Bolt strength detection device

A strength detection and bolt technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of rapid detection of unfavorable batch workpieces, low work efficiency, easy tilting of workpieces, etc., to achieve a stable and reliable detection process and reduce labor. Strength, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

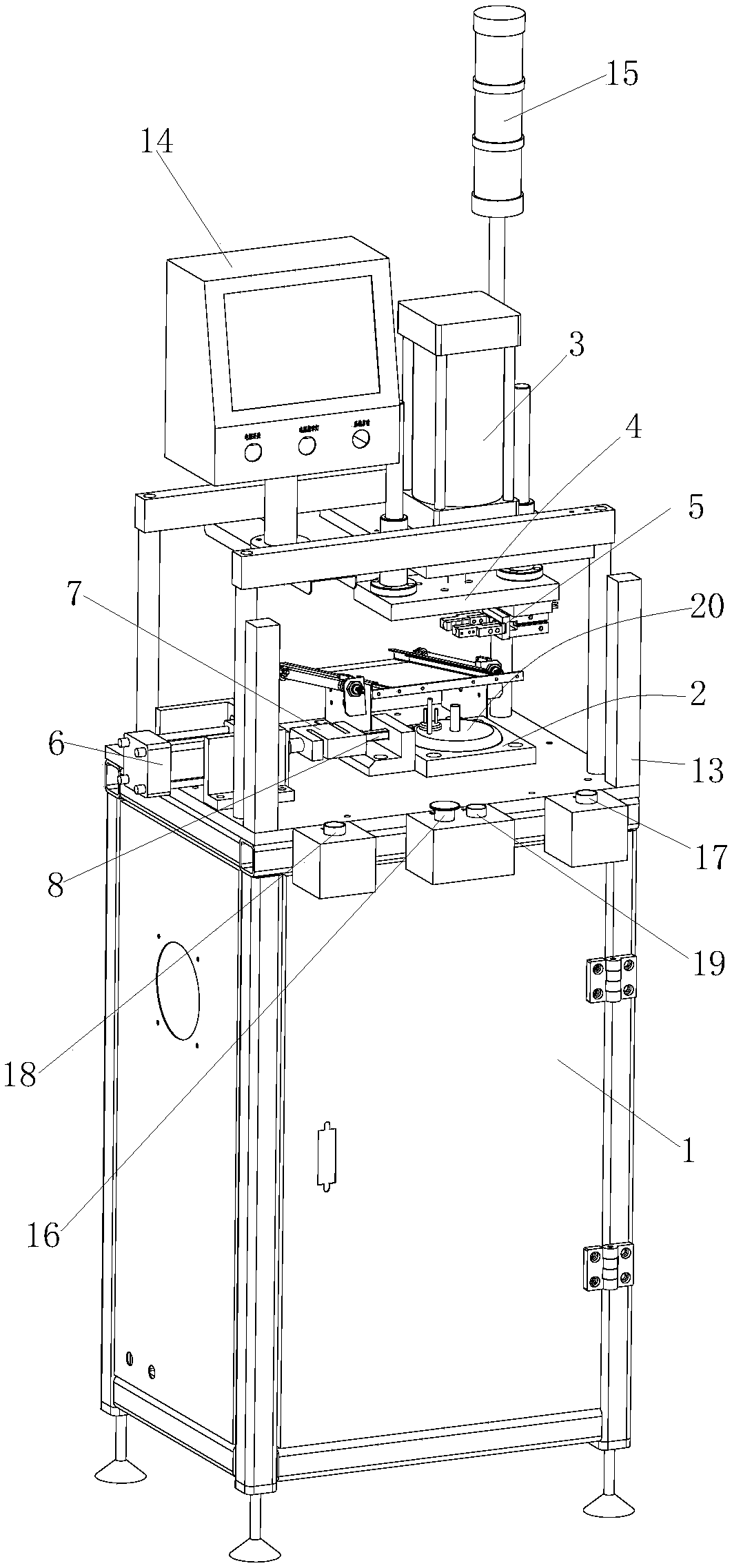

