Method for preparing micronano silver particles in aqueous solution system

A technology of micro-nano silver and aqueous solution, which is applied in the field of preparing micro-nano silver particles, can solve problems such as the need for heating or high-temperature hydrothermal reaction, and achieve the effects of high yield, uniform particle size distribution and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

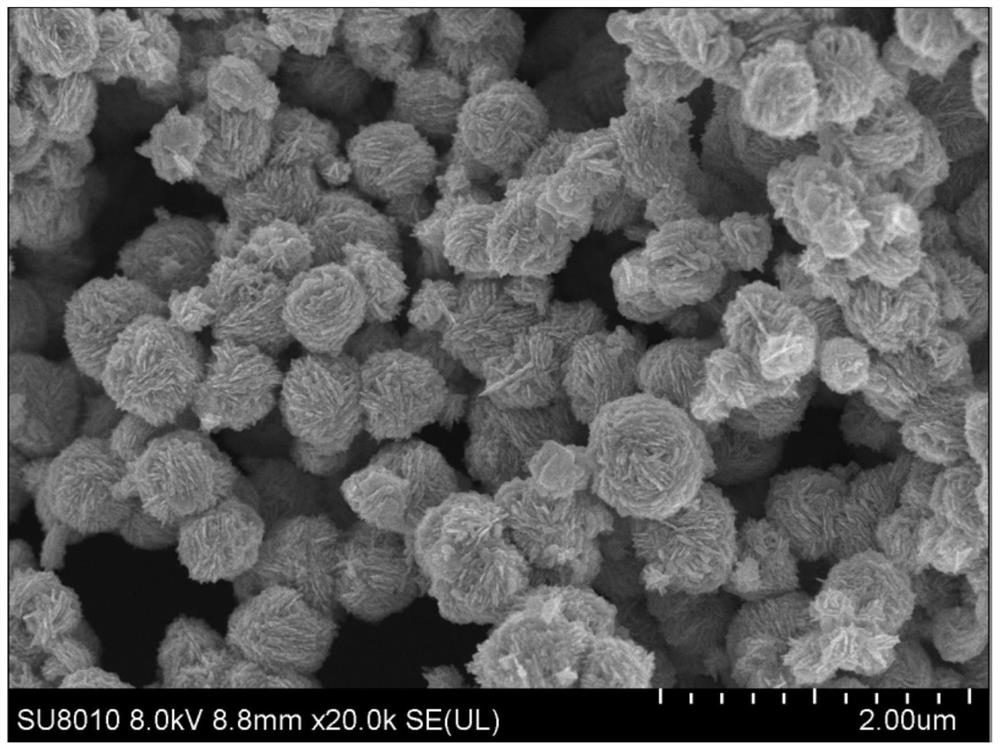

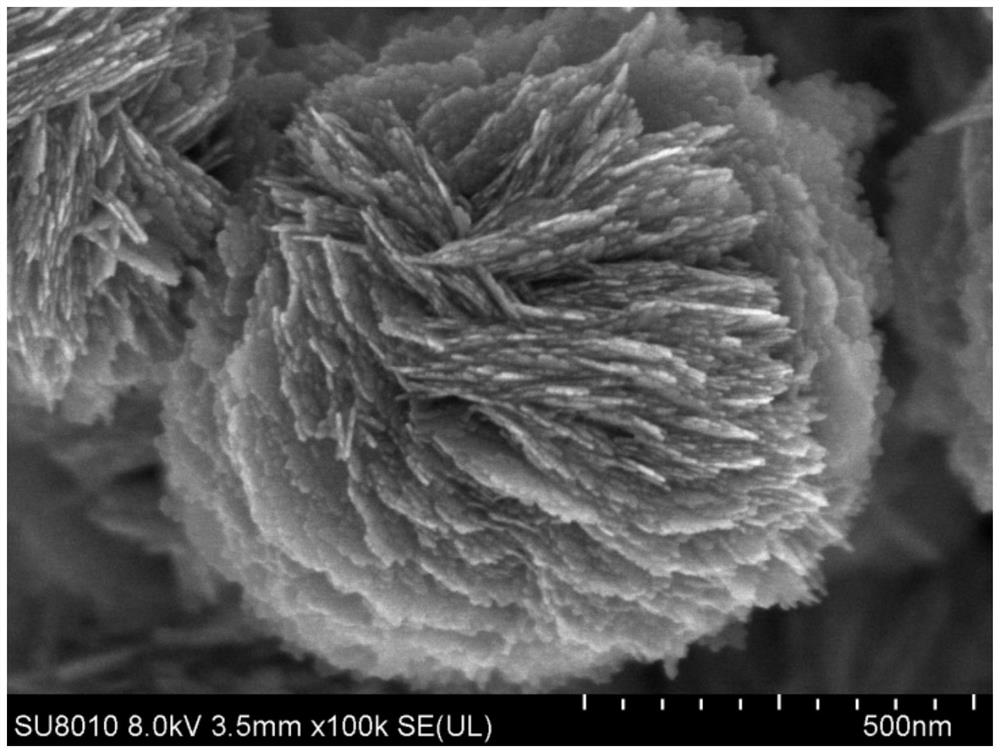

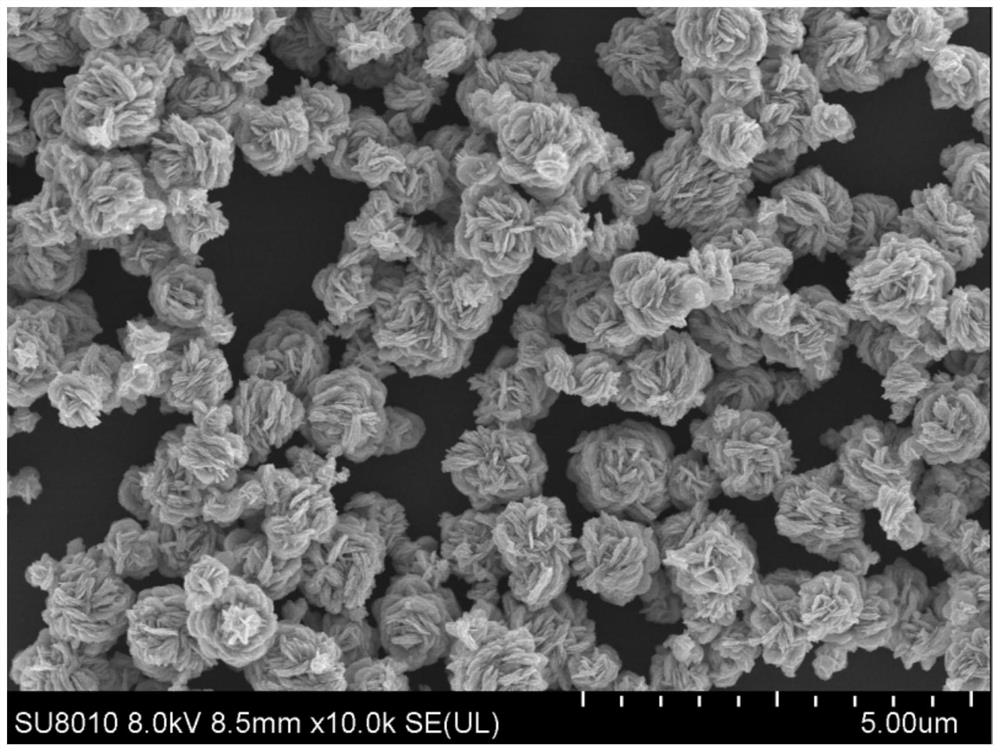

[0039] Weigh trisodium citrate and dissolve it in deionized water to prepare an aqueous solution of trisodium citrate with a concentration of 0.11 g / mL. Dissolve silver nitrate in deionized water to prepare a silver nitrate aqueous solution with a concentration of 0.5 g / mL. Take 40mL of trisodium citrate aqueous solution and 10mL of silver nitrate aqueous solution and mix first, and stir for 30min to obtain a uniform silver complex solution, which is a silver precursor solution. Hydrazine hydrate was added into deionized water to prepare a hydrazine hydrate reducing agent solution with a concentration of 6%. Then 50mL of reducing agent solution and 50mL of silver precursor solution were added dropwise to 200mL of water with a metering pump for a mixed reaction. The addition time was 15min, and then at a temperature of 10°C, under stirring at 600 rpm, the reaction was continued for 60min. , to obtain a uniform brown-black solution, and to obtain silver particles after post-tre...

Embodiment 2

