Roller surface processing device

A technology for processing device and roll surface, which is applied in the direction of grinding drive device, grinding/polishing safety device, and machine tool designed for grinding the rotating surface of workpiece, etc. The problem of equalization can be achieved to avoid the deformation of the main body of the roll, avoid environmental pollution, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

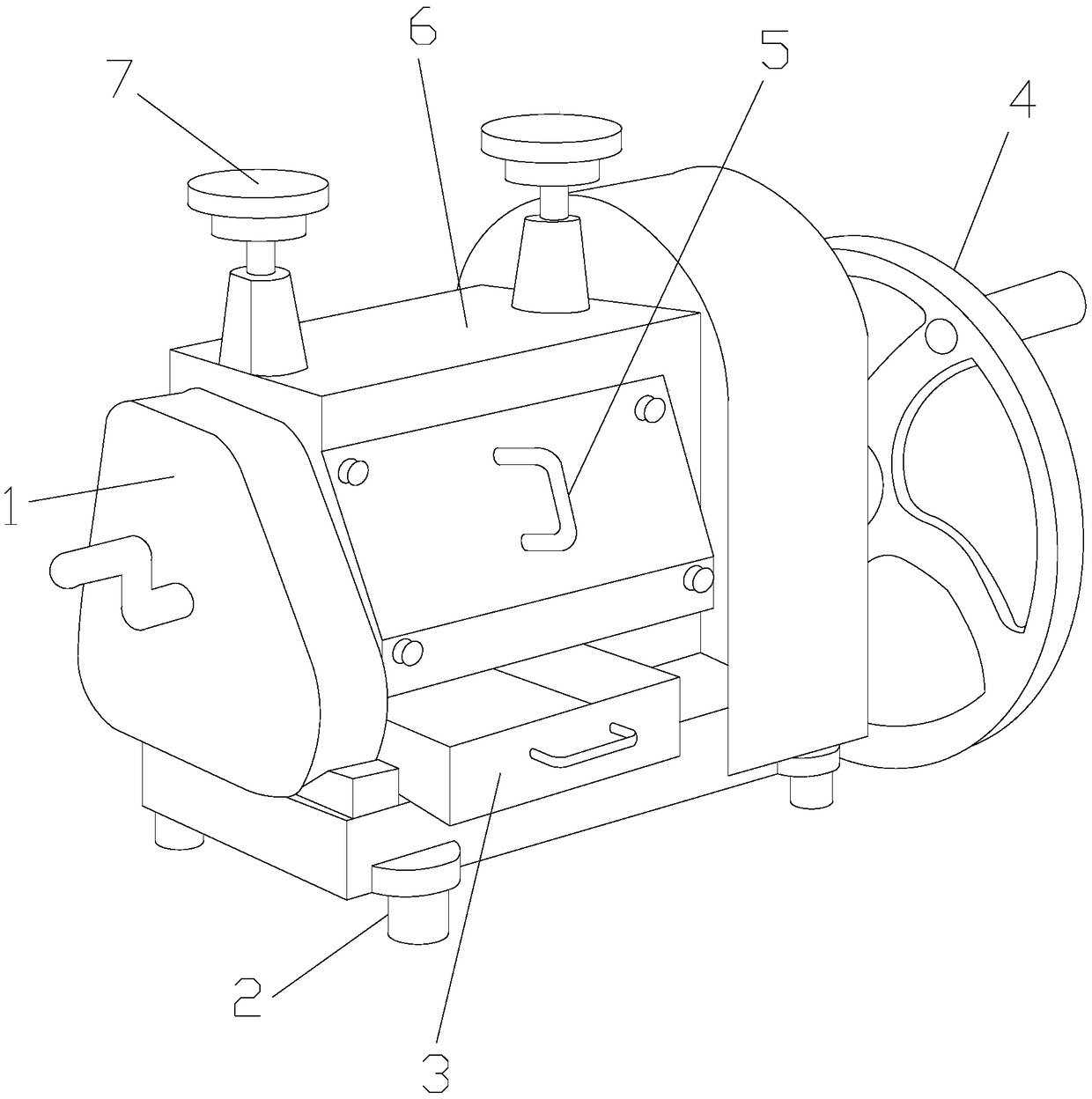

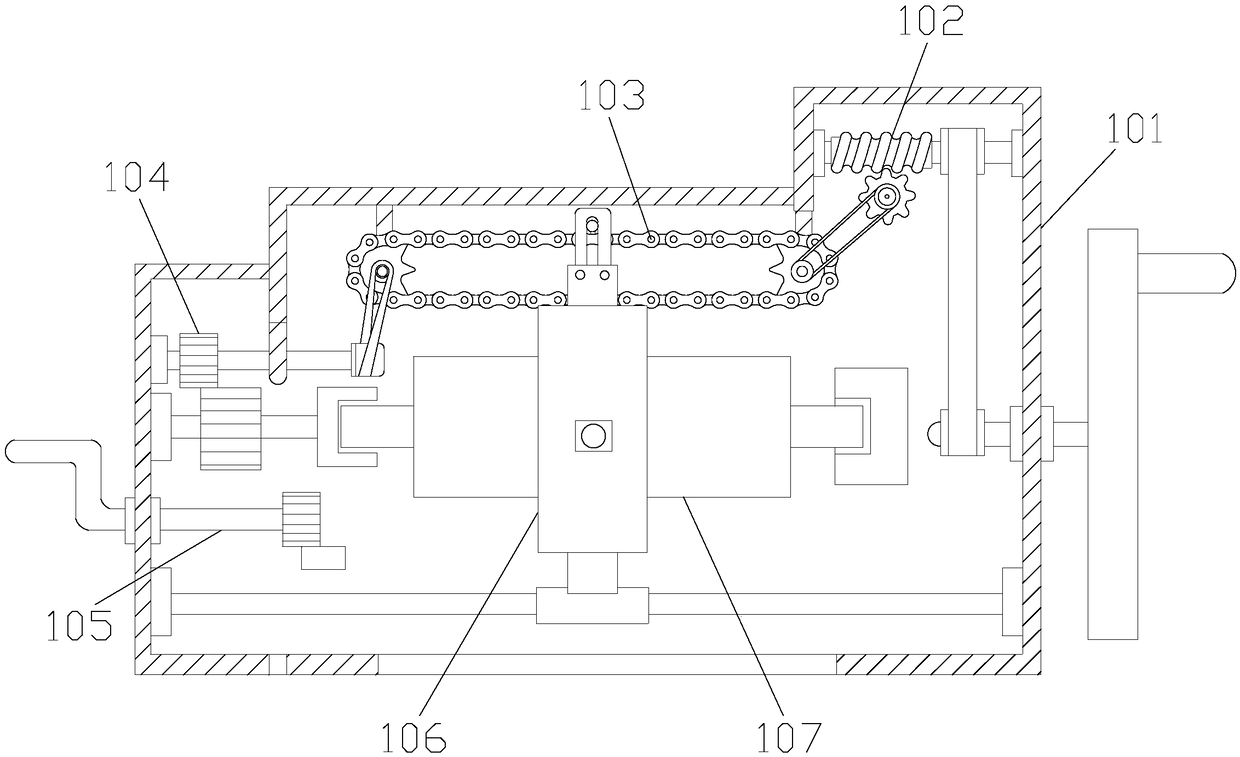

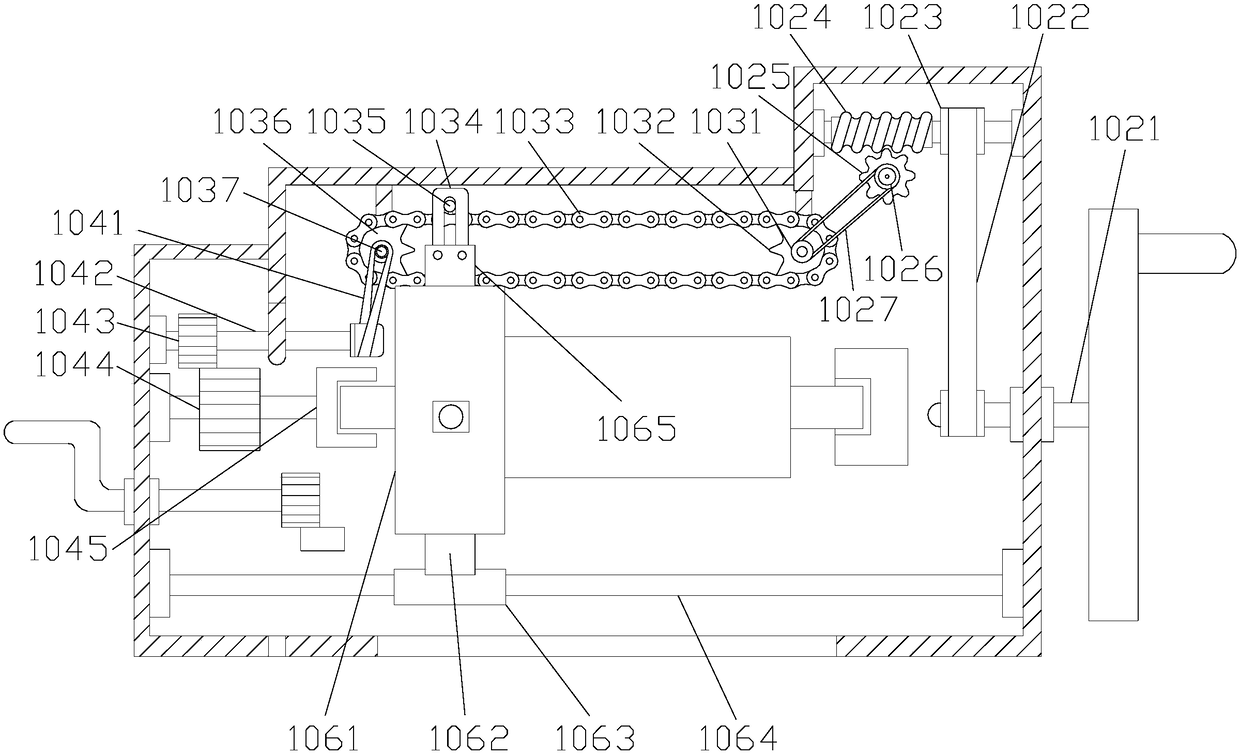

[0028] see Figure 1-Figure 5 , the present invention provides a roll surface treatment device, the structure of which includes a roll processing machine 1, a support leg 2, a dust collection drawer 3, a large hand wheel 4, a handle 5, a dust-proof flip cover 6, and a reinforcement screw 7;

[0029] The bottom end of the roll processing machine 1 is provided with a support foot 2, the roll processing machine 1 and the support foot 2 are welded, and the front end of the roll processing machine 1 is provided with a dust collection drawer 3, the The roll processing machine 1 and the dust collection drawer 3 are movably connected, and the right side of the roll processing machine 1 is provided with a large hand wheel 4, and the roll processing machine 1 and the large hand wheel 4 adopt clearance fit, and the The surface of the roll processing machine 1 is provided with a dust-proof flip 6, the roll processing machine 1 and the dust-proof flip 6 are hingedly connected, the front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com