Oblique oil hole drilling jig and method for machining inner ring bearing oblique oil hole through oblique oil hole drilling jig

A technology of inclined oil holes and drilling molds, which is applied in the direction of drilling molds for workpieces, etc., which can solve the problems of drill bit offset, easy chipping or breaking of the drill bit, and difficulty in ensuring the verticality of the hole, so as to avoid Chipping or breaking, the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

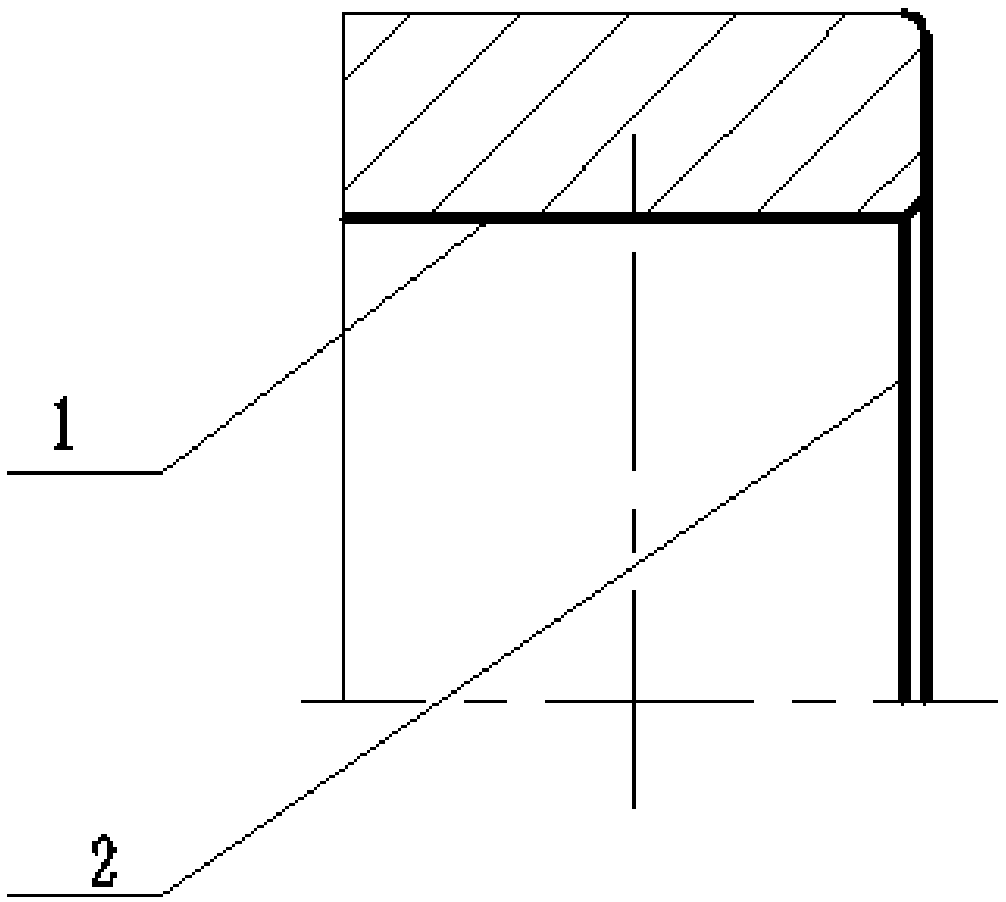

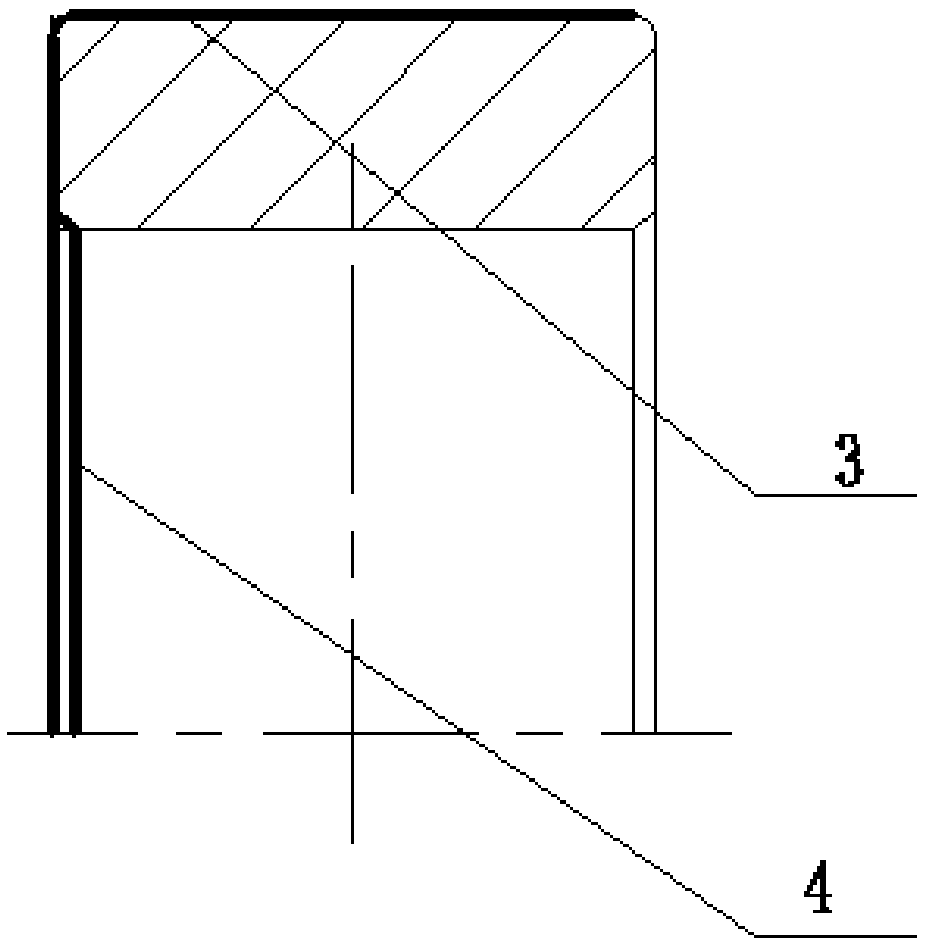

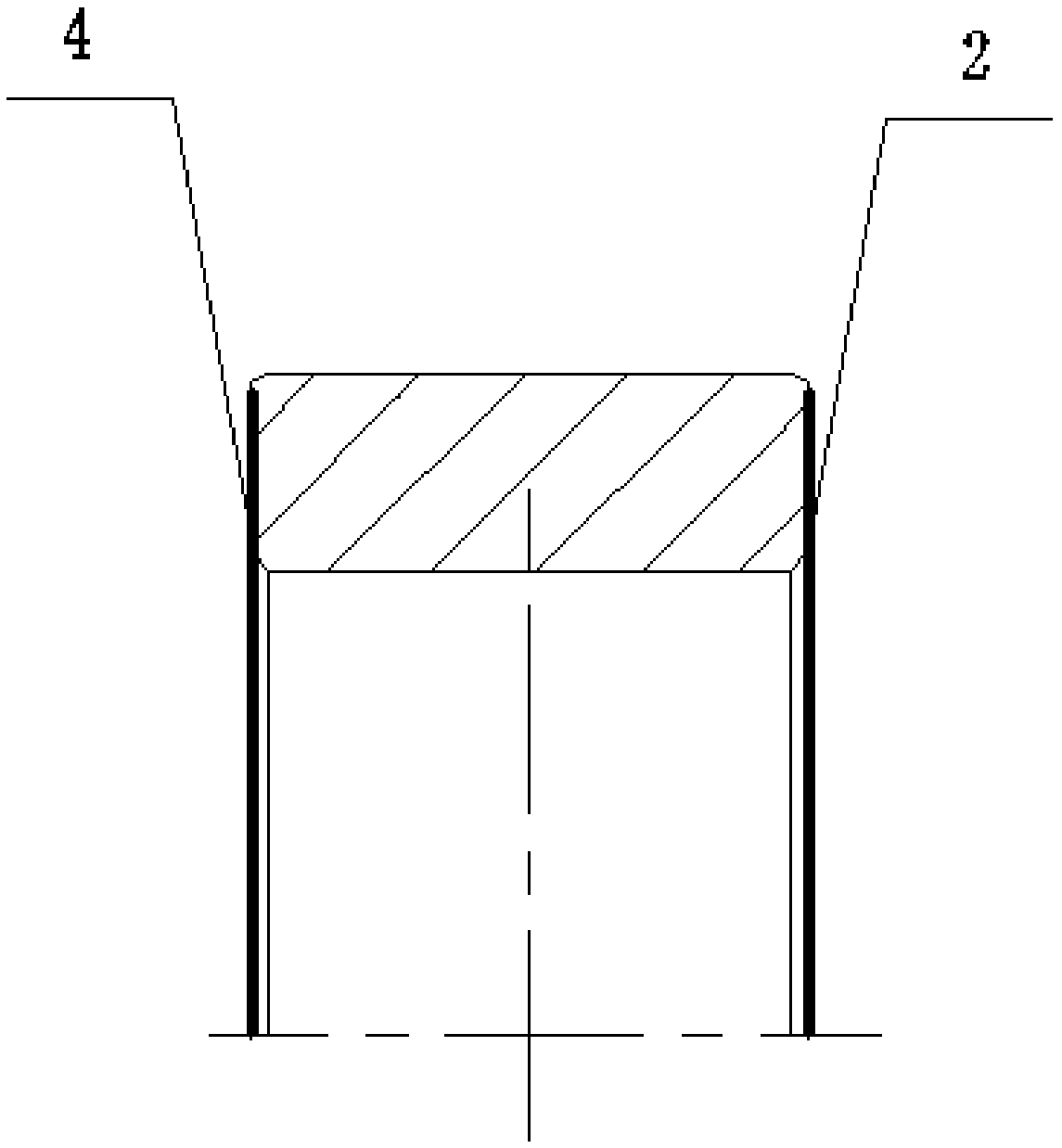

[0048] Specific implementation mode one: combine Figure 10 to Figure 13 Describe this embodiment mode, a kind of oblique oil hole drilling template described in this embodiment comprises drilling template body 13, pressure