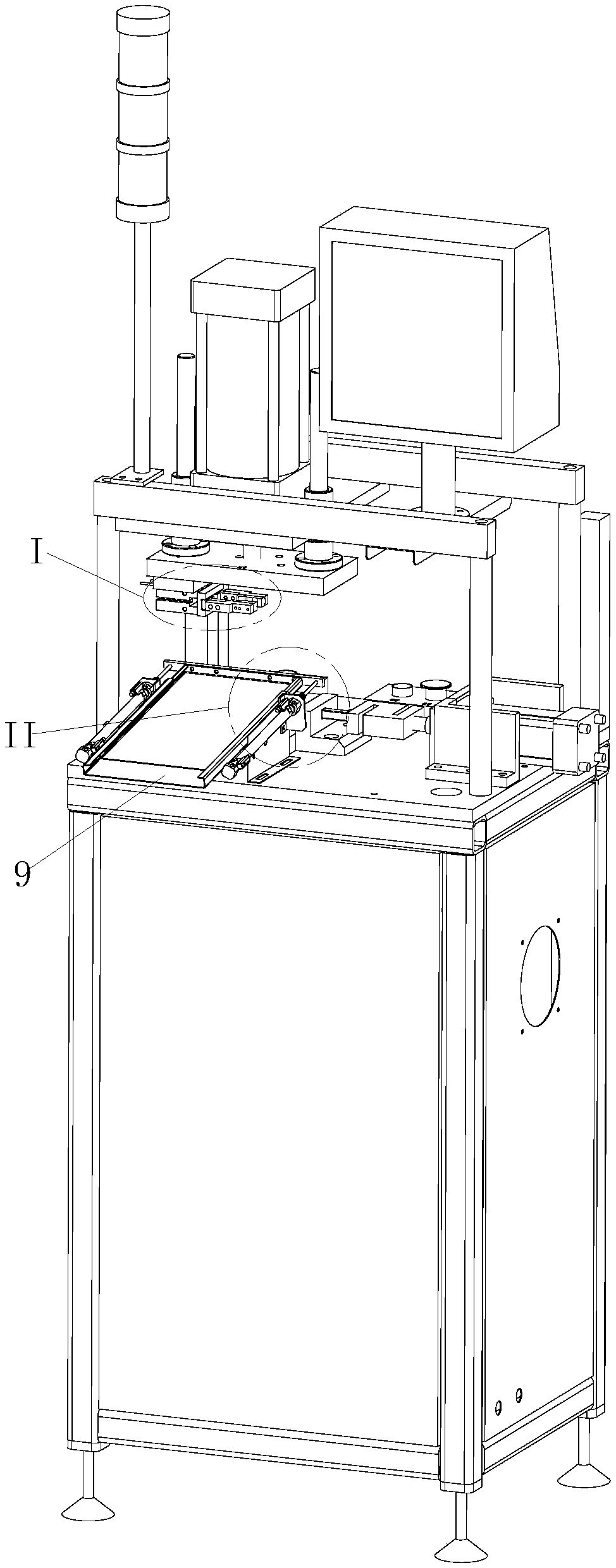

[0026] Such as Figure 1 to Figure 5 As shown, a bolt strength detection device includes a cabinet 1, a positioning platform 2 fixed on the cabinet 1, and also includes:

[0027] The pressing mechanism is connected to the top of the cabinet 1 and vertically presses the workpiece 20 on the positioning table 2 after clamping it.

