Optical fiber temperature sensor based on surface plasmon resonance and strain compensation

A surface plasmon and strain compensation technology, applied to thermometers, thermometers, instruments, etc. that change physically/chemically, can solve problems such as deviation of temperature measurement results, influence on resonance wavelength, and inability to eliminate the influence of strain, making it less susceptible and less prone to Effects of Electromagnetic Interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the specific structure, principle and working process of the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

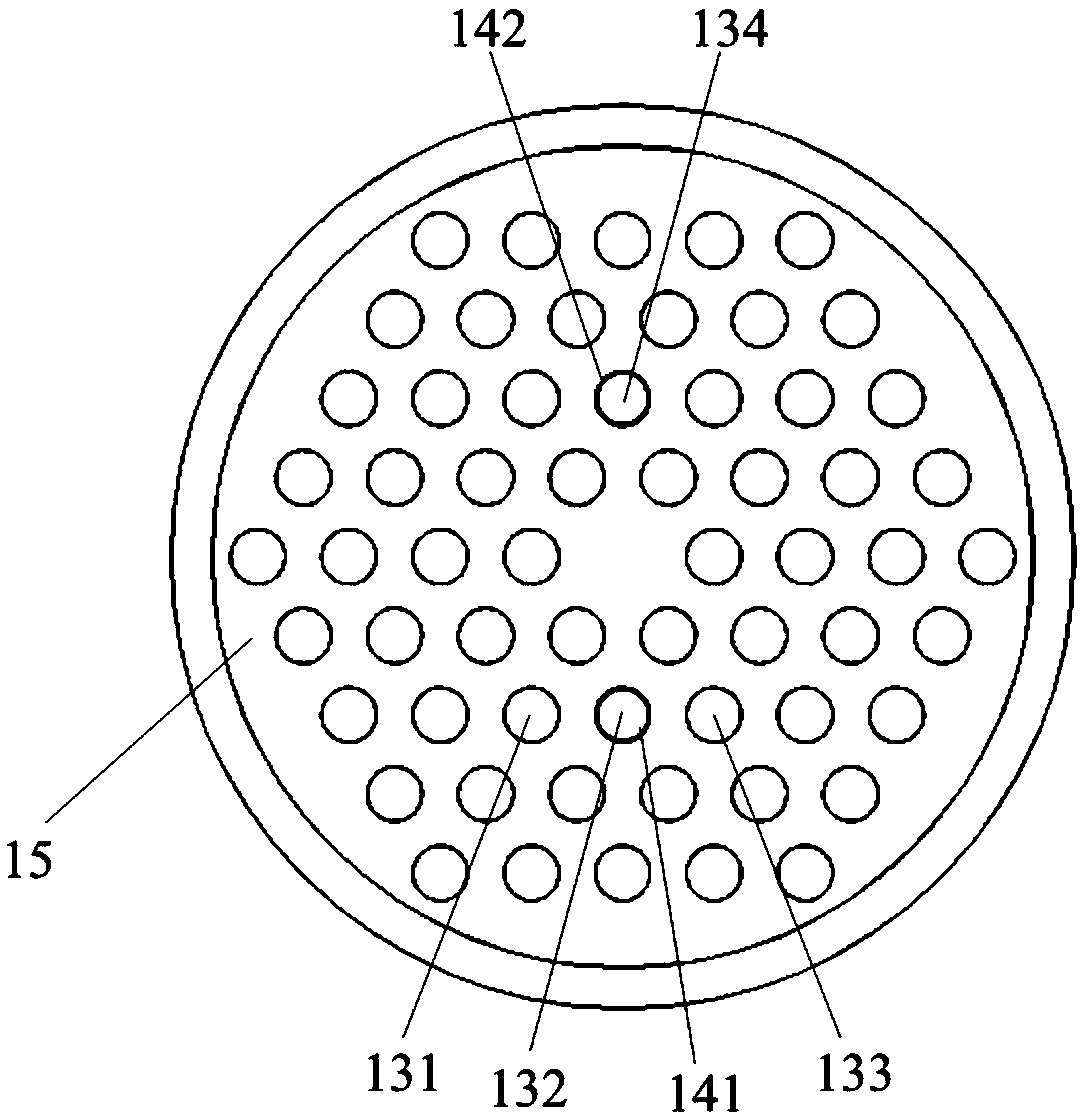

[0024] Such as figure 1 Shown is the structural diagram of the optical fiber temperature sensor based on surface plasmon resonance and strain compensation proposed by the present invention. The optical fiber temperature sensor based on surface plasmon resonance and strain compensation is composed of a protective sleeve 11 and a sensing optical fiber 12 . The protective sleeve 11 has an outer diameter of 1mm and is made of quartz material, and is used to protect the sensing optical fiber from damage such as breakage caused by the environment under test. Such as figure 2 A structural diagram of the sensing fiber 12 is shown. Sensing optical fiber 12 is made up of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com