High pressure holding furnace of low pressure casting machine

A low-pressure casting machine and holding furnace technology, applied in the field of casting, can solve the problems that product quality cannot be guaranteed, heating and heat preservation heat conduction efficiency is low, and high-strength castings cannot be satisfied, so as to achieve convenient setting and gating system optimization, increase temperature, increase intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

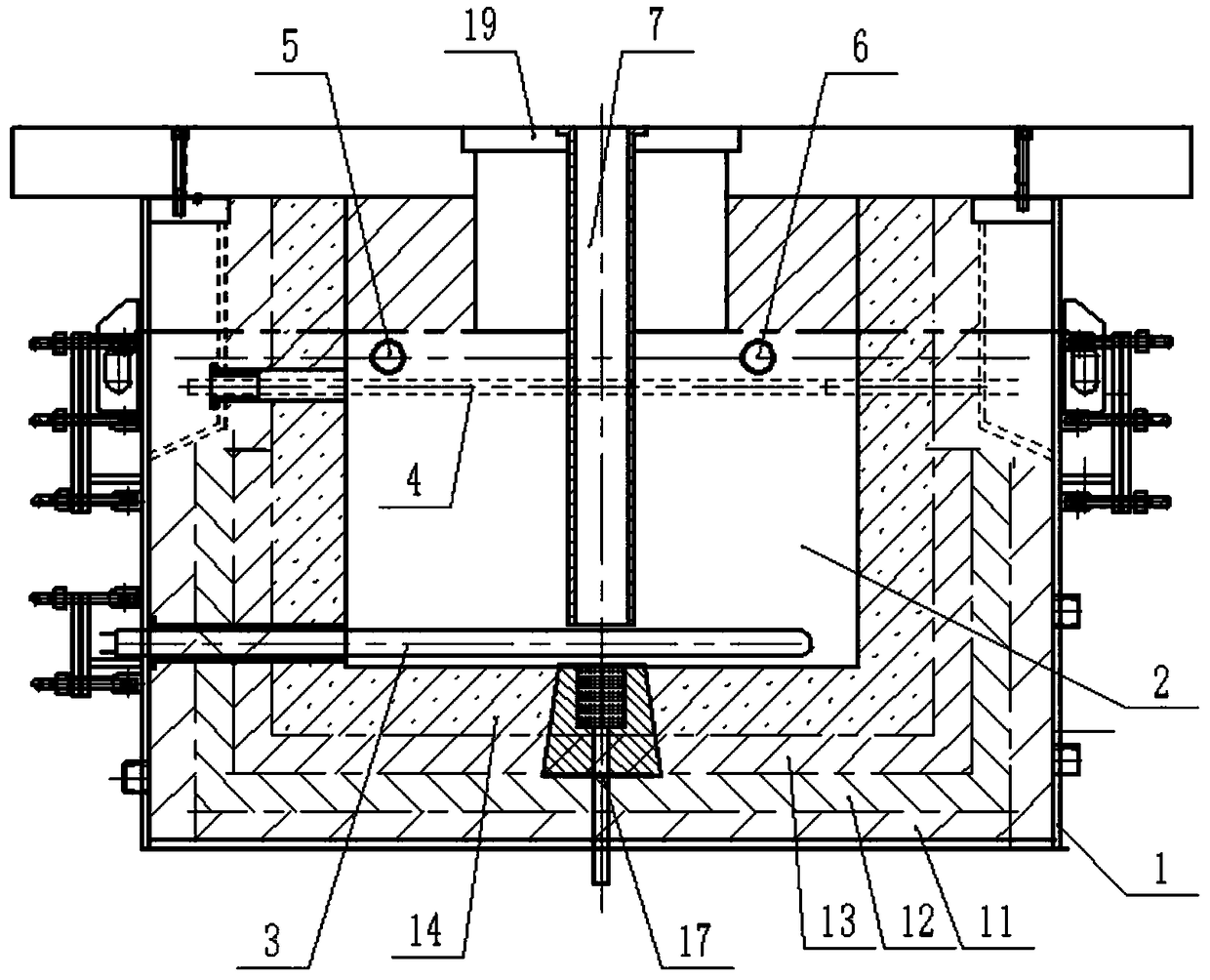

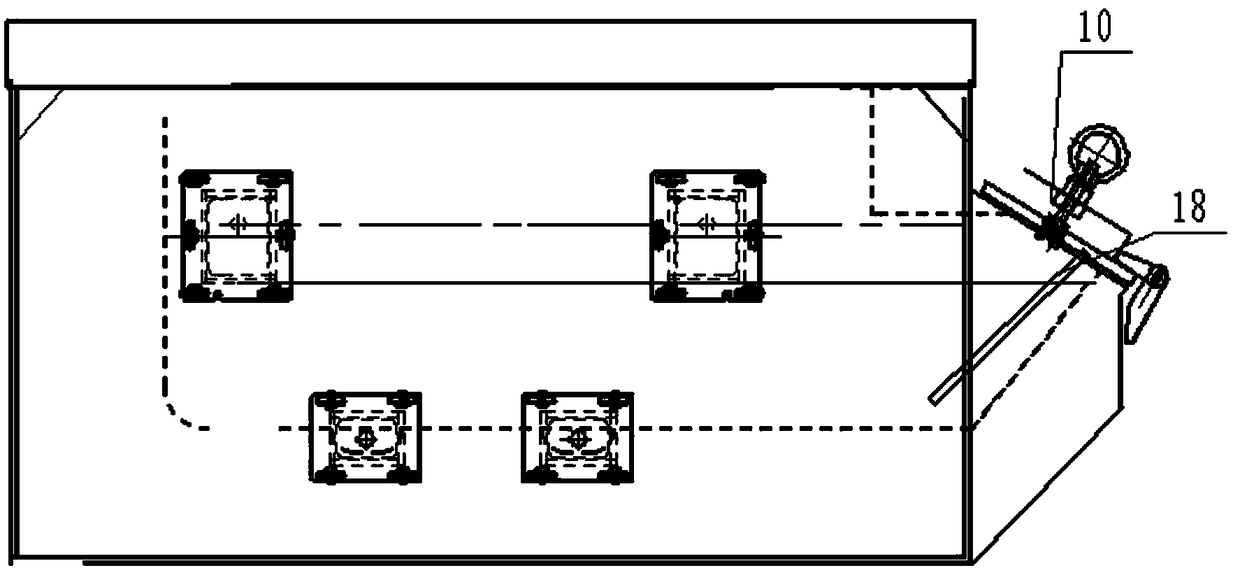

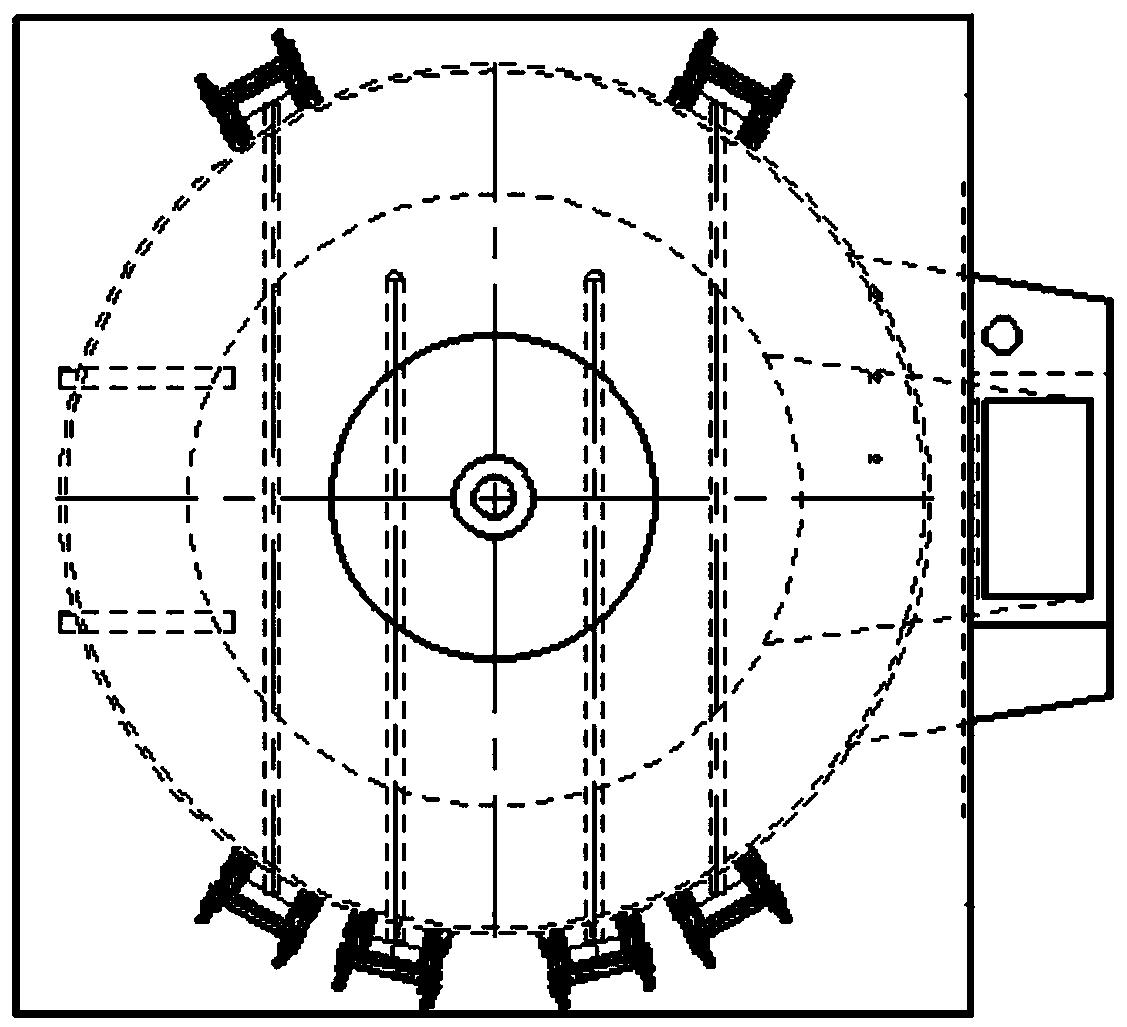

[0032] Such as Figure 1 to Figure 4 As shown, a high-pressure holding furnace for a low-pressure casting machine includes a holding furnace shell 1, a sealable pressurized chamber 2 is arranged inside the holding furnace shell 1, and an aluminum addition port 10 of the holding furnace shell 1 is arranged on the holding furnace shell On the side wall of the body 1 and communicated with the pressurized chamber 2, the top of the holding furnace shell 1 is provided with a liquid riser, and the liquid riser is provided with a riser pipe 7 to communicate with the pressurized chamber 2, and the aluminum liquid is in the pressurized chamber 2 , by pressurizing the pressurization chamber 2, the aluminum is hydraulically injected into the riser pipe 7, and connected with the casting mold through the riser pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com