Granary and method capable of effectively repelling insects

A granary and grain technology, applied in the field of granary, can solve problems affecting people's health and environmental pollution, and achieve the effect of ensuring physical health, avoiding environmental pollution, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

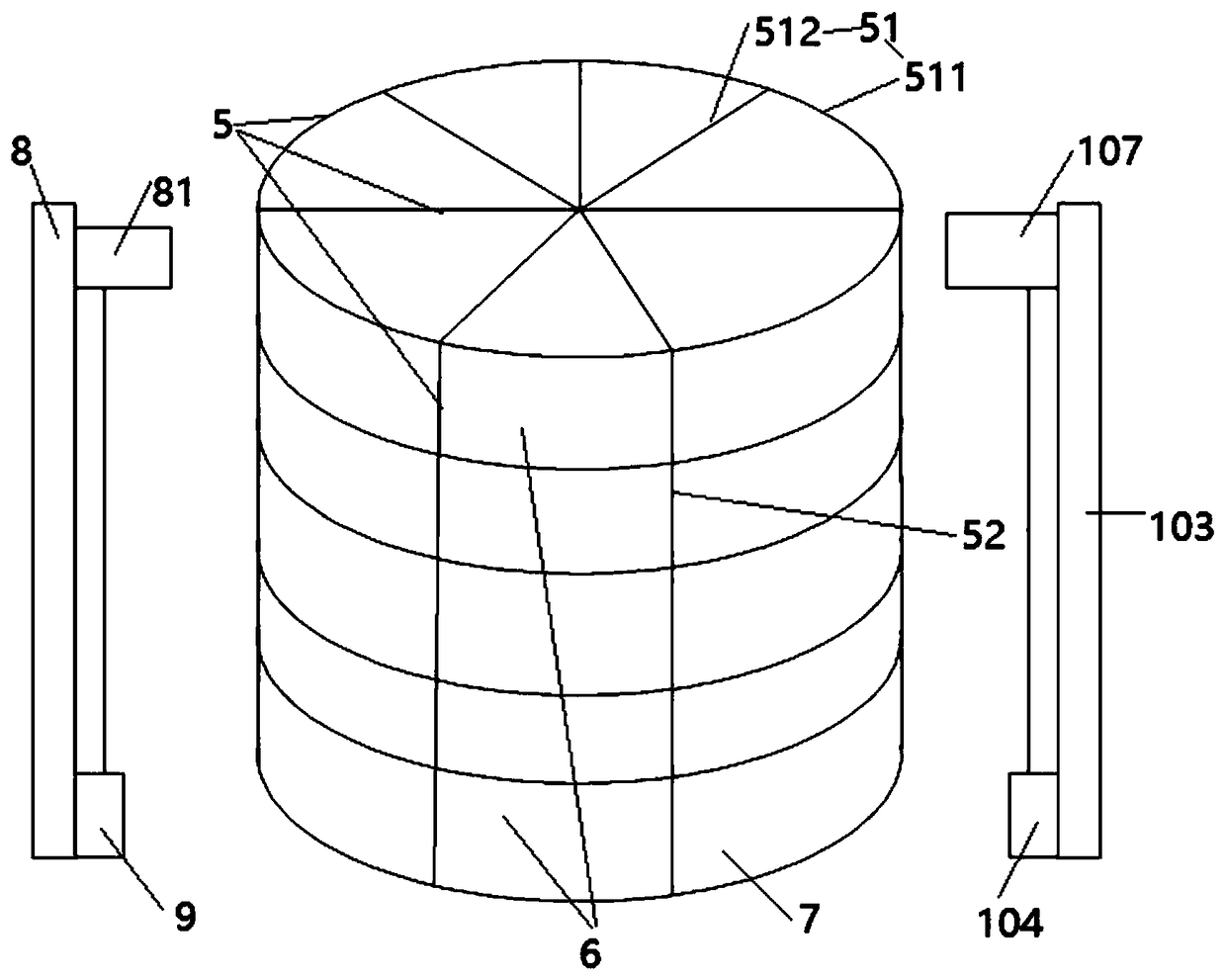

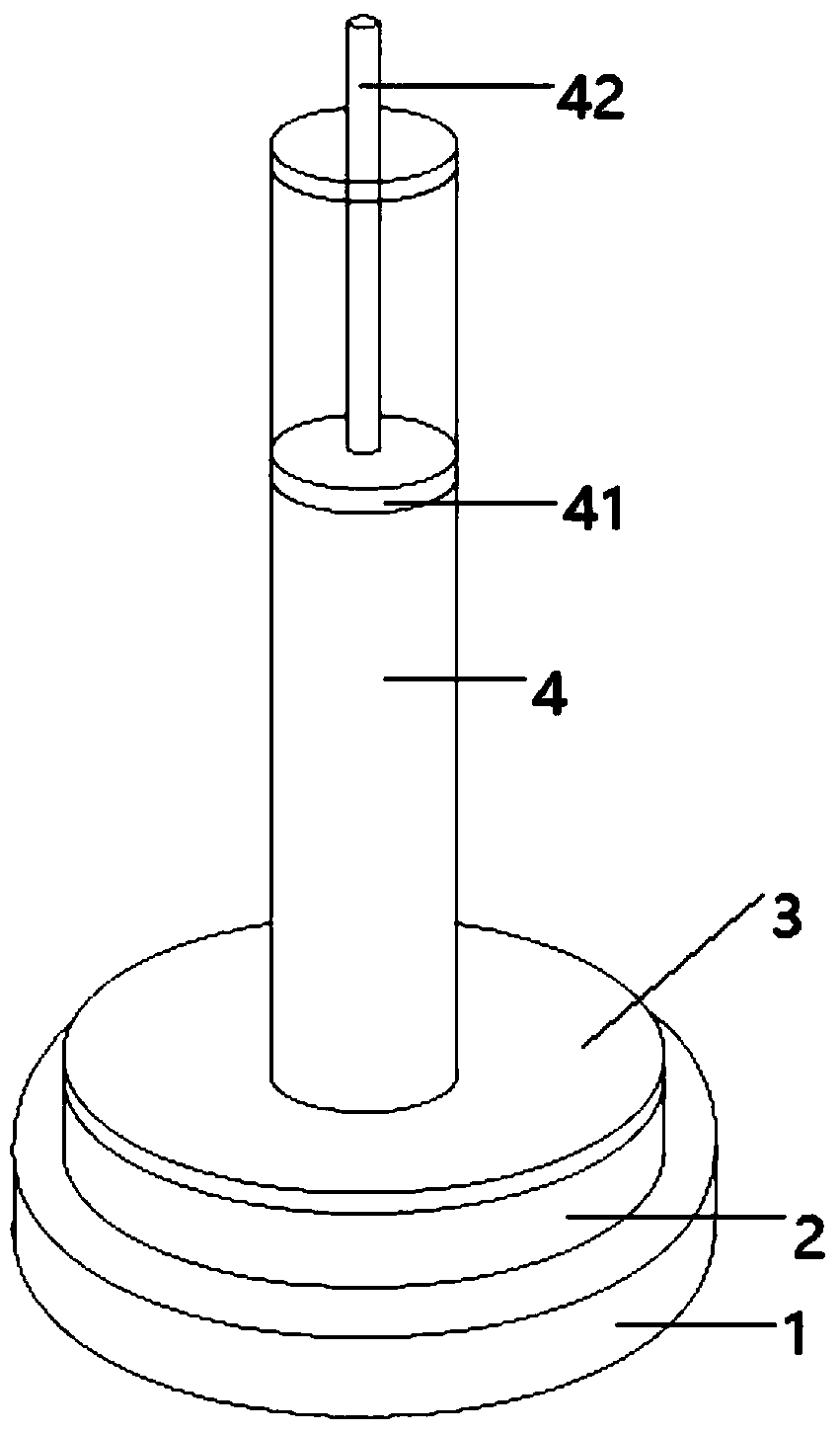

[0036] Such as figure 1 The shown embodiment 1 of a granary that can effectively repel insects includes a base 1, a horizontally stretched air bag 2 arranged on the base, a pressure plate 3 arranged on the air bag, and a vertical tube 4 with an open lower end arranged in the center of the pressure plate , the push plate 41 that is located in the vertical tube, the vertical bar 42 that is located on the push plate and stretches out from the upper end of the vertical tube, the support frame 5 connected with the vertical bar upper end, and the telescopic coaming plate 6 that is located on the outside of the support frame; The bracing frame comprises a horizontal support 51 and 7 vertical pipes 52 connected to the outer edge of the horizontal support. Each vertical pipe is a casing structure. The standpipe is fixedly connected, the adjacent annular plates are in contact, the pressing plate is provided with an annular sealing bag, the annular sealing bag is located inside the suppo...

