Automatic sampling device of new-type oil storage tank

An automatic sampling device and oil storage tank technology, applied in sampling devices, sampling, measuring devices, etc., can solve the problems of high labor intensity, affected sample quality, oil leakage to the top of the oil tank, etc., to reduce the labor of workers. The effect of strength, sampling work saving time and effort, and convenient sampling operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

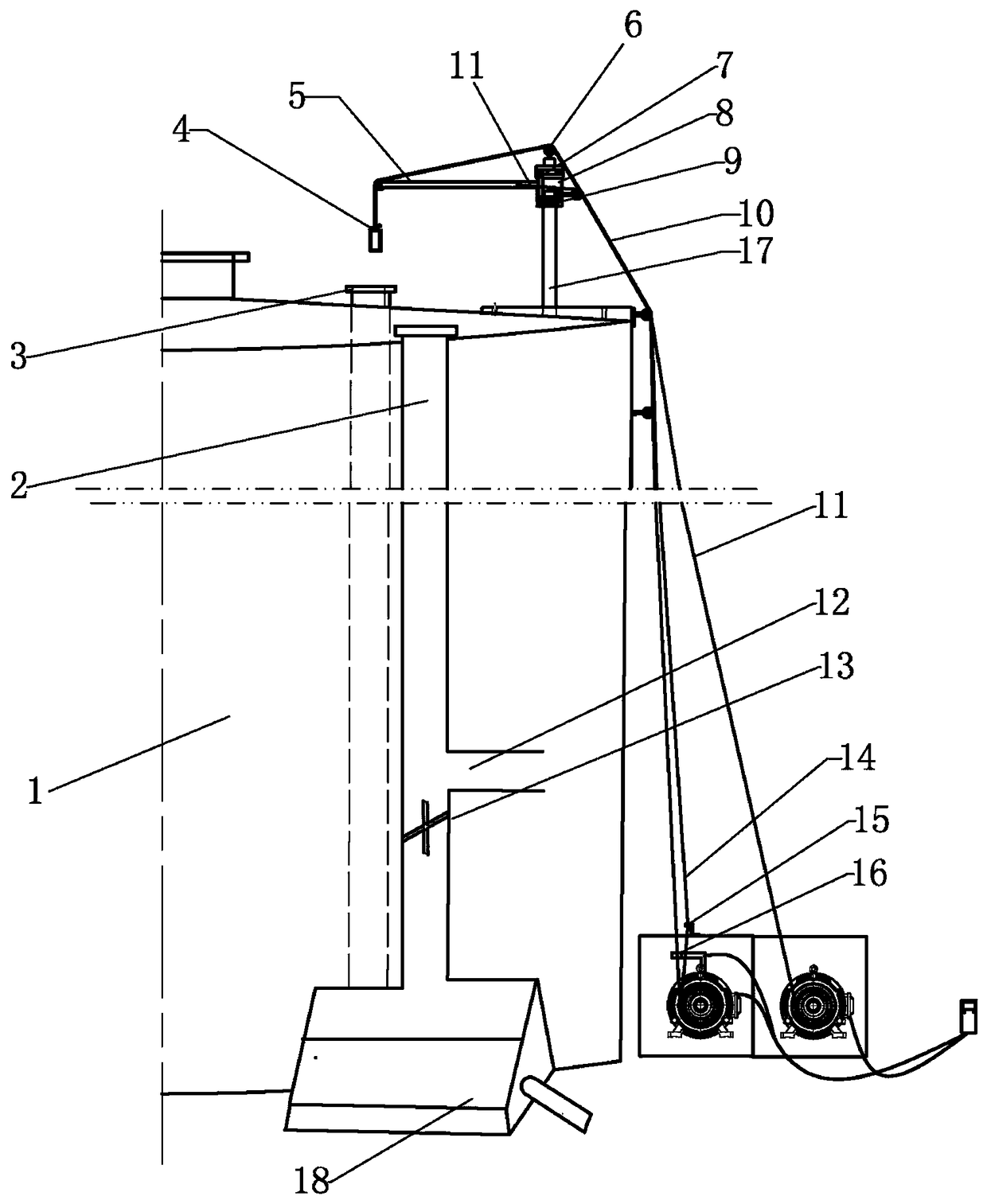

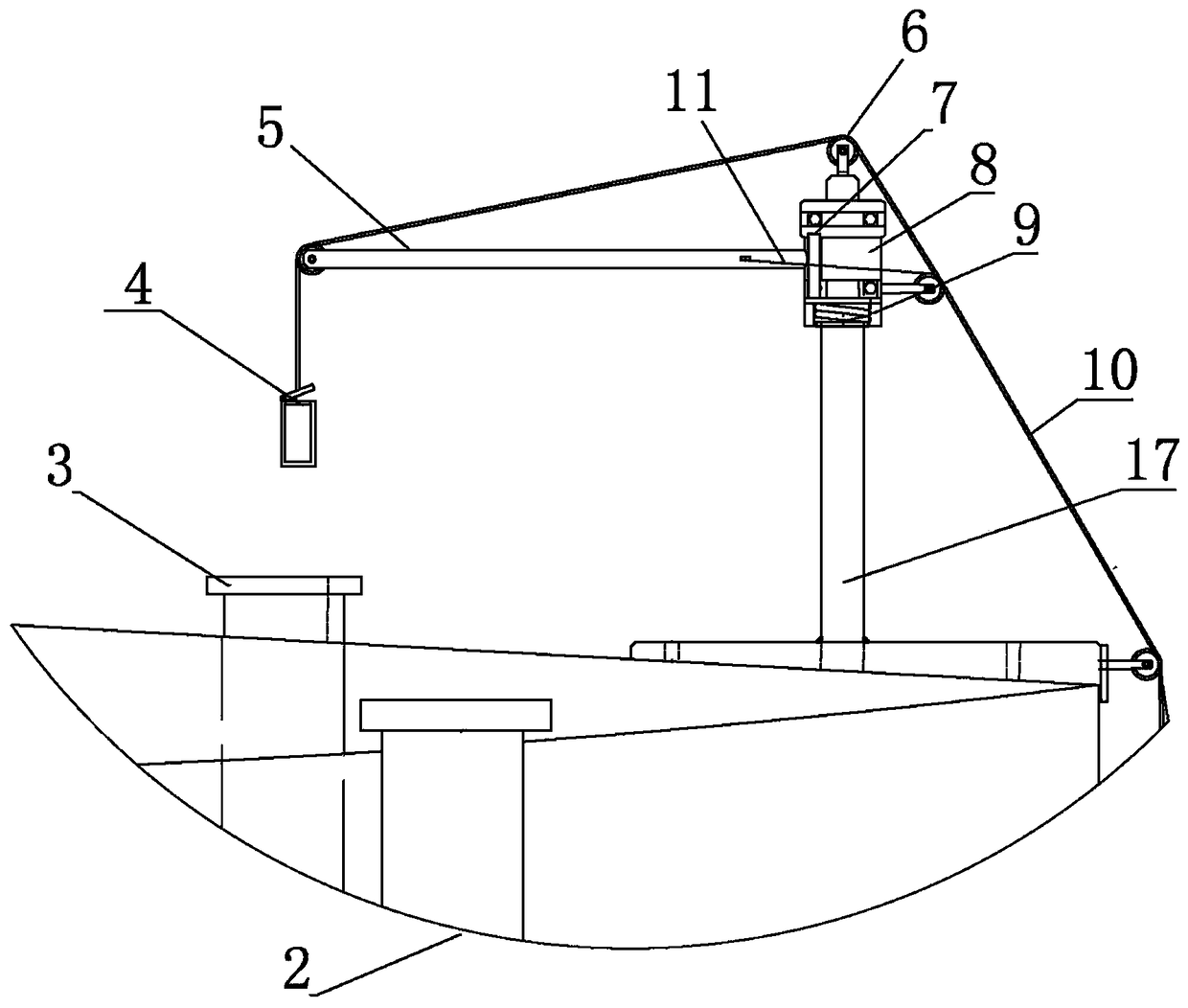