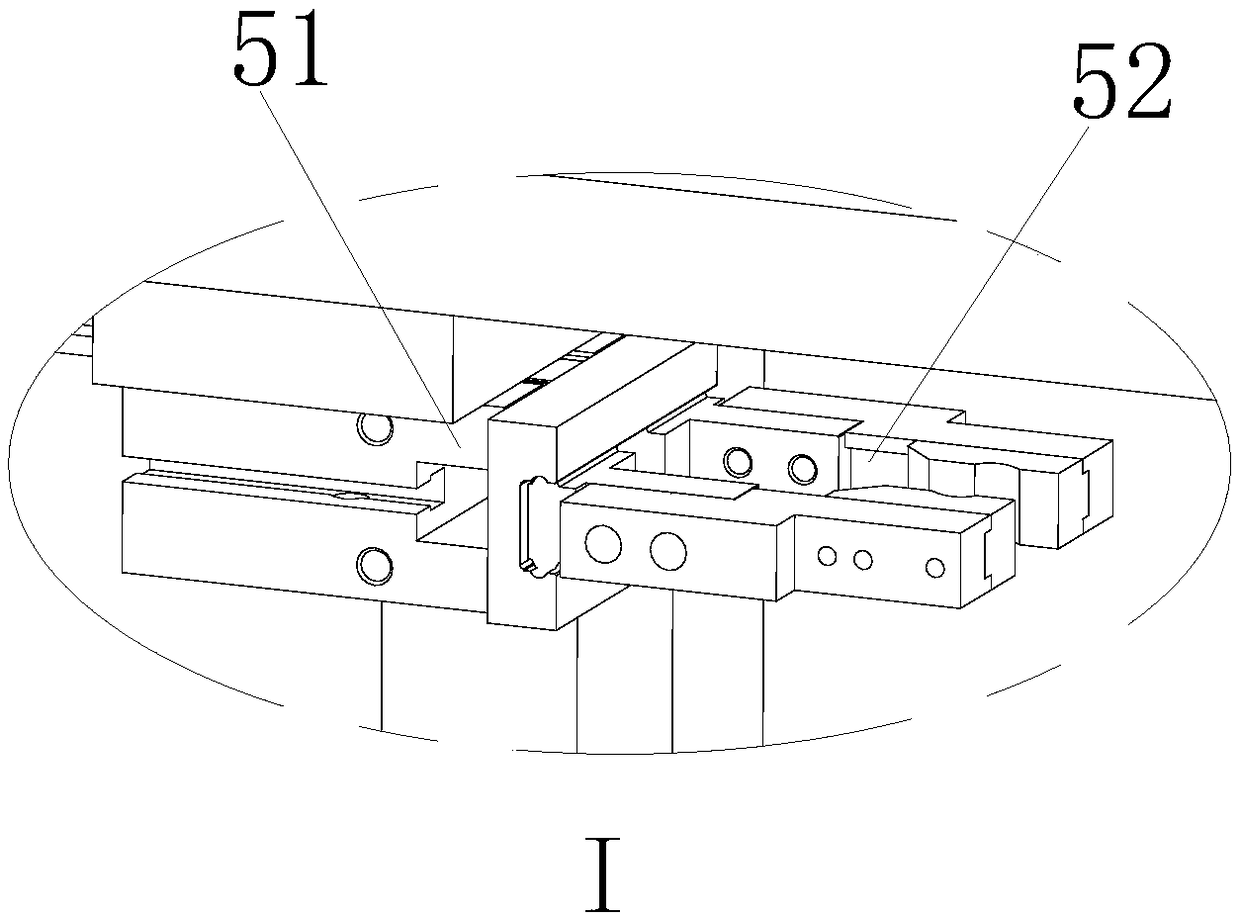

[0028] The detection mechanism is fixed on the left side of the cabinet 1 and laterally pushes the welding bolts 20a on the workpiece 20 to read test data.

[0029] The unloading mechanism is installed on the rear side of the cabinet 1 and can move to the bottom of the pressing mechanism to take away the detected workpiece 20 .

[0030] The man-machine interface 14 is fixed on the top of the cabinet 1 and connected with the detection mechanism for displaying d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com