plate 14, nut 15 and bolt 16, and the upper surface of drilling template body 13 is provided with processing groove 13-1, and bolt 16 vertical It is directly arranged in the processing groove 13-1, and the pressing plate 14 and the nut 15 are successively set on the top of the bolt 16. The drill template body 13 is a cylinder with a regular hexagonal cross section, and three non-adjacent outer walls of the drill template body 13 A guide through hole 18 is provided in each case.

[0049] The jig body 13 is designed as a hexahedral structure. When drilling the inclined oil hole 8, the workpiece is placed in the processing groove 13-1, and the positioning pin 19 is inserted into the end surface of the workpiece from the dowel hole 17 at the bottom of the jig b...

specific Embodiment approach 2

[0050] Specific implementation mode two: combination Figure 10 to Figure 13 To illustrate this embodiment, the angle a between the outer wall 18 - 1 and the horizontal plane corresponding to each guide through hole 18 of an inclined oil hole drilling jig described in this embodiment is 37°±5′. This angle setting is used to ensure the angle of drilling inclined oil holes. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0051] Specific implementation mode three: combination Figure 10 to Figure 13 To illustrate this embodiment, the processing groove 13-1 of the inclined oil hole drilling jig described in this embodiment is a circular groove. The inner contour of the processing groove 13-1 is adapted to the outer contour of the workpiece, and is used for placing the workpiece to be processed. Other components and connections are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com