Testing device

A testing device and testing mechanism technology, which is applied in the direction of optical testing flaws/defects, manipulators, chucks, etc., and can solve problems such as cumbersome loading and unloading operations and manual judgment errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

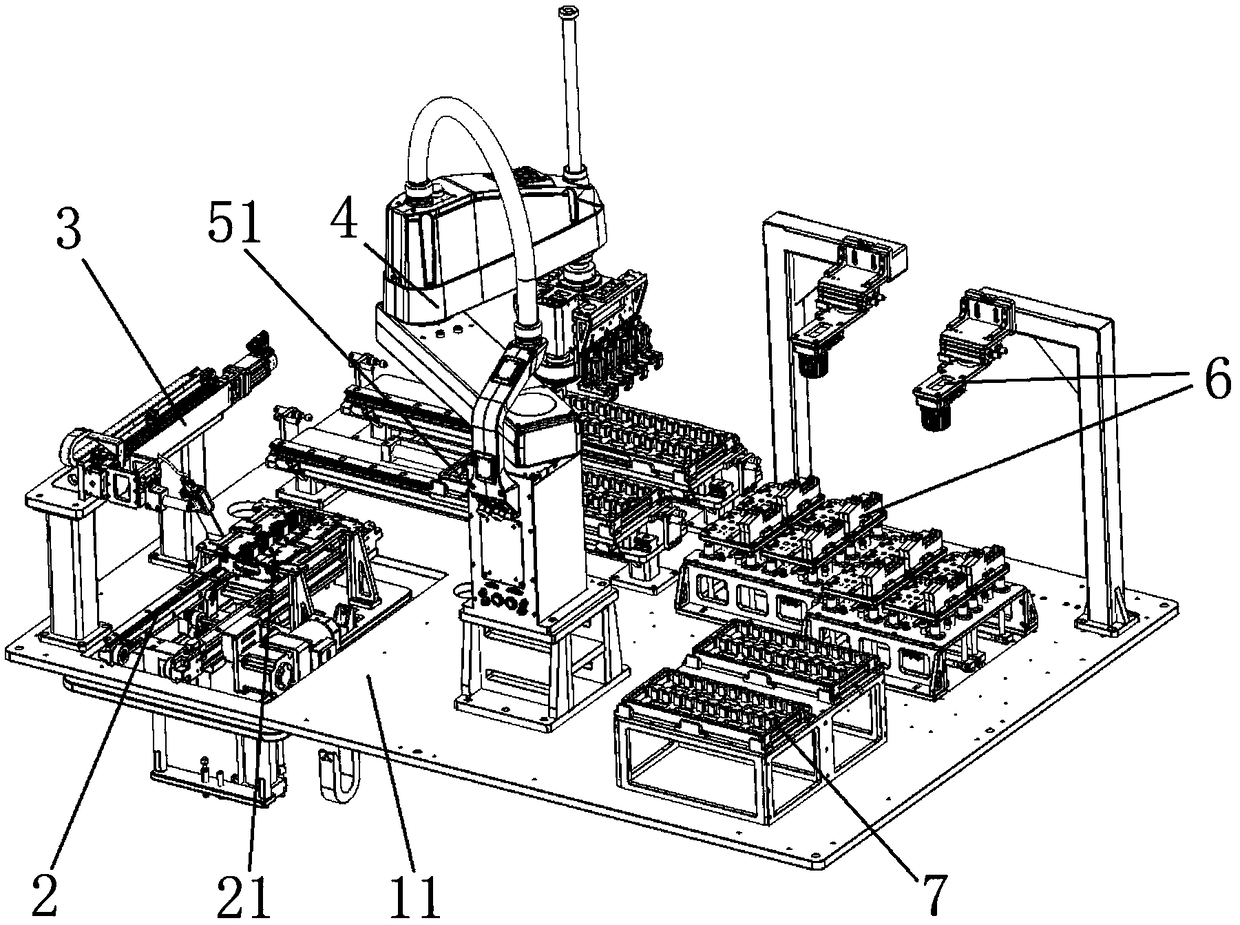

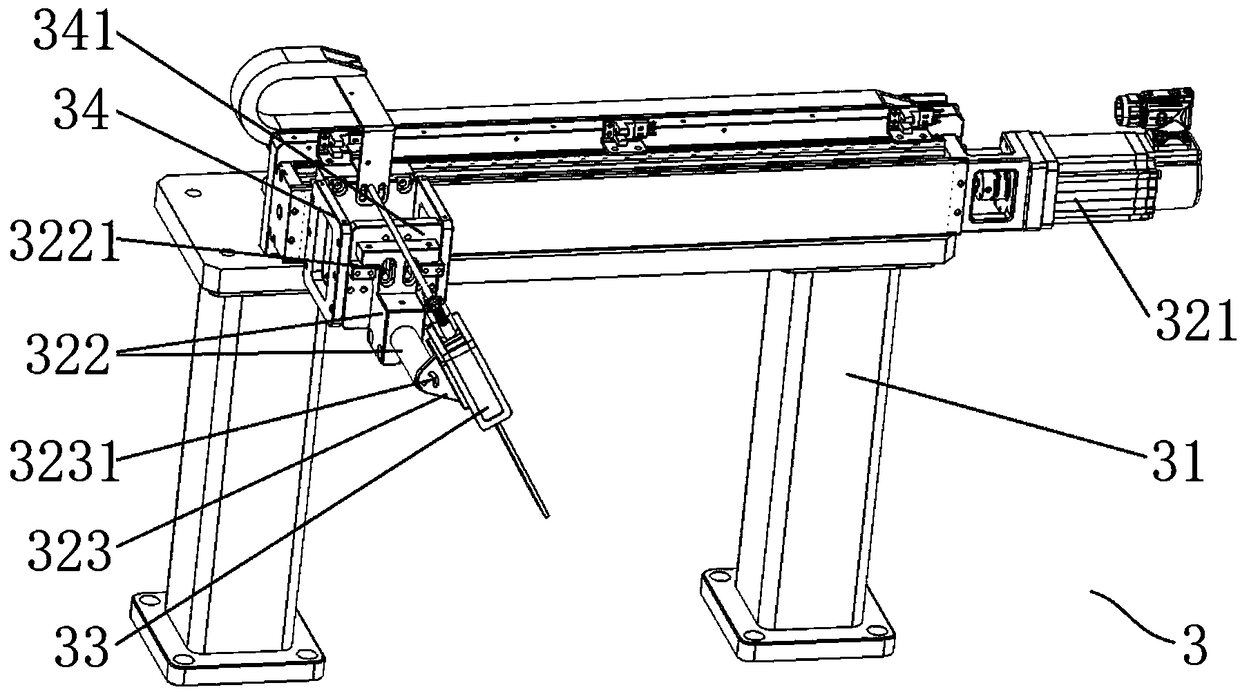

[0055] Such as Figure 1 to Figure 11 The shown test device includes a casing 1 and a workbench 11 arranged in the casing 1, wherein the workbench 11 is provided with a transmission line 2, a scanning identification mechanism 3, a manipulator 4, a workpiece buffer area, a testing mechanism 6 and other Qualified artifact storage area. The transmission line 2 in this embodiment is provided with a transmission line carrier 21, which is used to transport the workpieces in the transmission line carrier 21 to the testing device after being processed by other steps; the scanning identification mechanism 3 is used to scan the The identification code on the workpiece in the wire carrier 21 and sends the workpiece information of the workpiece obtained to the testing mechanism 6; the manipulator 4 transports the workpiece between each mechanism; the workpiece buffer area is used for buffering the workpiece; the testing mechanism 6 obtains and The corresponding test information, and perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com