[0041] Weigh trisodium citrate and dissolve it in deionized water to prepare an aqueous solution of trisodium citrate with a concentration of 0.16 g / mL. Dissolve silver nitrate in deionized water to prepare a silver nitrate aqueous solution with a concentration of 0.1 g / mL. Take 50mL of trisodium citrate aqueous solution and 50mL of silver nitrate aqueous solution and mix first, and stir for 30min to obtain a uniform silver complex solution, which is a silver precursor solution. Hydrazine hydrate was added into deionized water to prepare a 4% hydrazine hydrate reducing agent solution. Then 100mL of reducing agent solution and 100mL of silver precursor solution were added dropwise to 100mL of water with a metering pump for a mixed reaction, the addition time was 25min, and then at a temperature of 20°C, under stirring at 600 rpm, the stirring reaction was continued for 60min. A uniform brown-black solution is obtained, and silver particles are obtained after post-treatment, su...

Embodiment 3

[0043] Weigh disodium edetate and dissolve it in deionized water to prepare a disodium edetate aqueous solution with a concentration of 0.06 g / mL. Dissolve silver nitrate in deionized water to prepare a silver nitrate aqueous solution with a concentration of 0.1 g / mL. Mix 60 mL of disodium edetate aqueous solution with 50 mL of silver nitrate aqueous solution, and stir for 30 minutes to obtain a uniform silver complex solution, which is a silver precursor solution. Hydrazine hydrate was added into deionized water to prepare a hydrazine hydrate reducing agent solution with a concentration of 5%. Then 110mL of reducing agent solution and 110mL of silver precursor solution were added dropwise to 80mL of water with a metering pump for a mixed reaction. The addition time was 30min, and then at a temperature of 15°C, under stirring at 600 rpm, the stirring reaction was continued for 60min. The reaction is over. Then wash 2 times three times with water, and obtain silver particles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com