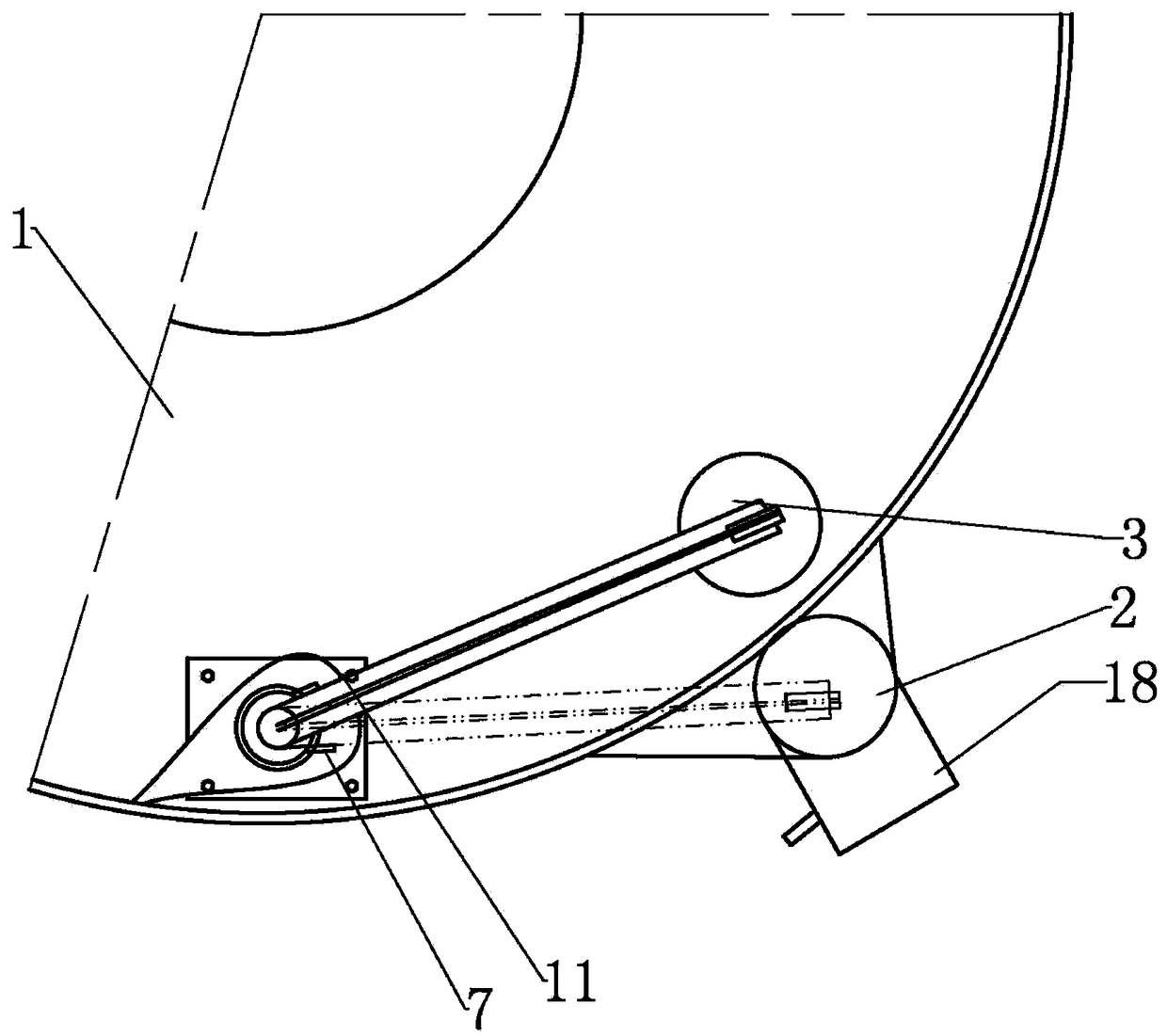

[0011] A new type of automatic sampling device for oil storage tanks, such as figure 1 , figure 2 , image 3 As shown, including frame column 17, meter counter 16, three steel wire ropes and two motors, frame column 17 is vertically installed on the top surface of oil tank 1 by mounting seat. A T-shaped swing arm 5 is installed on the top of the frame column 17 through horizontally arranged bearings, and one end of the swing arm 5 is provided with two fixed pulleys. The other end of the swing arm forms a vertically arranged rotating shaft 8, a reset torsion spring 9 is set on the lower end of the rotating shaft 8, a bearing is also arranged on the top of the rotating shaft, and a double groove fixed pulley 6 is installed on the top of the rotating shaft through the bearing. A swing arm limit plate 7 is respectively arranged on both sides of the 17 top, and a swing arm stay rope 11 is connected on the side wall of the swing arm. The drum is connected; the motor 20 drum rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com