Embodiment 2

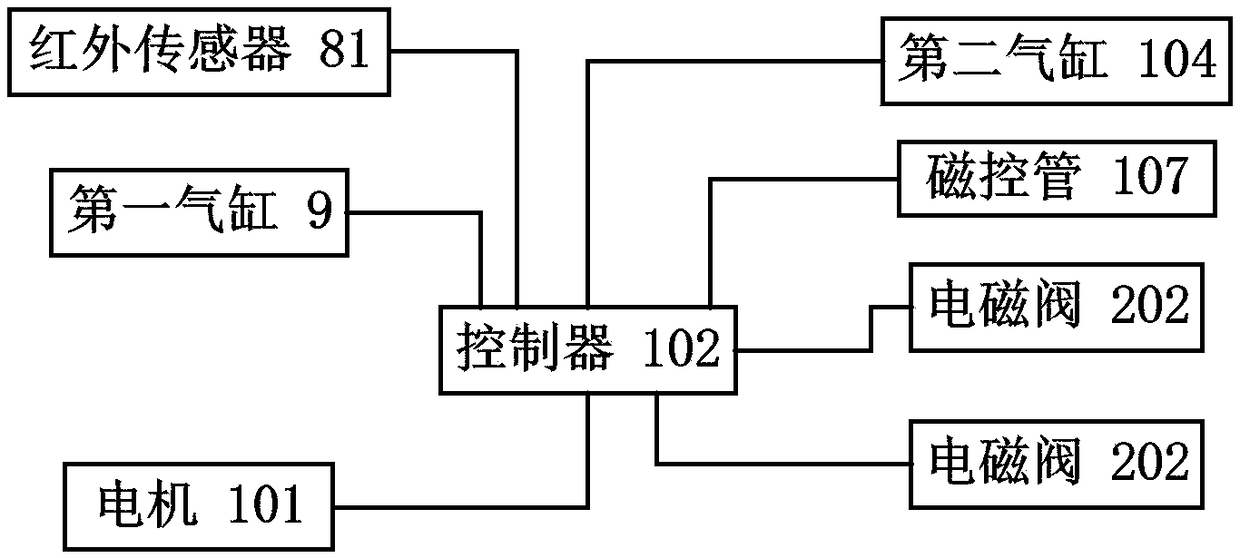

[0042] Embodiment 2 includes all structure and method parts of embodiment 1, such as figure 1 , image 3 As shown, Embodiment 2 also includes a first pole 8 located on the ground on the left side of the telescopic shroud, and an infrared sensor 81 is arranged on the first pole; Telescopic rod connection of cylinder 9;

[0043] A motor 101 is arranged on the ground at the bottom of the base, and the rotating shaft of the motor is fixedly connected to the middle of the base. The first cylinder, the motor and the infrared sensor are all electrically connected to the controller 102, and the controller is electrically connected to the memory.

[0044] Also include the following steps:

[0045] When the motor is in the initial state, the marking line set on the base is aligned with the first column. At this time, the rotation angle of the base is 0; the controller controls the motor to drive the base to rotate counterclockwise at an angular interval of W=6°. When the base rotates...

Embodiment 3

[0047] Embodiment 3 comprises all structures and method parts of embodiment 2, as figure 1 , image 3 Shown, also comprise the second upright pole 103 that is located on the ground on the right side of telescopic coaming board, be provided with magnetron 107 on the second upright pole, magnetron and be located at the second cylinder of the second upright pole bottom The telescopic link of 104 is connected, and the magnetron and the second cylinder are all electrically connected with the controller.

[0048] Also include the following steps:

[0049] When the motor is in the initial state, the angle between the marking line and the position of the second column is 180 degrees, so that the initial strokes of the first cylinder and the second cylinder are the same;

[0050] The controller drives the motor to drive the base counterclockwise with an angle of a+180°, and sets the stroke of the second cylinder to b, so that the magnetron is aligned with each sealed bag where the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com