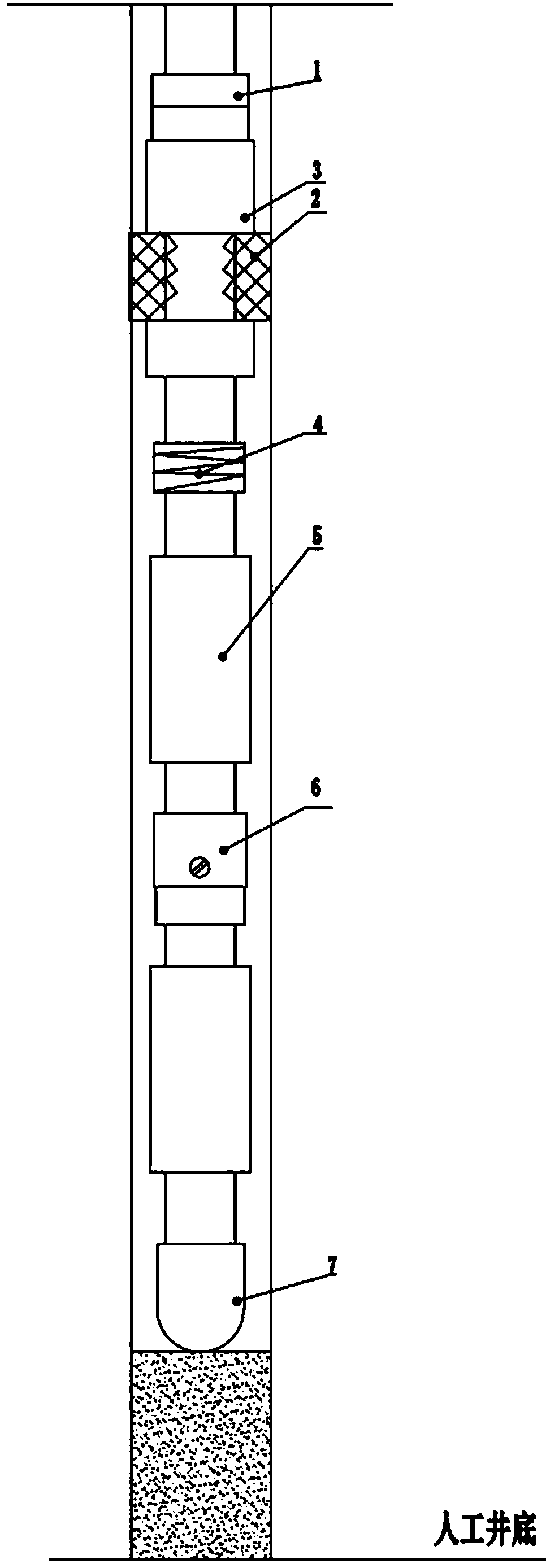

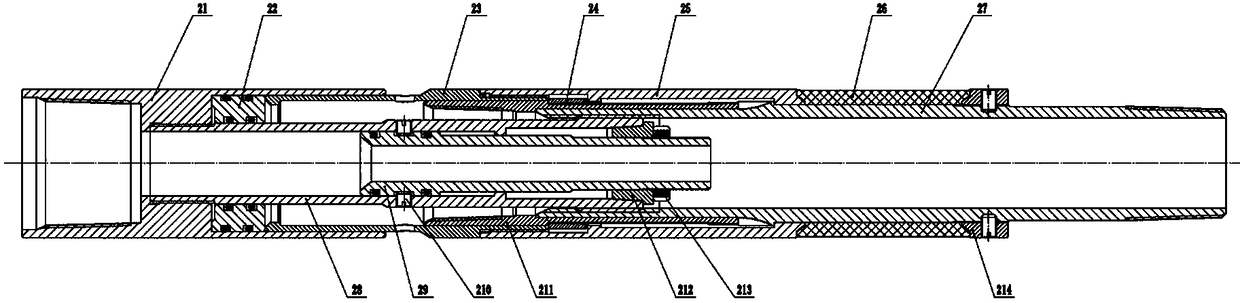

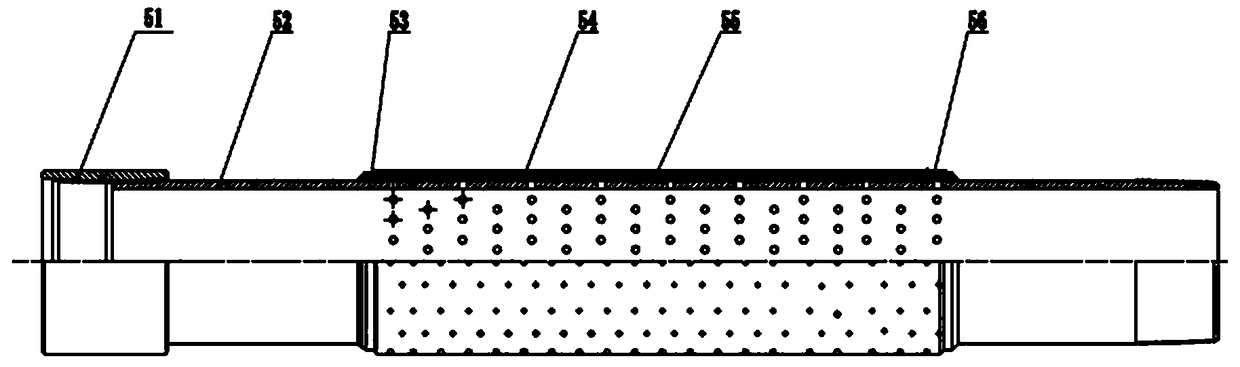

[0021] see figure 1 and figure 2 , the mechanical sand control method for small casing oil production wells is: connect a packer 2 with the function of dropping hands in the mechanical sand control string, the packer 2 does not have a slip support mechanism and slips, and passes through the bottom of the mechanical sand control string It leans against the sand surface of the artificial well bottom and throws the ball into the packer 2 to provide tension for the pressure seat seal of the rubber tube 26. The mechanical sand control string can be released through liquid pressure and mechanical undercut....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com