Motor

A stator and housing technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of unstable motor operation, reduced motor service life, deformation of motor structural parts, etc., to improve heat transfer effect and excellent motor performance , fast warm-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

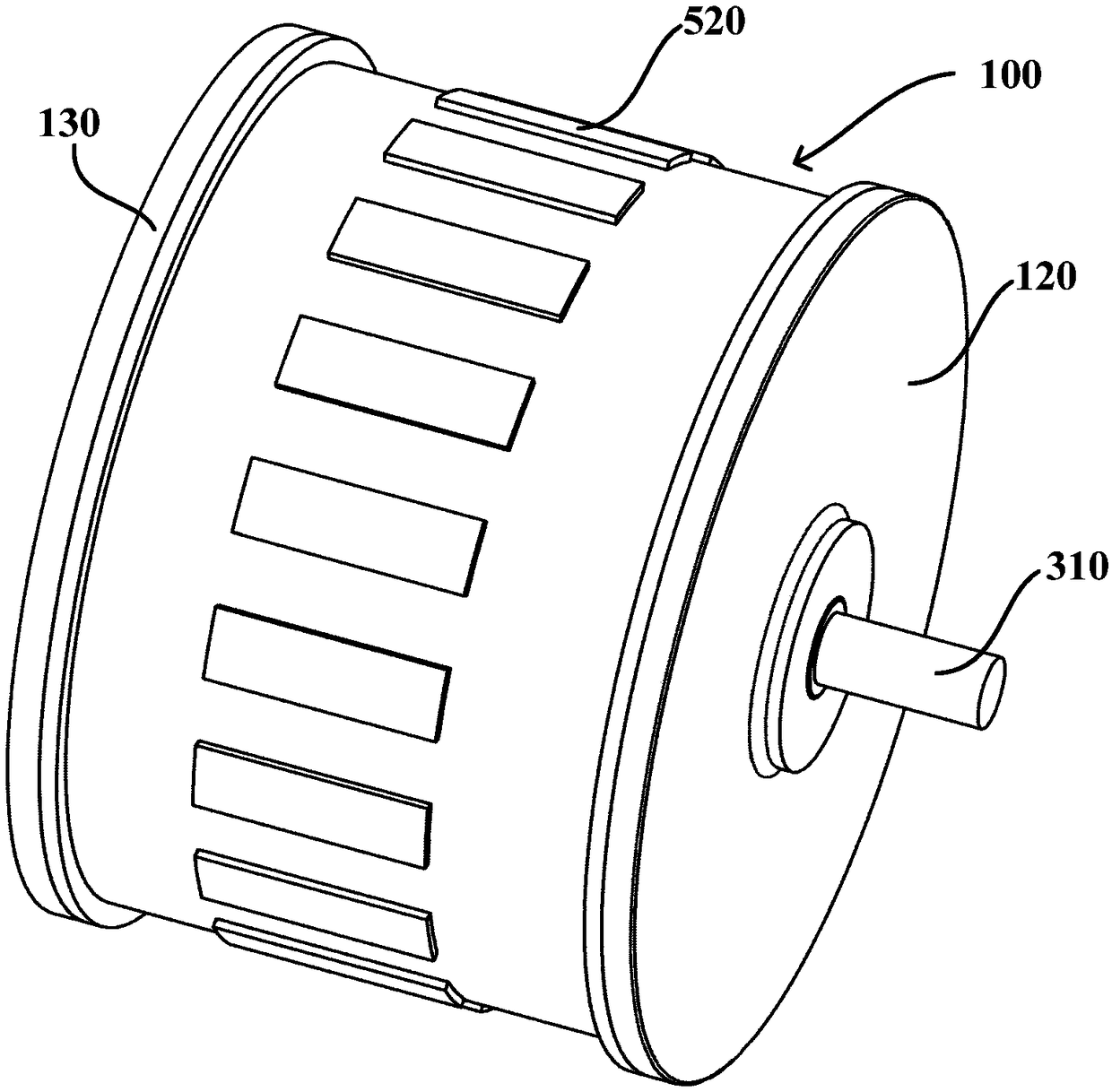

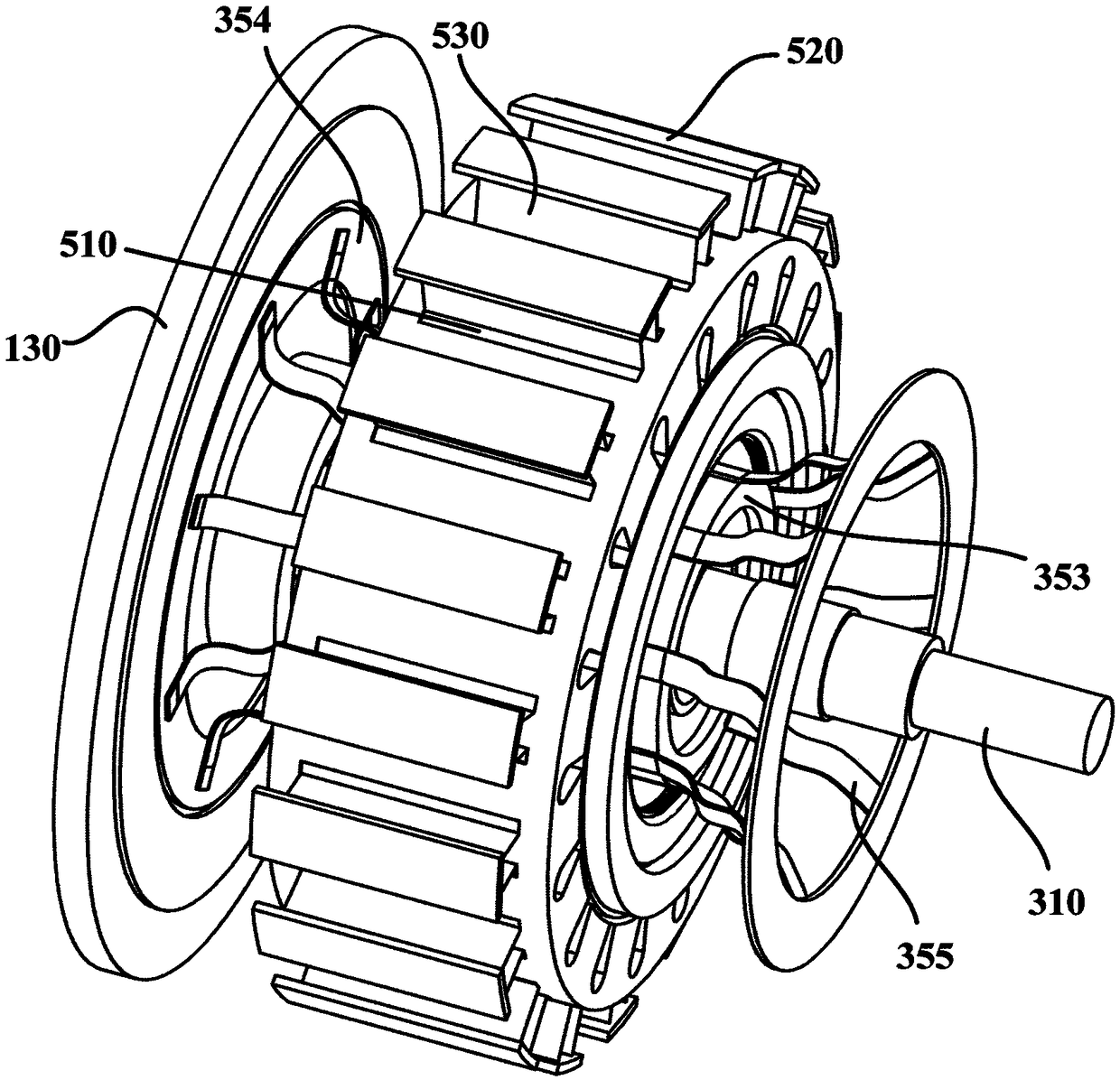

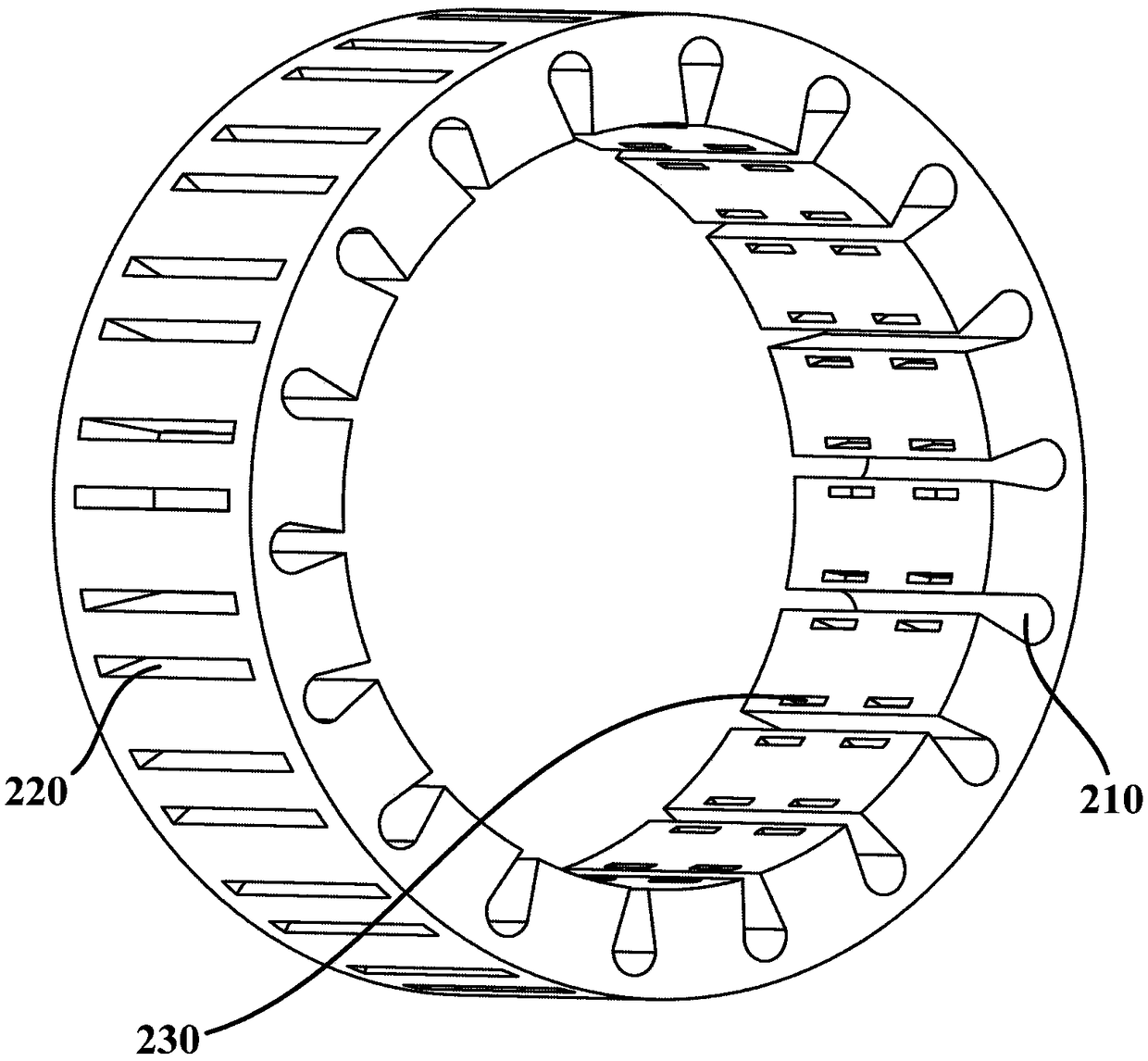

[0045] figure 1 is a schematic structural diagram of a motor according to an embodiment of the present invention. Such as figure 1 shown, and refer to figure 2 and image 3 , the embodiment of the present invention provides a motor. Generally, the motor may include a housing 100 , a stator 200 and a rotor 300 . The housing 100 generally has a main housing 110 and end covers disposed on two ends of the main housing 110 , such as a housing front cover 120 and a housing rear end cover 130 . The stator 200 is disposed in the housing 100 . The rotor 300 is disposed radially inside the stator 200 . The iron core of the stator 200 has stator slots 210 for winding windings 240 .

[0046]In particular, the stator core also has a plurality of heat transfer through holes. Each heat transfer through hole includes a first strip-shaped hole 220 opening toward the radially outer side of the stator, and a plurality of rectangular oil holes 230 opening toward the radially inner side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com